China wholesale Si-Tpv - TPO based Skin-friendly thermoplastic elastomer Si-TPV2150-55A – Silike

China wholesale Si-Tpv - TPO based Skin-friendly thermoplastic elastomer Si-TPV2150-55A – Silike Detail:

Description

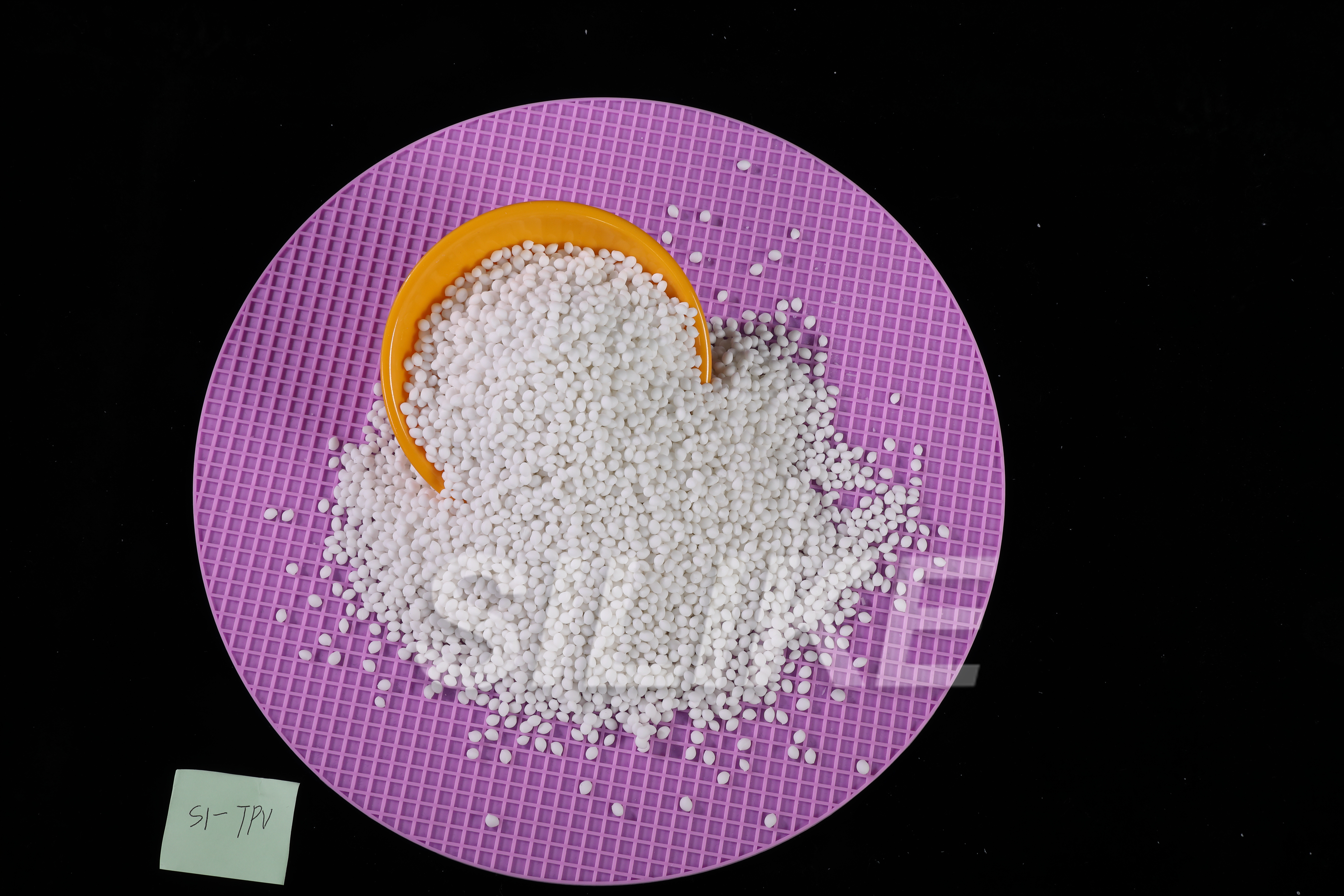

SILIKE Si-TPV® 2150-55A thermoplastic elastomer is a patented dynamic vulcanized thermoplastic silicone-based elastomer which made by a special compatible technology to help silicone rubber dispersed in TPO evenly as a 2~3 micron particles under microscope. Those unique materials combine the strength, toughness and abrasion resistance of any thermoplastic elastomer with desirable properties of silicone: softness, silky feel, UV light and chemicals resistance which can be recycled and reused in traditional manufacturing processes.

Si-TPV® 2150-55A can excellent bond to TPE and similar polar substrates like PP, PA, PE, PS, etc… It is a product developed for soft touch overmolding on wearable electronics, accessory cases for electronic devices, automotive, high-end TPE, TPE wire industries ……

Typical mechanical properties

| Test item | Property | Unit | Result |

| ISO 37 | Elongation at Break | % | 590 |

| ISO 37 | Tensile Streng | Mpa | 6.7 |

| ISO 48-4 | Shore A Hardness | Shore A | 55 |

| ISO1183 | Density | g/cm3 | 1.1 |

| ISO 34-1 | Tear Strength | kN/m | 31 |

| – | Modulus of Elasticity | Mpa | 4.32 |

| – | MI( 190℃,10KG) | g/10 min | 13 |

| – | Melt Temperature Optimum | ℃ | 220 |

| – | Mold Temperature Optimum | ℃ | 25 |

Characteristics

Compatibility SEBS, PP, PE, PS, PET, PC, PMMA, PA

Benefits

1. Provide the surface with Unique silky and skin-friendly touch, soft hand feeling with good mechanical properties.

2. Not contain plasticizer and softening oil, no bleeding / sticky risk, no odors.

3. UV stable and chemical resistance with excellent bonding to TPE and similar polar substrates.

4. Reduce dust adsorption, oil resistance and less pollute.

5. Easy to demould, and easy to handle.

6. Durable abrasion resistance & crush resistance & scratch resistance.

7. Excellent flexibility and kink resistance.

…..

How to use

Directly injection molding.

• Injection Molding Processing Guide

| Drying Time |

2–4 hrs |

| Drying Temperature |

60–80°C |

| Feed Zone Temperature |

180–190°C |

| Center Zone Temperature |

190–200°C |

| Front Zone Temperature |

200–220°C |

| Nozzle Temperature |

210–230°C |

| Melt Temperature |

220°C |

| Mold Temperature |

20–40°C |

| Injection Speed |

Med |

These process conditions may vary with individual equipment and processes.

• Secondary Processing

As a thermoplastic material, Si-TPV® material can be secondary processed for ordinary products.

• Injection Molding Pressure

The holding pressure largely depends on the geometry, thickness and gate location of the product. The holding pressure should be set to a low value at first, and then slowly increase until no related defects are seen in the injection molded product. Due to the elastic properties of the material, excessive holding pressure may cause serious deformation of the gate part of the product.

• Back pressure

It is recommended that the back pressure when the screw is retracted should be 0.7-1.4Mpa, which will not only ensure the uniformity of melt melting, but also ensure that the material is not severely degraded by shear. The recommended screw speed of Si-TPV® is 100-150rpm to ensure the complete melting and plasticization of the material without material degradation caused by shear heating.

Remark

1. Si-TPV elastomer products can be manufactured using standard thermoplastic manufacturing processes, including overmolding or co-molding with plastic substrates such as PP, PA.

2. The extremely silky feel of Si-TPV elastomer does not require additional processing or coating steps.

3. The process conditions may vary with individual equipment and processes.

4. A desiccant dehumidifying drying is recommended for all drying.

Package

25KG / bag , craft paper bag with a PE inner bag

Shelf life and storge

Transport as non-hazardous chemical. Store in a cool and well ventilated place.

Original characteristics remain intact for 12 months from the production date if kept in recommend storage.

Product detail pictures:

Related Product Guide:

Our commission would be to serve our customers and clientele with very best excellent and aggressive portable digital products for China wholesale Si-Tpv - TPO based Skin-friendly thermoplastic elastomer Si-TPV2150-55A – Silike , The product will supply to all over the world, such as: Milan, Norway, Pretoria, Now we have a dedicated and aggressive sales team, and many branches, catering to our main customers. We have been looking for long-term business partnerships, and ensure our suppliers that they will undoubtedly benefit in both short and long run.

FREE SILICONE ADDITIVES AND Si-TPV SAMPLES MORE THAN 100 GRADES

Sample type

$0

- 50+

grades Silicone Masterbatch

- 10+

grades Silicone Powder

- 10+

grades Anti-scratch Masterbatch

- 10+

grades Anti-abrasion Masterbatch

- 10+

grades Si-TPV

- 8+

grades Silicone Wax

In general, we are satisfied with all aspects, cheap, high-quality, fast delivery and good procuct style, we will have follow-up cooperation!