China Supplier Siloxane Masterbatch used as Abrasion-resistant agents

Along with the “Client-Oriented” business philosophy, a rigorous good quality management method, state-of-the-art producing devices as well as a potent R&D workforce, we always supply high quality products and solutions, outstanding products and services and aggressive costs for China Supplier Siloxane Masterbatch used as Abrasion-resistant agents, Our organization quickly grew in size and status because of its absolute dedication to top quality manufacturing, higher value of merchandise and excellent customer assistance.

Along with the “Client-Oriented” business philosophy, a rigorous good quality management method, state-of-the-art producing devices as well as a potent R&D workforce, we always supply high quality products and solutions, outstanding products and services and aggressive costs for China Silicone additive, silicone masterbatch used as Abrasion-resistant agents, Siloxane additive, So We also continuously function. we, focuse on high quality, and are conscious of the importance of environmental protection, most of the merchandise are pollution-free, environmentally friendly products and solutions, reuse on the solution. We have Updated our catalog, which introduces our organization. n detail and covers the primary products we deliver at present, You may also visit our web-site, which involves our most recent product line. We look forward to reactivating our company connection.

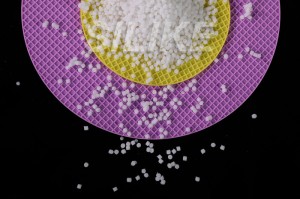

Anti-abrasion masterbatch NM-3C is a pelletized formulation with 50% active ingredient dispersed in rubber . It’s particularly developed for rubber shoe’s sole compounds, helps to improving the final items abrasion resistance and decrease the abrasion value in the thermoplastics .

Compare to conventional lower molecular weight Silicone / Siloxane additives,like Silicone oil, silicone fluids or other type abrasion additives, SILIKE Anti-abrasion Masterbatch NM-3C is expected to give a much better abrasion resistance property without any influence on hardness and color.

|

Grade |

NM-3C |

|

Appearance |

White pellet |

|

active ingredients content % |

50 |

|

Carrier |

rubber |

|

Melt index ( 190℃, 10.00KG ) g/10min |

5.10 ( typical value ) |

|

Dosage % (w/w) |

0.5~5% |

(1) Improved abrasion resistance with decreased abrasion value

(2) Impart the processing performance and final items appearance

(3) Eco-friendly

(4) No influence on hardness and color

(5) Effective for DIN, ASTM, NBS , AKRON, SATRA, GB abrasion tests

…..

Applicable for NR, NBR, EPDM, CR, BR, SBR, IR, HR, CSM, etc.

|

Basic formula |

NR/NBR | 40 |

+NM-3C |

0 |

2% |

4% |

6% |

| Engine oil | 5 |

DIN value |

170 |

139 |

129 |

117 |

|

| CB | 50 |

Mix NM-3C with rubber into internal mixer during the temperature rising mixture process, to evenly mix. The output temperature should be above 100 ℃. NM-3C is recommend to be used with Si-69.

When added to rubber at 0.2 to 1% , improved processing and flow of the resin is expected, including better mold filling, less extruder torque, internal lubricants, mold release and faster throughput; At a higher addition level , 2~10%, improved surface properties are expected, including lubricity , slip, lower coefficient of friction and greater mar/scratch and abrasion resistance

25Kg / bag , craft paper bag

Transport as non-hazardous chemical. Store in a cool , well ventilated place .

Original characteristics remain intact for 24 months from the production date , if kept in recommend storage.

Chengdu Silike Technology Co., Ltd is a manufacturer and supplier of silicone material, who has dedicated to R&D of the combination of Silicone with thermoplastics for 20+ years, products including but not limited to Silicone masterbatch , Silicone powder, Anti-scratch masterbatch, Super-slip Masterbatch, Anti-abrasion masterbatch, Anti-Squeaking masterbatch, Silicone wax and Silicone-Thermoplastic Vulcanizate(Si-TPV), for more details and test data, please feel free to contact Ms.Amy Wang Email: amy.wang@silike.cnAnti-abrasion masterbatch is an organic plastic auxiliary agent made from special modified organo-siloxane polymers as the main component and many functional agents. silicone masterbatch used as an Abrasion-resistant agent, can decrease its friction coefficient and wear rate and improve abrasion performance.

Typical application: The addition of SILIKE NM-3C anti-wear additive into rubber (BR, SBR, NBR, EPDM, CR, IR, HR, CSM, NR) while manufacturing the sole of the footwear, could greatly improve the abrasion resistance of the sole, reduce wear value.

FREE SILICONE ADDITIVES AND Si-TPV SAMPLES MORE THAN 100 GRADES

Sample type

$0

- 50+

grades Silicone Masterbatch

- 10+

grades Silicone Powder

- 10+

grades Anti-scratch Masterbatch

- 10+

grades Anti-abrasion Masterbatch

- 10+

grades Si-TPV

- 8+

grades Silicone Wax