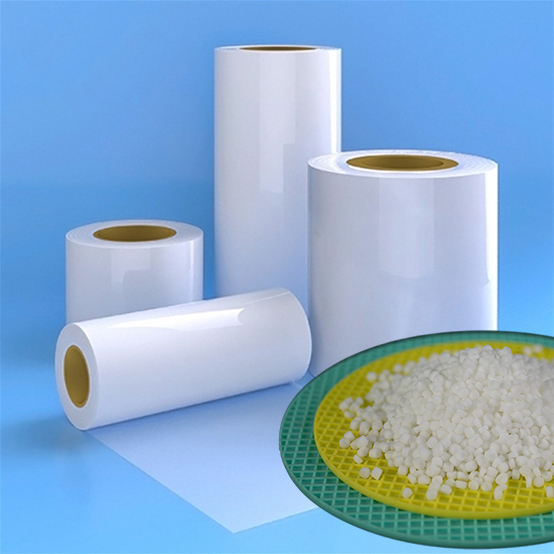

Silicone Masterbatch LYSI Series

Silicone Masterbatch ( Siloxane Masterbatch ) LYSI series is a pelletized formulation with 20~65% ultra high molecular weight siloxane polymer dispersed in various resin carrier. It is widely used as an efficient processing additive in it’s compatible resin system to improve the processing properties and modify surface quality.

Compare to conventional lower molecular weight Silicone / Siloxane additives,like Silicone oil, silicone fluids or other type processing aids, SILIKE Silicone Masterbatch LYSI series are expected to give improved benefits, eg,. Less screw slippage , improved mold release, reduce die drool, a lower coefficient of friction, fewer paint and printing problems, and a broader range of performance capabilities.

| Product name | Appearance | Effective component | Active content | Carrier resin | Recommend Dosage(W/W) | Application scope |

| Silicone Masterbatch LYSI-704 | White pellet | Siloxane polymer | POM | 0.5~5% | Engineering plastics, such as PA, POM, and others | |

| Silicone Masterbatch SC920 | White Pellet | -- | -- | -- | 0.5~5% | -- |

| Silicone Masterbatch LYSI-401 | White pellet | Siloxane polymer | 50% | LDPE | 0.5~5% | PE PP PA TPE |

| Silicone Masterbatch LYSI-402 | White pellet | Siloxane polymer | 50% | EVA | 0.5~5% | PE PP PA EVA |

| Silicone Masterbatch LYSI-403 | White pellet | Siloxane polymer | 50% | TPEE | 0.5~5% | PET PBT |

| Silicone Masterbatch LYSI-404 | White pellet | Siloxane polymer | 50% | HDPE | 0.5~5% | PE PP TPE |

| Silicone Masterbatch LYSI-405 | White pellet | Siloxane polymer | 50% | ABS | 0.5~5% | ABS AS |

| Silicone Masterbatch LYSI-406 | White pellet | Siloxane polymer | 50% | PP | 0.5~5% | PE PP TPE |

| Silicone Masterbatch LYSI-307 | White pellet | Siloxane polymer | 50% | PA6 | 0.5~5% | PA6 |

| Silicone Masterbatch LYSI-407 | White pellet | Siloxane polymer | 30% | PA6 | 0.5~5% | PA |

| Silicone Masterbatch LYSI-408 | White pellet | Siloxane polymer | 30% | PET | 0.5~5% | PET |

| Silicone Masterbatch LYSI-409 | White pellet | Siloxane polymer | 50% | TPU | 0.5~5% | TPU |

| Silicone Masterbatch LYSI-410 | White pellet | Siloxane polymer | 50% | HIPS | 0.5~5% | HIPS |

| Silicone Masterbatch LYSI-311 | White pellet | Siloxane polymer | 50% | POM | 0.5~5% | POM |

| Silicone Masterbatch LYSI-411 | White pellet | Siloxane polymer | 30% | POM | 0.5~5% | POM |

| Silicone Masterbatch LYSI-412 | White pellet | Siloxane polymer | 50% | LLDPE | 0.5~5% | PE, PP, PC |

| Silicone Masterbatch LYSI-413 | White pellet | Siloxane polymer | 25% | PC | 0.5~5% | PC, PC/ABS |

| Silicone Masterbatch LYSI-415 | White pellet | Siloxane polymer | 50% | SAN | 0.5~5% | PVC, PC, PC&ABS |

| Silicone Masterbatch LYSI-501 | White pellet | Siloxane polymer | -- | PE | 0.5~6% | PE PP PA TPE |

| Silicone Masterbatch LYSI-502C | White pellet | Siloxane polymer | -- | EVA | 0.2~5% | PE PP EVA |

| Silicone Masterbatch LYSI-506 | White pellet | Siloxane polymer | -- | PP | 0.5~7% | PE PP TPE |

| Silicone Masterbatch LYPA-208C | White pellet | Siloxane polymer | 50% | LDPE | 0.2~5% | PE, XLPE |

100% Pure PFAS free PPA / fluorine free PPA product

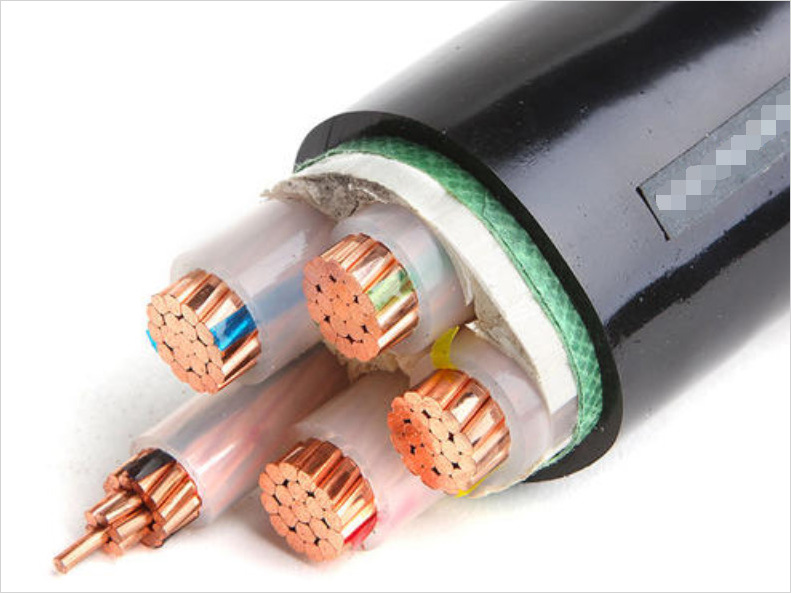

SILIMER series products are PFAS-free polymer processing aids (PPA) which were researched and developed by Chengdu Silike. This series of products is Pure modified Copolysiloxane, with properties of polysiloxane and the polar effect of the modified group, the products will migrate to the equipment surface, and work as a polymer processing aid(PPA). It is recommended to be diluted into a certain content masterbatch first, then used in polyolefin polymers, with a small addition, the melting flow, processability, and lubricity of the resin can effectively improved as well as eliminate meltfracture, greater wear resistance, smaller friction coefficient, extend equipment cleaning cycle, shorten downtime, and higher output and a better products surface, a perfect choice to replace pure fluorine-based PPA.

| Product name | Appearance | Effective component | Active content | Carrier resin | Recommend Dosage(W/W) | Application scope |

| PFAS free PPA SILIMER9400 | Off-white pellet | copolysiloxane | 100% | -- | 300-1000ppm | Polyolefins and recycled polyolefin resins, Blown, cast, and multilayer films. Fiber and monofilament extrusion, Cable and pipe extrusion, Masterbatch, Compounding ,And Fluorinated PPA application related fields, etc |

| PFAS free PPA SILIMER9300 | Off-white pellet | copolysiloxane | 100% | -- | 300-1000ppm | films,Pipes,Wires |

| PFAS free PPA SILIMER9200 | Off-white pellet | copolysiloxane | 100% | -- | 300-1000ppm | films,Pipes,Wires |

| PFAS free PPA SILIMER9100 | Off-white pellet | copolysiloxane | 100% | -- | 300-100ppm | PE films,Pipes,Wires |

PFAS FREE / fluorine free PPA masterbatches

SILIMER series PPA masterbatch is a new type of processing aid containing modified copolysiloxane functional groups with different carriers like PE, PP..eg. It can migrate to the processing equipment and have an effect during processing by taking advantage of the excellent initial lubrication effect of polysiloxane and the polarity effect of modified groups. A small addition of it can effectively improve the fluidity and processability, reduce the die drool, and improve the phenomenon of shark skin, it has been widely used to improve the lubrication and surface characteristics of plastic extrusion. Typical applications like plastic film, pipe, masterbatches, artificial grass, resins, sheets, wire&cables...eg.

| Product name | Appearance | Effective component | Active content | Carrier resin | Recommend Dosage(W/W) | Application scope |

| PFAS free PPA SILIMER 9406 | Off-white pellet | copolysiloxane | -- | PP | 0.5~10% | PP films. Pipes,Wires, color masterbatch and artificial grass |

| PFAS free PPA SILIMER9301 | Off-white pellet | copolysiloxane | -- | LDPE | 0.5~10% | PE films,Pipes,Wires |

| PFAS free PPA SILIMER9201 | Off-white pellet | copolysiloxane | -- | LDPE | 1~10% | PE films,Pipes,Wires |

| PFAS free PPA SILIMER5090H | Off-white pellet | copolysiloxane | -- | LDPE | 1~10% | PE films,Pipes,Wires |

| PFAS free PPA SILIMER5091 | Off-white pellet | copolysiloxane | -- | PP | 0.5~10% | PP films,Pipes,Wires |

| PFAS free PPA SILIMER5090 | Off-white pellet | copolysiloxane | -- | LDPE | 0.5~10% | PE films,Pipes,Wires |

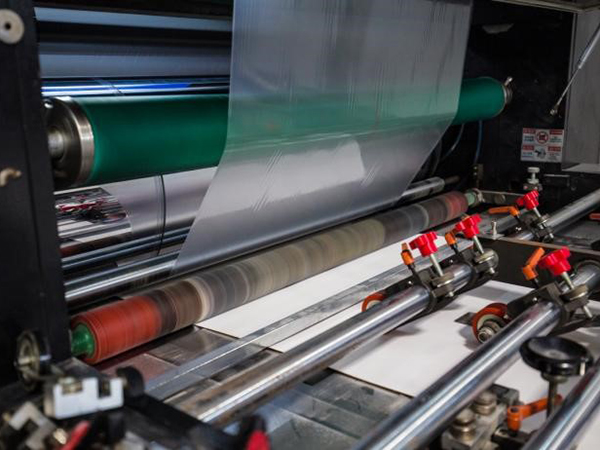

SILIMER series Super Slip Masterbatch

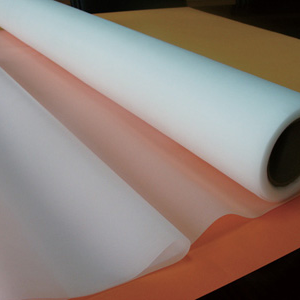

SILlKE SILIMER series super slip and anti-blocking masterbatch is a product particularly researched and developed for plastic films. This product contains a specially modified silicone polymer as the active ingredient to overcome the common problems that traditional smoothing agents have, such as precipitation and high-temperature stickiness, etc. It can significantly improve the anti-blocking & smoothness of the film, and the lubrication during processing, can greatly reduce the film surface dynamic and static friction coefficient, make the film surface smoother. At the same time, SILIMER series masterbatch has a special structure with good compatibility with the matrix resin, no precipitation, no sticky, and no effect on the transparency of film. It is widely used in the production of PP films, PE films.

| Product name | Appearance | Anti-block agent | Carrier resin | Recommend Dosage(W/W) | Application scope |

| Super Slip Masterbatch SILIMER5065HB | White or off-white pellet | Synthetic silica | PP | 0.5~6% | PP |

| Super Slip Masterbatch SILIMER5064MB2 | white or light yellow pellet | Synthetic silica | PE | 0.5~6% | PE |

| Super Slip Masterbatch SILIMER5064MB1 | white or light yellow pellet | Synthetic silica | PE | 0.5~6% | PE |

| Slip Silicone Masterbatch SILIMER 5065A | white or light yellow pellet | PP | 0.5~6% | PP/PE | |

| Super Slip Masterbatch SILIMER5065 | white or light yellow pellet | Synthetic silica | PP | 0.5~6% | PP/PE |

| Super Slip Masterbatch SILIMER5064A | white or light yellow pellet | -- | PE | 0.5~6% | PP/PE |

| Super Slip Masterbatch SILIMER5064 | white or light yellow pellet | -- | PE | 0.5~6% | PP/PE |

| Super Slip Masterbatch SILIMER5063A | white or light yellow pellet | -- | PP | 0.5~6% | PP |

| Super Slip Masterbatch SILIMER5063 | white or light yellow pellet | -- | PP | 0.5~6% | PP |

| Super Slip Masterbatch SILIMER5062 | white or light yellow pellet | -- | LDPE | 0.5~6% | PE |

| Super Slip Masterbatch SILIMER 5064C | white pellet | Synthetic silica | PE | 0.5~6% | PE |

SF series Super Slip Masterbatch

SILIKE Super slip Anti-blocking masterbatch SF series is specially developed for Plastic film products . Using specially modified silicone polymer as the active ingredient, it overcomes the key defects of general slip agents, including the continuous precipitation of the smooth agent from the surface of the film, the smooth performance decreasing with time-going by and the rise of temperature with unpleasant odors etc. It has the advantages of slip and Anti-blocking, excellent slip performances against high-temperature, low COF and no precipitation. SF series Masterbatch is widely used in the production of BOPP films, CPP films, TPU, EVA film, casting film and extrusion coating.

| Product name | Appearance | Anti-block agent | Carrier resin | Recommend Dosage(W/W) | Application scope |

| Super Slip Masterbatch SF500E | White or off-white pellet | -- | PE | 0.5~5% | PE |

| Super Slip Masterbatch SF240 | White or off-white pellet | Spherical organic PMMA | PP | 2~12% | BOPP/CPP |

| Super Slip Masterbatch SF200 | White or off-white pellet | -- | PP | 2~12% | BOPP/CPP |

| Super Slip Masterbatch SF105H | White or off-white pellet | -- | PP | 0.5~5% | BOPP/CPP |

| Super Slip Masterbatch SF205 | white pellet | -- | PP | 2~10% | BOPP/CPP |

| Super Slip Masterbatch SF110 | White Pellet | -- | PP | 2~10% | BOPP/CPP |

| Super Slip Masterbatch SF105D | White Pellet | Spherical organic matter | PP | 2~10% | BOPP/CPP |

| Super Slip Masterbatch SF105B | White Pellet | Spherical aluminum silicate | PP | 2~10% | BOPP/CPP |

| Super Slip Masterbatch SF105A | White or off-white pellet | Synthetic silica | PP | 2~10% | BOPP/CPP |

| Super Slip Masterbatch SF105 | White Pellet | -- | PP | 5~10% | BOPP/CPP |

| Super Slip Masterbatch SF109 | White pellet | -- | TPU | 6~10% | TPU |

| Super Slip Masterbatch SF102 | White pellet | -- | EVA | 6~10% | EVA |

FA series anti-blocking masterbatch

SILIKE FA series product is a unique anti-blocking masterbatch, currently, we have 3 types of silica, aluminosilicate, PMMA ...eg. Suitable for films, BOPP films, CPP films, oriented flat film applications and other products compatible with polypropylene. It can significantly improve the anti-blocking & smoothness of the film surface. SILIKE FA series products have a special structure with good compatibi.

| Product name | Appearance | Anti-block agent | Carrier resin | Recommend Dosage(W/W) | Application scope |

| Anti-blocking Masterbatch FA111E6 | White or off-white pellet | Synthetic silica | PE | 2~5% | PE |

| Anti-blocking Masterbatch FA112R | White or off-white pellet | Spherical aluminum silicate | Co-polymer PP | 2~8% | BOPP/CPP |

Matt Effect Masterbatch

Matt Effect Masterbatch is an innovative additive developed by Silike, utilizing thermoplastic polyurethane (TPU) as its carrier. Compatible with both polyester-based and polyether-based TPU, this masterbatch is designed to improve the matte appearance, surface touch, durability, and anti-blocking properties of TPU film and its other final products.

This additive offers the convenience of direct incorporation during processing, eliminating the need for granulation, with no risk of precipitation even with long-term use.

Suitable for various industries, including film packaging, wire& cable jacketing manufacturing, automotive applications, and consumer goods.

| Product name | Appearance | Anti-block agent | Carrier resin | Recommend Dosage(W/W) | Application scope |

| Matt Effect Masterbatch 3135 | White Matt pellet | -- | TPU | 5~10% | TPU |

| Matt Effect Masterbatch 3235 | White Matt pellet | -- | TPU | 5~10% | TPU |

Slip and anti-block masterbatch for EVA film

This series is specially developed for EVA films. Using specially modified silicone polymer copolysiloxane as the active ingredient, it overcomes the key shortcomings of general slip additives: including that the slip agent will continue to precipitate from the film surface, and the slip performance will change over time and temperature. Increase and decrease, smell, friction coefficient changes, etc. It is widely used in the production of EVA blown film, cast film and extrusion coating, etc.

| Product name | Appearance | Anti-block agent | Carrier resin | Recommend Dosage(W/W) | Application scope |

| Super Slip Masterbatch SILIMER2514E | white pellet | Silicon dioxide | EVA | 4~8% | EVA |

Silicone hyperdispersants

This series of products is a modified silicone additive, suitable for common thermoplastic resin TPE, TPU and other thermoplastic elastomers. Appropriate addition can improve the compatibility of pigment/filling powder/functional powder with the resin system, and make the powder keep the stable dispersion with good processing lubricity and efficient dispersion performance, and can effectively improve the surface hand feel of the material. It also provide a synergistic flame retardant effect in the field of flame retardant.

| Product name | Appearance | Active content | Volatile | Bulk density(g/ml) | Recommend dosage |

| Silicone Hyperdispersants SILIMER 6600 | Transparent liquid | -- | ≤1 | -- | -- |

| Silicone hyperdispersants SILIMER 6200 | White/off-white pellet | -- | -- | -- | 1%~2.5% |

| Silicone hyperdispersants SILIMER 6150 | white/white-off power | 50% | <4% | 0.2~0.3 | 0.5~6% |

Silicone Powder

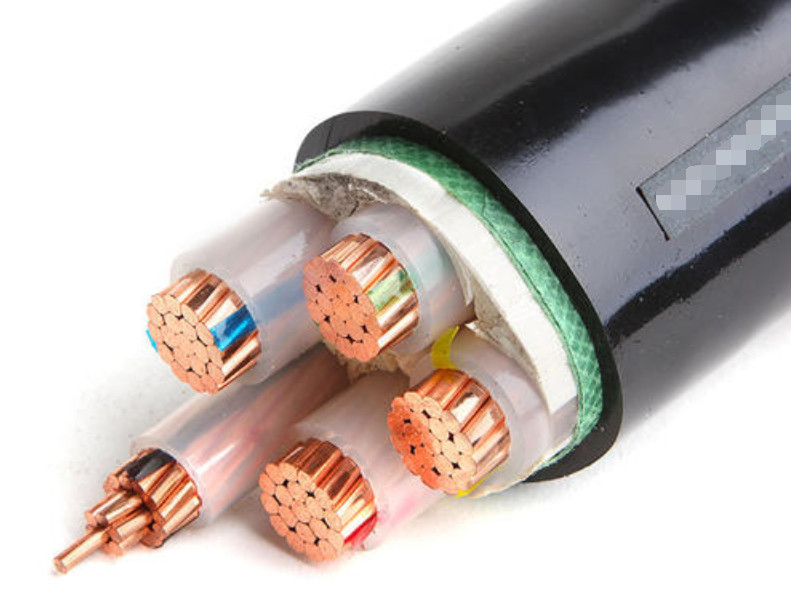

Silicone powder ( Siloxane powder ) LYSI series is a powder formulation which contains 55~70% UHMW Siloxane polymer dispersed in Silica . Suitable for various applications like wire&cable compounds, engineering plastics,color/ filler masterbatches...

Compare to conventional lower molecular weight Silicone / Siloxane additives,like Silicone oil, silicone fluids or other type processing aids, SILIKE Silicone powder is expected to give improved benefits on processing proopertise and modify the surface quality of final products, eg,. Less screw slippage , improved mold release, reduce die drool, a lower coefficient of friction, fewer paint and printing problems, and a broader range of performance capabilities.What’s more, it has synergistic flame retardancy effects when combined with aluminum phosphinate and other flame retardants.

| Product name | Appearance | Effective component | Active content | Carrier resin | Recommend Dosage(W/W) | Application scope |

| Silicone Powder LYSI-100A | White powder | Siloxane polymer | 55% | -- | 0.2~5% | PE,PP,EVA,PC,PA,PVC,ABS.... |

| Silicone Powder LYSI-100 | White powder | Siloxane polymer | 70% | -- | 0.2~5% | PE,PP,PC,PA,PVC,ABS.... |

| Silicone Powder LYSI-300C | White powder | Siloxane polymer | 65% | -- | 0.2~5% | PE,PP,PC,PA,PVC,ABS.... |

| Silicone Powder S201 | White powder | Siloxane polymer | 60% | -- | 0.2~5% | PE,PP,PC,PA,PVC,ABS.... |

Anti-scratch Masterbatch

SILIKE Anti-scratch masterbatch has an enhanced compatibility with the Polypropylene (CO-PP/HO-PP ) matrix -- Resulting in lower phase segregation of the final surface, which means it stays on the surface of the final plastics without any migration or exudation , reducing fogging , VOCS or Odors . Helps improve long-lasting anti-scratch properties of automotive interiors , by offering improvements in many aspects like Quality, Aging , Hand feel, Reduced dust buildup... etc. Suitable for variety of Automotive interior surface , such as : Door panels, Dashboards, Center Consoles, instrument panels...

| Product name | Appearance | Effective component | Active content | Carrier resin | Recommend Dosage(W/W) | Application scope |

| Anti-Scratch Masterbatch LYSI-413 |

White pellet | Siloxane polymer | 25% | PC | 2~5% | PC, PC/ABS |

| Anti-scratch Masterbatch LYSI-306H |

White pellet | Siloxane polymer | 50% | PP | 0.5~5% | PP,TPE,TPV... |

| Anti-scratch Masterbatch LYSI-301 |

White pellet | Siloxane polymer | 50% | PE | 0.5~5% | PE,TPE,TPV... |

| Anti-scratch Masterbatch LYSI-306 | White pellet | Siloxane polymer | 50% | PP | 0.5~5% | PP,TPE,TPV... |

| Anti-scratch Masterbatch LYSI-306C |

White pellet | Siloxane polymer | 50% | PP | 0.5~5% | PP,TPE,TPV... |

| Anti-scratch Masterbatch LYSI-405 |

White pellet | Siloxane polymer | 50% | ABS | 0.5~5% | ABS,PC/ABS, AS... |

Anti-abrasion Masterbatch

SILIKE Anti-abrasion masterbatches NM series is particularly developed for the footwear industry. Currently, we have 4 grades that are respectively suitable for EVA/PVC, TPR/TR, RUBBER and TPU shoe’s sole. A small addition of them can effectively improve the final item's abrasion resistance and decrease the abrasion value in the thermoplastics. Effective for DIN, ASTM, NBS, AKRON, SATRA, GB abrasion tests.

| Product name | Appearance | Effective component | Active content | Carrier resin | Recommend Dosage(W/W) | Application scope |

| Anti-abrasion Masterbatch LYSI-10 |

White pellet | Siloxane polymer | 50% | HIPS | 0.5~8% | TPR,TR... |

| Anti-abrasion Masterbatch NM-1Y |

White pellet | Siloxane polymer | 50% | SBS | 0.5~8% | TPR,TR... |

| Anti-abrasion Masterbatch NM-2T |

White pellet | Siloxane polymer | 50% | EVA | 0.5~8% | PVC, EVA |

| Anti-abrasion Masterbatch NM-3C |

White pellet | Siloxane polymer | 50% | RUBBER | 0.5~3% | Rubber |

| Anti-abrasion Masterbatch NM-6 |

White pellet | Siloxane polymer | 50% | TPU | 0.2~2% | TPU |

Anti-squeaking Masterbatch

Silike's anti-squeaking masterbatch is a special polysiloxane that provides excellent permanent anti-squeaking performance for PC / ABS parts at a lower cost. Since the anti-squeaking particles are incorporated during the mixing or injection molding process, there is no need for post-processing steps that slow down the production speed. It is important that SILIPLAS 2070 masterbatch maintain the mechanical properties of PC/ABS alloy-including its typical impact resistance. By expanding design freedom, this novel technology can benefit automotive OEMs and all walks of life. In the past, due to post-processing, complex part design became difficult or impossible to achieve complete post-processing coverage. In contrast, silicone additives do not need to modify the design to optimize their anti-squeaking performance. Silike's SILIPLAS 2070 is the first product in the new series of anti-noise silicone additives, which may be suitable for automobiles, transportation, consumer, construction and home appliances.

| Product name | Appearance | Effective component | Active content | Carrier resin | Recommend Dosage(W/W) | Application scope |

| Anti-squeak MasterbatchSILIPLAS 2073 | white pellet | Siloxane polymer | -- | -- | 3~8% | PC/ABS |

| Anti-squeak Masterbatch SILIPLAS 2070 |

White pellet | Siloxane polymer | -- | -- | 0.5~5% | ABS,PC/ABS |

Additive Masterbatch For WPC

SILIKE WPL 20 is a solid pellet contain UHMW Silicone copolymer dispersed in HDPE , it is particularly designed for Wood-plastic composites. A small dosage of it can significantly improve the processing properties and surface quality, including reducing the COF , lower extruder torque, higher extrusion-line speed, durable scratch & abrasion resistance and excellent surface finish with a good hand feel. Suitable for HDPE, PP, PVC .. wood plastic composites.

| Product name | Appearance | Effective component | Active content | Carrier resin | Recommend Dosage(W/W) | Application scope |

| WPC Lubricant SILIMER 5407B | Yellow or yellow-off powder | Siloxane polymer | -- | -- | 2%~3.5% | Wood plastics |

| Additive Masterbatch SILIMER 5400 | White or off-white pellet | Siloxane polymer | -- | -- | 1~2.5% | Wood plastics |

| Additive Masterbatch SILIMER 5322 | White or off-white pellet | Siloxane polymer | -- | -- | 1~5% | Wood plastics |

| Additive Masterbatch SILIMER 5320 |

white-off white pellet | Siloxane polymer | -- | -- | 0.5~5% | Wood plastics |

| Additive Masterbatch WPL20 |

White pellet | Siloxane polymer | -- | HDPE | 0.5~5% | Wood plastics |

Copolysiloxane Additives and Modifiers

The SILIMER Series of silicone wax products, developed by Chengdu Silike Technology Co., Ltd., are newly engineered Copolysiloxane Additives and Modifiers. These modified silicone wax products contain both silicone chains and active functional groups in their molecular structure, making them highly effective in the processing of plastics and elastomers.

Compared to ultra-high molecular weight silicone additives, these modified silicone wax products, have a lower molecular weight, allowing for easier migration without surface precipitation in plastics and elastomers. due to the active functional groups in the molecules that can play an anchoring role in the plastic and elastomer.

SILIKE Silicone wax SILIMER Series Copolysiloxane Additives and Modifiers can benefit the improvement of processing and modify surface properties of PE, PP, PET, PC, PE, ABS, PS, PMMA, PC/ABS, TPE, TPU, TPV, etc. which achieves the desired performance with a small dosage.

Additionally, the silicone wax SILIMER Series of Copolysiloxane Additives and Modifiers provide innovative solutions for improving the processability and surface properties of other polymers, including those used in coatings and paints.

| Product name | Appearance | Effective component | Active content | Recommend Dosage(W/W) | Application scope | Volatiles %(105℃×2h) |

| Silicone Wax SILIMER 5133 | Colorless Liquid | Silicone Wax | -- | 0.5~ 3% | -- | -- |

| Silicone Wax SILIMER 5140 | White pellet | Silicone wax | -- | 0.3~1% | PE, PP, PVC, PMMA, PC, PBT, PA, PC/ABS | ≤ 0.5 |

| Silicone Wax SILIMER 5060 | paste | Silicone wax | -- | 0.3~1% | PE, PP, PVC | ≤ 0.5 |

| Silicone Wax SILIMER 5150 | Milky yellow or light yellow pellet | Silicone Wax | -- | 0.3~1% | PE, PP, PVC, PET, ABS | ≤ 0.5 |

| Silicone Wax SILIMER 5063 | white or light yellow pellet | Silicone Wax | -- | 0.5~5% | PE , PP film | -- |

| Silicone wax SILIMER 5050 | paste | Silicone wax | -- | 0.3~1% | PE, PP, PVC, PBT, PET, ABS, PC | ≤ 0.5 |

| Silicone Wax SILIMER 5235 | White pellet | Silicone wax | -- | 0.3~1% | PC, PBT, PET, PC/ABS | ≤ 0.5 |

Silicone Additive for Biodegradable Materials

This series of products are specially researched and developed for biodegradable materials, applicable to PLA, PCL, PBAT and other biodegradable materials, which can play the role of lubrication when added in appropriate amount, improve the processing performance of the materials, improve the dispersion of the powder components, and also alleviate the odour generated during the processing of the materials, and effectively maintain the mechanical properties of the products without affecting the biodegradability of the products.

| Product name | Appearance | Recommend Dosage(W/W) | Application scope | MI(190℃,10KG) | Volatiles %(105℃×2h)< |

| SILIMER DP800 | White Pellet | 0.2~1 | PLA, PCL, PBAT... | 50~70 | ≤0.5 |

Silicone Gum

SILIKE SLK1123 is a high molecular weight raw gum with low vinyl content. It is insoluble in water, soluble in toluene and other organic solvents, suitable to be used as raw material gum for silicone additives, Color、vulcanizing agent and low hardness silicone products.

| Product name | Appearance | Molecular Weight*10⁴ | Vinyl link mole fraction % | Volatile content (150℃,3h)/%≤ |

| Silicone Gum SLK1101 | Water clear | 45~70 | -- | 1.5 |

| Silicone Gum SLK1123 |

Colorless transparent, no mechanical impurities | 85-100 | ≤0.01 | 1 |

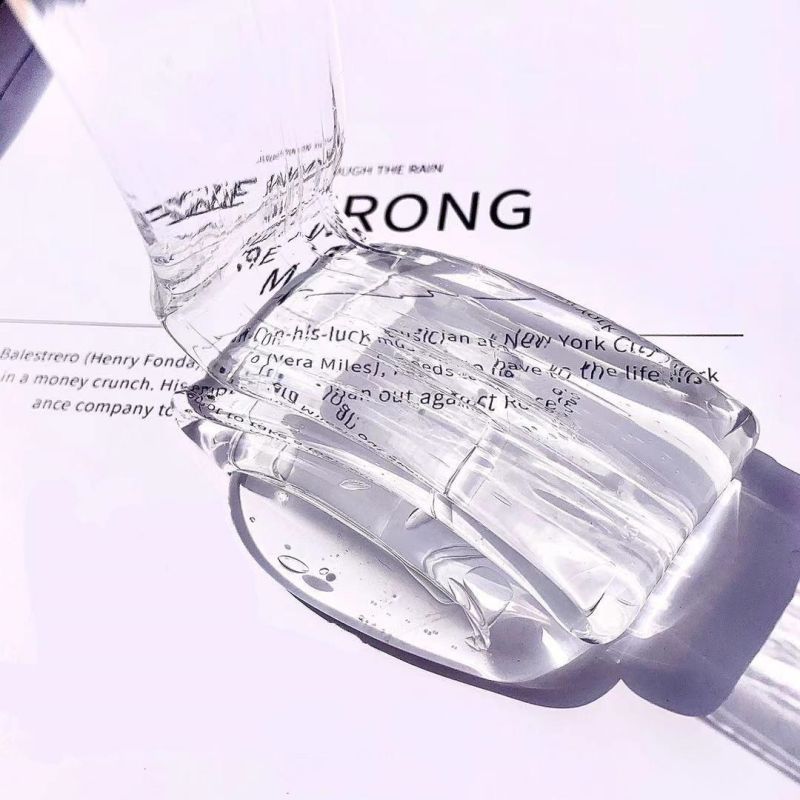

Silicone Fluid

SILIKE SLK series liquid silicone is a polydimethylsiloxane fluid with different viscosity from 100 to 1000 000 Cts. They are commonly used as a base fluid in personal care products, construction industries, cosmetics... besides, they can also be used as excellent lubricants for polymers and rubbers. Due to its chemical structure, SILIKE SLK series silicone oil is a clear, odorless and colorless liquid with excellent spreading and unique volatility characteristics.

| Product name | Appearance | Viscosity (25℃,) mm²/td> | Active content | Volatile content (150℃,3h)/%≤/td> |

| Silicone Fluid SLK-DM500 | Colorless transparent liquid without visible impurities | 100% | ||

| Silicone Fluid SLK-DM300 | Colorless transparent liquid without visible impurities | 100% | ||

| Silicone Fluid SLK-DM200 | Colorless transparent liquid without visible impurities | 100% | ||

| Silicone Fluid SLK-DM2000 | Colorless transparent liquid without visible impurities | 100% | ||

| Silicone Fluid SLK-DM12500 | Colorless transparent liquid without visible impurities | 100% | ||

| Silicone Fluid SLK 201-100 | Colorless and transparent | 100% |

SI-TPV 3100 Series

SILIKE SI-TPV is a dynamic vulcanizated thermoplastic Silicone-based elastomers which made by a special compatible technology, it helps silicone rubber dispersed in TPU evenly as a 2~3 micron droplets under microscope. This unique material provides a good combination of properties and benefits from thermoplastics and fully cross-linked silicone rubber. Suits for wearable device surface, artificial leather, Automotive, Phone bumper, Electronic devices accessories ( earbus, eg ), high-end TPE, TPU, TPV, Si-TPE,Si-TPU industries...

| Product name | Appearance | Elongation at break(%) | Tensile Strength(Mpa) | Hardness(Shore A) | Density(g/cm3) | MI(190℃,10KG) | Density(25℃,g/cm) |

| Si-TPV 3100-55A | White pellet | 757 | 10.2 | 55A | 1.17 | 47 | 1.17 |

| Si-TPV 3100-65A | White pellet | 395 | 9.4 | 65A | 1.18 | 18 | 1.18 |

| Si-TPV 3100-75A | White pellet | 398 | 11 | 75A | 1.18 | 27 | 1.18 |

SI-TPV 3300 Series

SILIKE SI-TPV is a dynamic vulcanizated thermoplastic Silicone-based elastomers which made by a special compatible technology, it helps silicone rubber dispersed in TPU evenly as a 2~3 micron droplets under microscope. This unique material provides a good combination of properties and benefits from thermoplastics and fully cross-linked silicone rubber. Suits for wearable device surface, artificial leather, Automotive, Phone bumper, Electronic devices accessories ( earbus, eg ), high-end TPE, TPU, TPV, Si-TPE,Si-TPU industries...

| Product name | Appearance | Elongation at break(%) | Tensile Strength(Mpa) | Hardness(Shore A) | Density(g/cm3) | MI(190℃,10KG) | Density(25℃,g/cm) |

| Si-TPV 3300-85A | White pellet | 515 | 9.19 | 85A | 1.2 | 37 | 1.2 |

| Si-TPV 3300-75A | White pellet | 334 | 8.2 | 75A | 1.22 | 19 | 1.22 |

| Si-TPV 3300-65A | White pellet | 386 | 10.82 | 65A | 1.22 | 29 | 1.22 |