China Wholesale Non-Migrate Low Friction Masterbatch Suppliers – Anti-squeak Additive Masterbatch SILIPLAS2070 In Automotive Interior – Silike

China Wholesale Non-Migrate Low Friction Masterbatch Suppliers – Anti-squeak Additive Masterbatch SILIPLAS2070 In Automotive Interior – Silike Detail:

Description

Noise reduction is an urgent issue in the automotive industry. The noise, vibration and sound vibration (NVH) inside the cockpit is more prominent in ultra-quiet electric vehicles. We hope that the cabin becomes a paradise for leisure and entertainment. Self-driving cars need a quiet internal environment.

Many components used in car dashboards, center consoles and trim strips are made of polycarbonate/acrylonitrile-butadiene-styrene (PC/ABS) alloy. When two parts move relatively to each other (stick-slip effect), friction and vibration will cause these materials to produce noise. Traditional noise solutions include the secondary application of felt, paint or lubricant, and special noise-reducing resins. The first option is multi-process, low efficiency and anti-noise instability, while the second option is very expensive.

Silike’s anti-squaking masterbatch are a special polysiloxane that provides excellent permanent anti-squeaking performance for PC / ABS parts at a lower cost. Since the anti-squeaking particles are incorporated during the mixing or injection molding process, there is no need for post-processing steps that slow down the production speed. It is important that SILIPLAS 2070 masterbatch maintain the mechanical properties of PC/ABS alloy-including its typical impact resistance. By expanding design freedom, this novel technology can benefit automotive OEMs and all walks of life. In the past, due to post-processing, complex part design became difficult or impossible to achieve complete post-processing coverage. In contrast, silicone additives do not need to modify the design to optimize their anti-squeaking performance. Silike’s SILIPLAS 2070 is the first product in the new series of anti-noise silicone additives, which may be suitable for automobiles, transportation, consumer, construction and home appliances.

Features

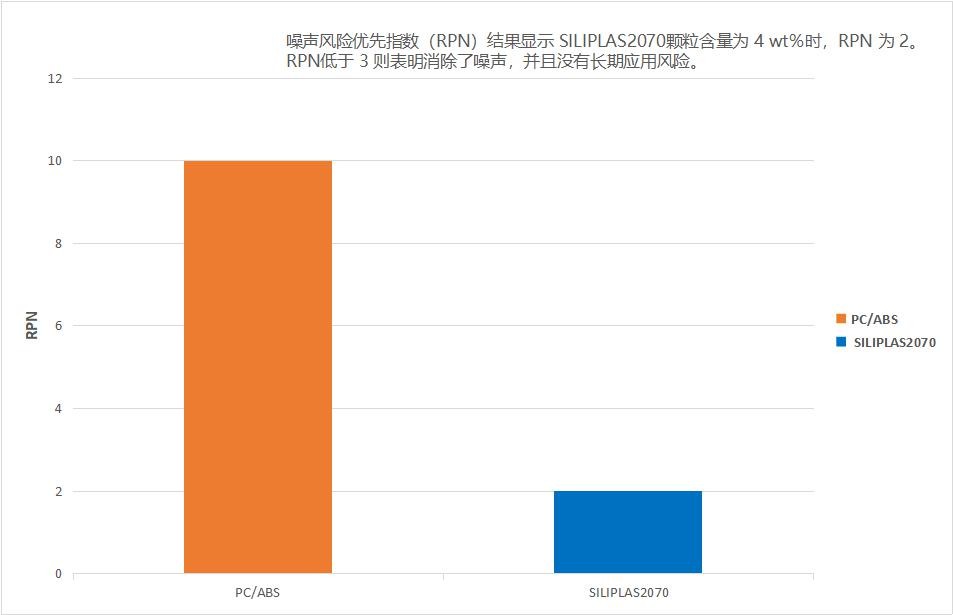

•Excellent noise reduction performance: RPN<3 (according to VDA 230-206)

• Reduce stick-slip

• Instant, long-lasting noise reduction characteristics

• Low coefficient of friction (COF)

• Minimal impact on the key mechanical properties of PC / ABS (impact, modulus, strength, elongation)

• Effective performance with low addition amount (4wt%)

• Easy to handle, free flowing particles

The noise risk priority index (RPN) results show that when the content of SILIPLAS 2070 is 4% (wt),the RPN is 2. RPN below 3 indicates that the noise is eliminated and there is no long-term application risk.

Fundamental Parameters

|

Test method |

Unit |

Typical value |

|

|

Appearance |

Visual inspection |

White pellet |

|

|

MI (190℃,10Kg) |

ISO1133 |

g/10min |

5 |

|

Density |

ISO1183 |

g/cm3 |

1.03-1.04 |

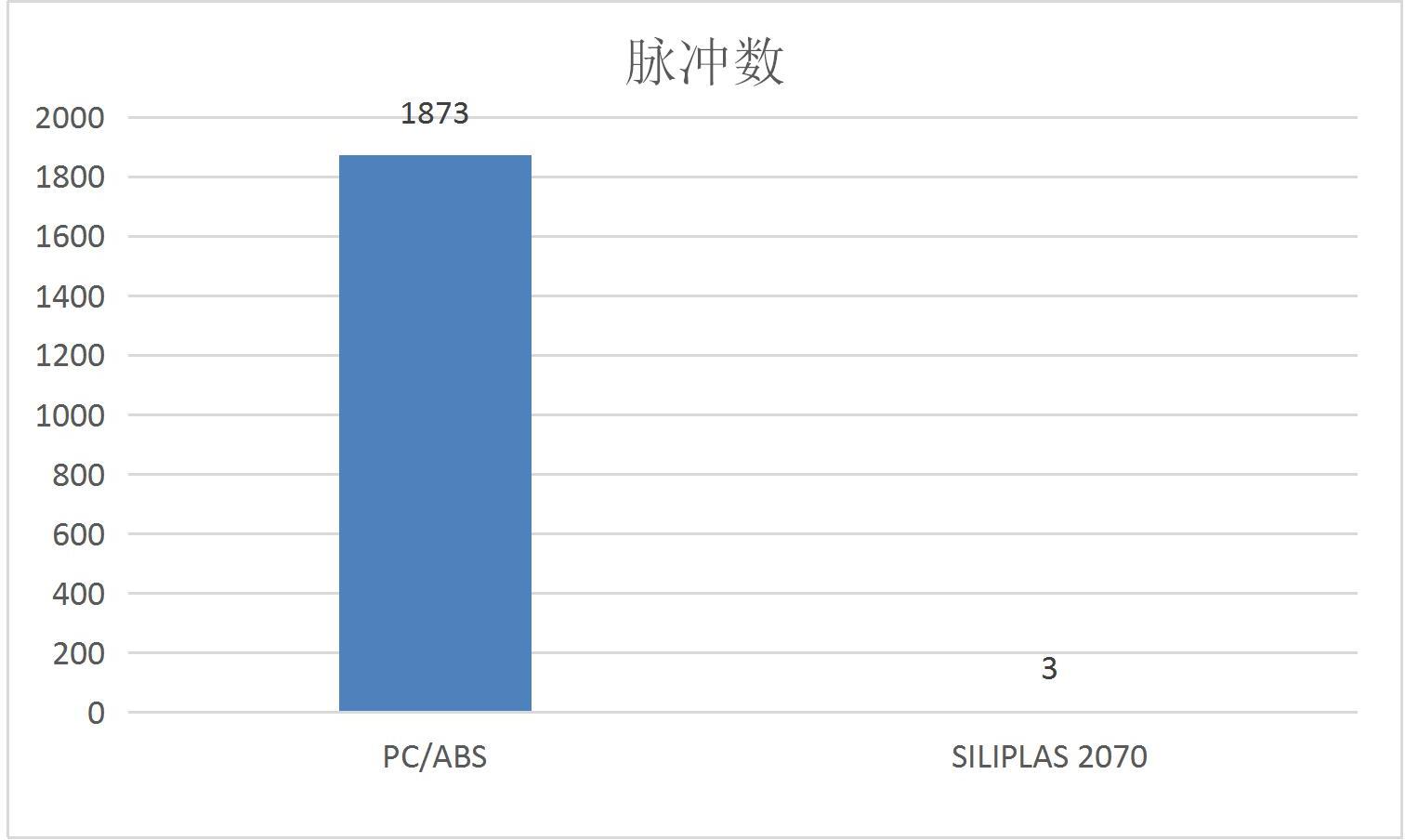

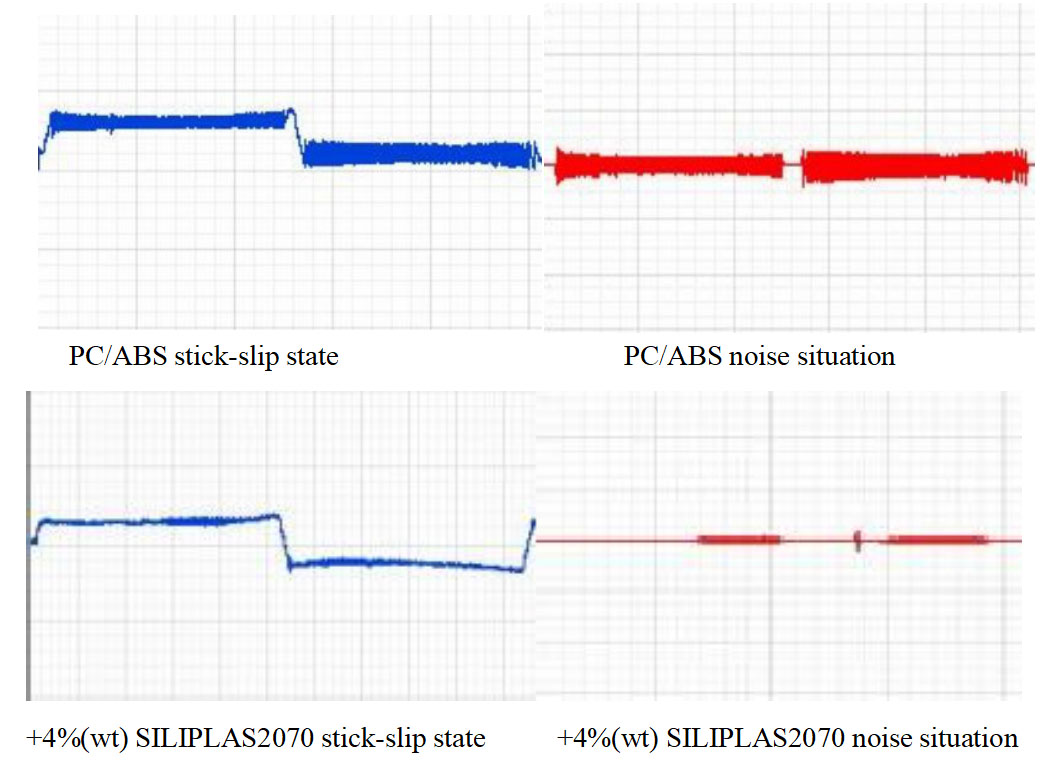

The graph of the pulse value change in the stick-slip test of PC/ABS after adding 4% SILIPLAS2070:

It can be seen that the stick-slip test pulse value of PC/ABS after adding 4% SILIPLAS2070 has dropped significantly, and the test conditions are V=1mm/s, F=10N.

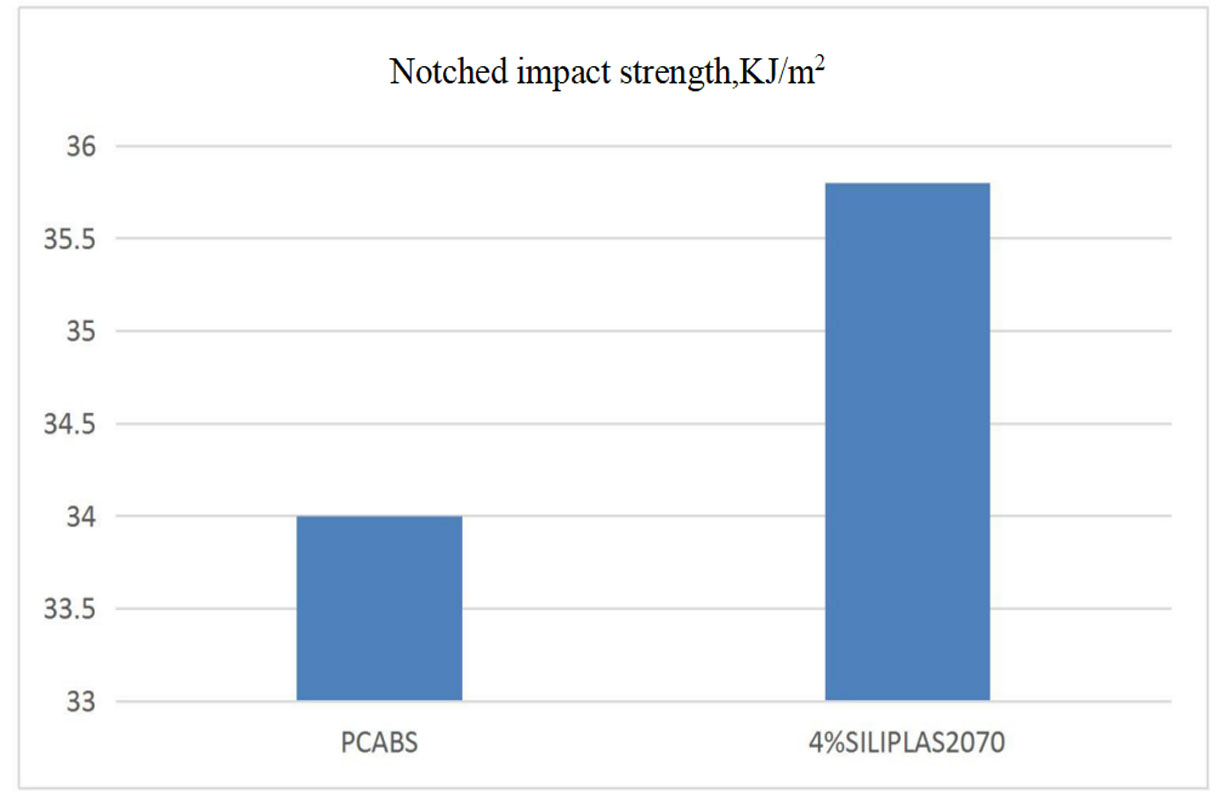

After adding 4% SILIPLAS2070, the impact strength will not be affected.

Benefits

• Minimize disturbing noise and vibration

• Provide stable COF during the service life of parts

• Optimize design freedom by implementing complex geometric shapes

• Simplify production by avoiding secondary operations

• Low dosage, improve cost control

Application field

• Automotive interior parts (trim, dashboard, console)

• Electrical parts (refrigerator tray) and trash can, washing machine, dishwasher)

• Building components (window frames),etc.

Goal customers

PC/ABS compounding plant and part forming plant

Usage and dosage

Added when the PC/ABS alloy is made, or after the PC/ABS alloy is made, and then melt-extrusion granulated, or it can be added directly and injection molded (under the premise of ensuring dispersion).

The recommended addition amount is 3-8%, the specific addition amount is obtained according to the experiment

Package

25Kg / bag , craft paper bag.

Storage

Transport as non-hazardous chemical. Store in a cool , well ventilated place .

Shelf life

Original characteristics remain intact for 24 months from the production date , if kept in recommend storage.

Product detail pictures:

Related Product Guide:

In order to best meet client's needs, all of our operations are strictly performed in line with our motto "High Quality, Competitive Price, Fast Service" for China Wholesale Non-Migrate Low Friction Masterbatch Suppliers – Anti-squeak Additive Masterbatch SILIPLAS2070 In Automotive Interior – Silike , The product will supply to all over the world, such as: Morocco, Florence, Algeria, Our company is an international supplier on this kind of merchandise. We offer an amazing selection of high-quality products. Our goal is to delight you with our distinctive collection of mindful products while providing value and excellent service. Our mission is simple: To provide the best products and service to our customers at the lowest prices possible.

FREE SILICONE ADDITIVES AND Si-TPV SAMPLES MORE THAN 100 GRADES

Sample type

$0

- 50+

grades Silicone Masterbatch

- 10+

grades Silicone Powder

- 10+

grades Anti-scratch Masterbatch

- 10+

grades Anti-abrasion Masterbatch

- 10+

grades Si-TPV

- 8+

grades Silicone Wax

Production management mechanism is completed, quality is guaranteed, high credibility and service let the cooperation is easy, perfect!