2021 High quality Si-TPV - Si-TPV 3420-90A silky touch dynamic vulcanizated thermoplastic silicone-based elastomers – Silike

2021 High quality Si-TPV - Si-TPV 3420-90A silky touch dynamic vulcanizated thermoplastic silicone-based elastomers – Silike Detail:

DESCRIPTION

SILIKE Si-TPV® thermoplastic elastomer is a patented dynamic vulcanized thermoplastic silicone-based elastomer which made by a special compatible technology to help silicone rubber dispersed in TPU evenly as a 2~3 micron particles under microscope.Those unique materials combine the strength,toughness and abrasion resistance of any thermoplastic elastomer with desirable properties of silicone:softness,silky feel,UV light and chemicals resistance which can be recycled and reused in traditional manufacturing processes.

Si-TPV®3420-90A thermoplastic elastomer is a material with good abrasion and chemical resistance which can excellent bond to PC,ABS,TPU and similar polar substrates. It is a product developed for silky touch overmolding on wearable electronics, accessory cases for electronic devices, especially for phone cases.

APPLICATIONS

Solution for soft touch over molding on smart phones, portable electronic cases, ear buds, and other wearable electronic devices.

TYPICAL PROPERTIES

|

Test* |

Property |

Unit |

Result |

|

ISO 868 |

Hardness (15 seconds) |

Shore A |

88 |

|

ISO 1183 |

Specific Gravity |

– |

1.21 |

|

ISO 1133 |

Melt Flow Index 10 kg & 190°C |

g/10 min |

7.6 |

|

ISO 37 |

MOE ( Modulus of elasticity) |

MPa |

17.2 |

|

ISO 37 |

Tensile Strength |

MPa |

24 |

|

ISO 37 |

Tensile Stress @ 100% Elongation |

MPa | 8.4 |

|

ISO 37 |

Elongation at break |

% | 485 |

| ISO 34 | Tear Strength | kN/m | 103 |

| ISO 815 | Compression Set 22 hours @ 23°C | % | 32 |

*ISO: International Standardization Organization ASTM: American Society for Testing and Materials

FEATURES & BENEFITS

(1) Soft silky feel

(2) Good scratch resistance

(3) Excellent bonding to PC, ABS

(4) Super hydrophobic

(5) Stain resistance

(6) UV stable

HOW TO USE

• Injection Molding Processing Guide

| Drying Time |

2–6 hrs |

| Drying Temperature |

80–100°C |

| Feed Zone Temperature |

170–190°C |

| Center Zone Temperature |

180–200°C |

| Front Zone Temperature |

190–200°C |

| Nozzle Temperature |

190–200°C |

| Melt Temperature |

200°C |

| Mold Temperature |

30–50°C |

| Injection Speed |

FAST |

These process conditions may vary with individual equipment and processes.

• Secondary Processing

As a thermoplastic material, Si-TPV® material can be secondary processed for ordinary products

• Injection Molding Pressure

The holding pressure largely depends on the geometry, thickness and gate location of the product. The holding pressure should be set to a low value at first, and then slowly increase until no related defects are seen in the injection molded product. Due to the elastic properties of the material, excessive holding pressure may cause serious deformation of the gate part of the product.

• Back pressure

It is recommended that the back pressure when the screw is retracted should be 0.7-1.4Mpa, which will not only ensure the uniformity of melt melting, but also ensure that the material is not severely degraded by shear. The recommended screw speed of Si-TPV® is 100-150rpm to ensure the complete melting and plasticization of the material without material degradation caused by shear heating.

HANDLING PRECAUTIONS

A desiccant dehumidifying dryer is recommended for all drying.

Product safety information required for safe use is not included in this document. Before handling, read product and safety data sheets and container labels for safe use, physical and health hazard information. the safety data sheet is available on the silike company website at siliketech.com ,or from distributor, or by calling Silike customer service.

USABLE LIFE AND STORAGE

Transport as non-hazardous chemical. Store in a cool , well ventilated place. Original characteristics remain intact for 24 months from the production date , if kept in recommend storage.

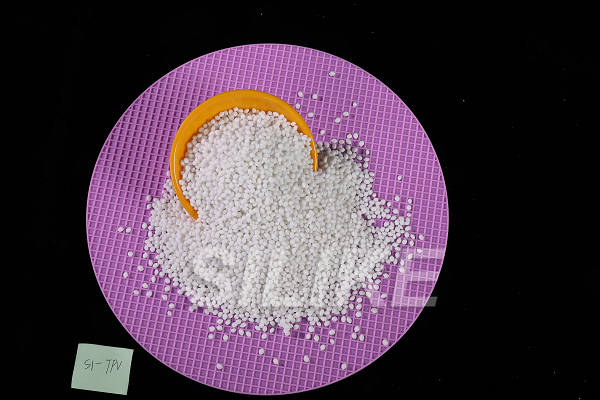

PACKAGING INFORMATION

25KG / bag , craft paper bag with PE inner bag.

LIMITATIONS

This product is neither tested nor represented as suitable for medical or pharmaceutical uses.

LIMITED WARRANTY INFORMATION – PLEASE READ CAREFULLY

The information contained herein is offered in good faith and is believed to be accurate. However, because conditions and methods of use of our products are beyond our control, this information should not be used in substitution for customer’s tests to ensure that our products are safe, effective, and fully satisfactory for the intended end use. Suggestions of use shall not be taken as inducements to infringe any patent.

Product detail pictures:

Related Product Guide:

Our purpose would be to offer good quality products at competitive price ranges, and top-notch support to clients around the whole world. We're ISO9001, CE, and GS certified and strictly adhere to their good quality specifications for 2021 High quality Si-TPV - Si-TPV 3420-90A silky touch dynamic vulcanizated thermoplastic silicone-based elastomers – Silike , The product will supply to all over the world, such as: Curacao, Czech republic, Kuala Lumpur, We believe that good business relationships will lead to mutual benefits and improvement for both parties. We have established long-term and successful cooperative relationships with many customers through their confidence in our customized services and integrity in doing business. We also enjoy a high reputation through our good performance. Better performance will be expected as our principle of integrity. Devotion and Steadiness will remain as ever.

FREE SILICONE ADDITIVES AND Si-TPV SAMPLES MORE THAN 100 GRADES

Sample type

$0

- 50+

grades Silicone Masterbatch

- 10+

grades Silicone Powder

- 10+

grades Anti-scratch Masterbatch

- 10+

grades Anti-abrasion Masterbatch

- 10+

grades Si-TPV

- 8+

grades Silicone Wax

We have been looking for a professional and responsible supplier, and now we find it.