China Wholesale Thermoplastic Elastomers For Smart Watch Strips Factory – SILIPLAS2070(EN) – Silike

China Wholesale Thermoplastic Elastomers For Smart Watch Strips Factory – SILIPLAS2070(EN) – Silike Detail:

Description

Noise reduction is an urgent issue in the automotive industry. The noise, vibration and sound vibration (NVH) inside the cockpit is more prominent in ultra-quiet electric vehicles. We hope that the cabin becomes a paradise for leisure and entertainment. Self-driving cars need a quiet internal environment.

Many components used in car dashboards, center consoles and trim strips are made of polycarbonate/acrylonitrile-butadiene-styrene (PC/ABS) alloy. When two parts move relatively to each other (stick-slip effect), friction and vibration will cause these materials to produce noise. Traditional noise solutions include the secondary application of felt, paint or lubricant, and special noise-reducing resins. The first option is multi-process, low efficiency and anti-noise instability, while the second option is very expensive.

Silike’s anti-squaking masterbatch are a special polysiloxane that provides excellent permanent anti-squeaking performance for PC / ABS parts at a lower cost. Since the anti-squeaking particles are incorporated during the mixing or injection molding process, there is no need for post-processing steps that slow down the production speed. It is important that SILIPLAS 2070 masterbatch maintain the mechanical properties of PC/ABS alloy-including its typical impact resistance. By expanding design freedom, this novel technology can benefit automotive OEMs and all walks of life. In the past, due to post-processing, complex part design became difficult or impossible to achieve complete post-processing coverage. In contrast, silicone additives do not need to modify the design to optimize their anti-squeaking performance. Silike’s SILIPLAS 2070 is the first product in the new series of anti-noise silicone additives, which may be suitable for automobiles, transportation, consumer, construction and home appliances.

Features

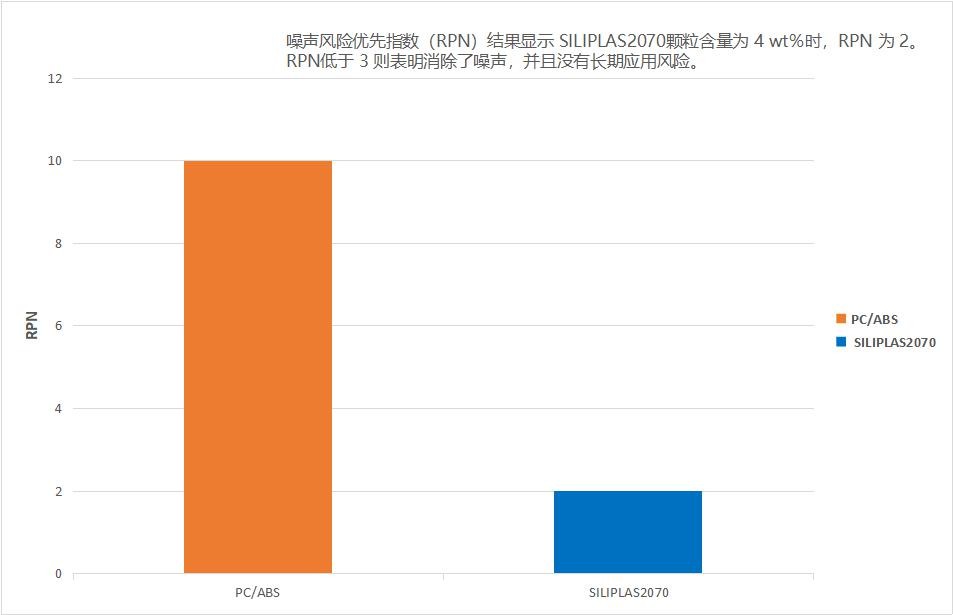

•Excellent noise reduction performance: RPN<3 (according to VDA 230-206)

• Reduce stick-slip

• Instant, long-lasting noise reduction characteristics

• Low coefficient of friction (COF)

• Minimal impact on the key mechanical properties of PC / ABS (impact, modulus, strength, elongation)

• Effective performance with low addition amount (4wt%)

• Easy to handle, free flowing particles

The noise risk priority index (RPN) results show that when the content of SILIPLAS 2070 is 4% (wt),the RPN is 2. RPN below 3 indicates that the noise is eliminated and there is no long-term application risk.

Fundamental Parameters

|

Test method |

Unit |

Typical value |

|

|

Appearance |

Visual inspection |

White pellet |

|

|

MI (190℃,10Kg) |

ISO1133 |

g/10min |

5 |

|

Density |

ISO1183 |

g/cm3 |

1.03-1.04 |

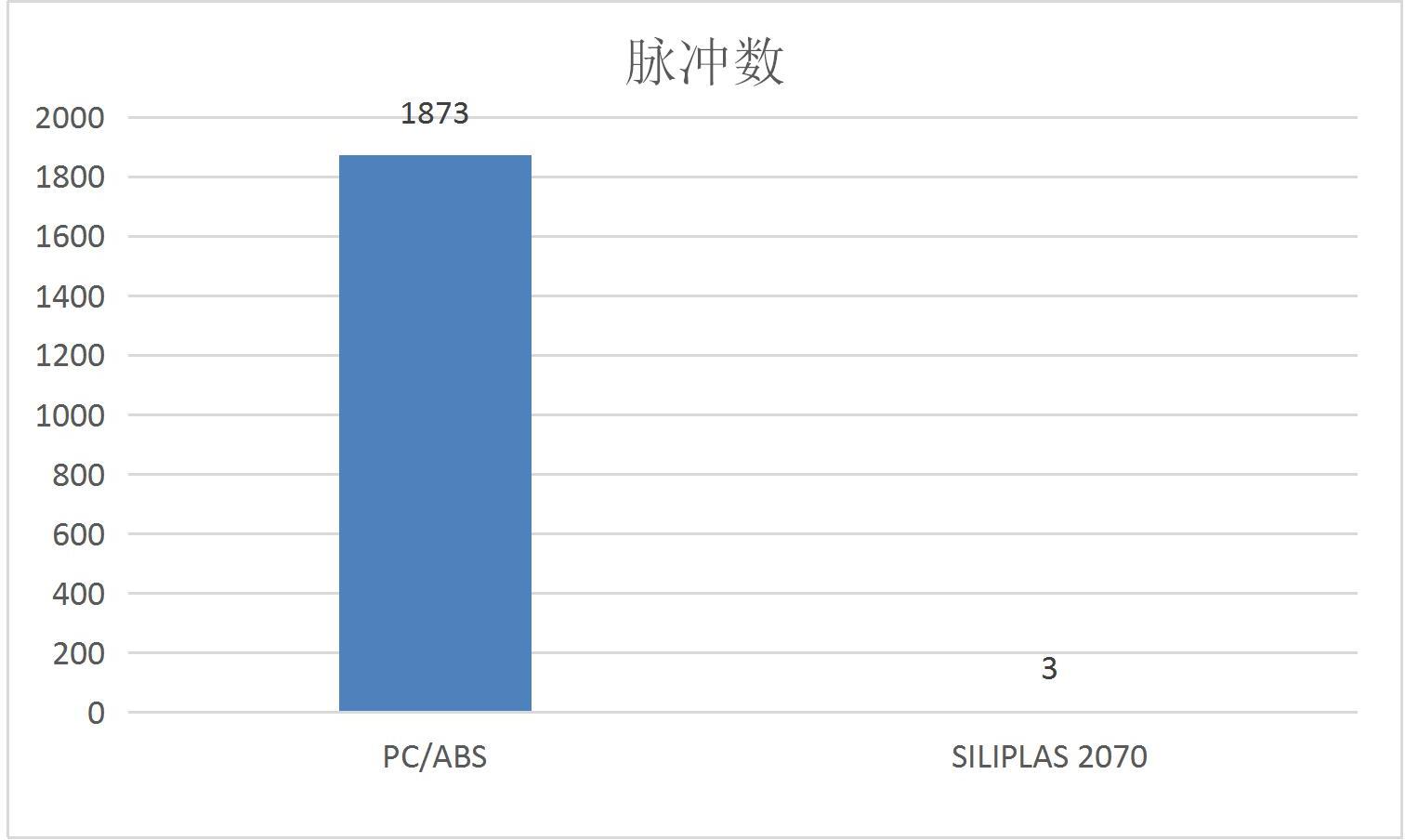

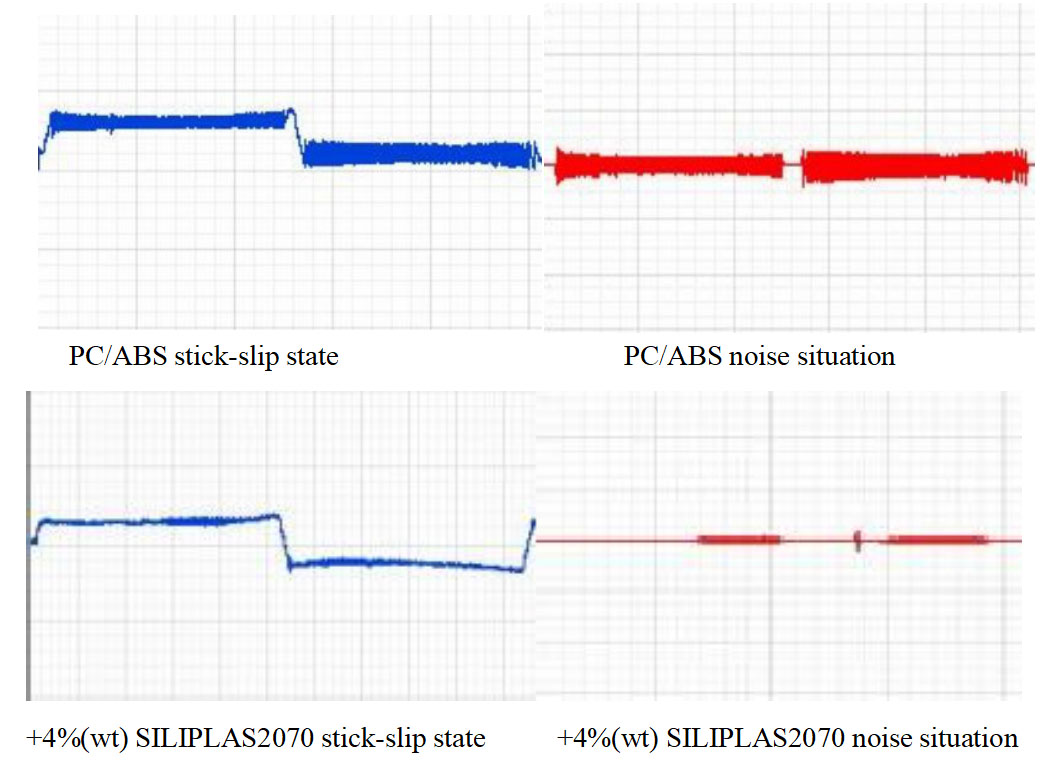

The graph of the pulse value change in the stick-slip test of PC/ABS after adding 4% SILIPLAS2070:

It can be seen that the stick-slip test pulse value of PC/ABS after adding 4% SILIPLAS2070 has dropped significantly, and the test conditions are V=1mm/s, F=10N.

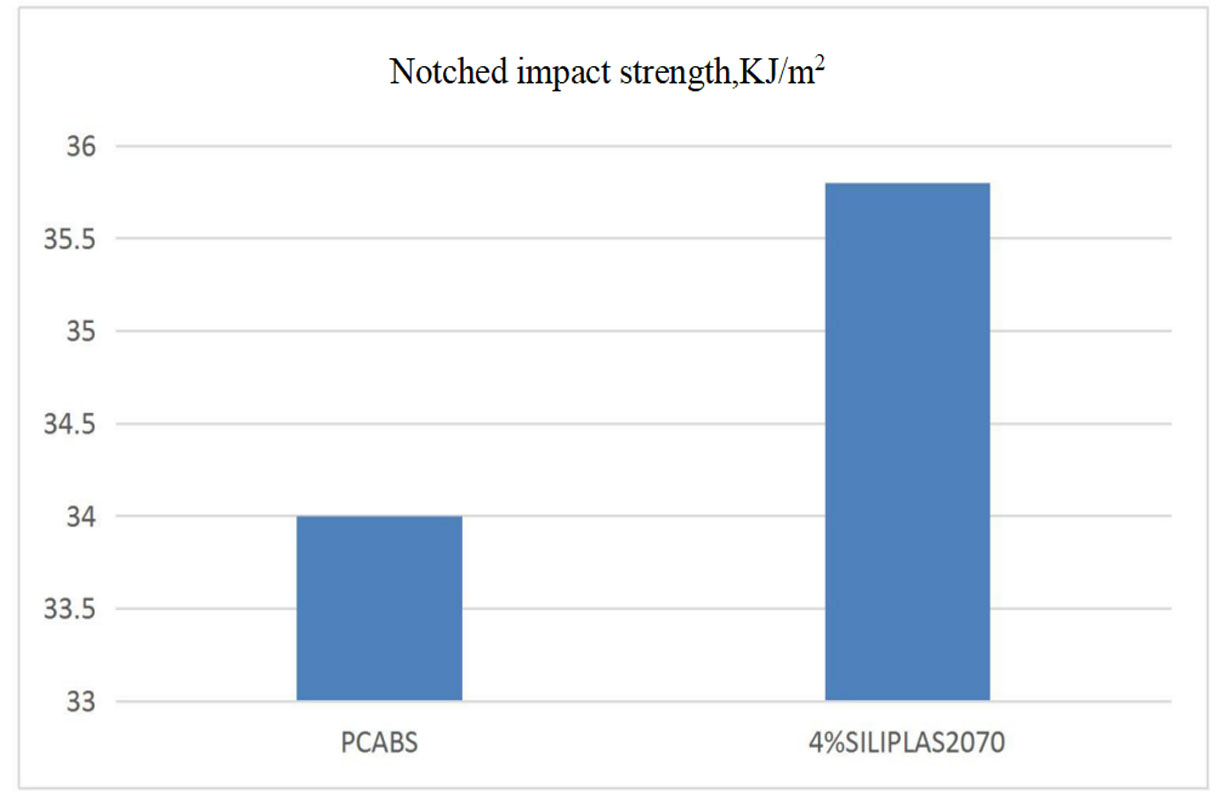

After adding 4% SILIPLAS2070, the impact strength will not be affected.

Benefits

• Minimize disturbing noise and vibration

• Provide stable COF during the service life of parts

• Optimize design freedom by implementing complex geometric shapes

• Simplify production by avoiding secondary operations

• Low dosage, improve cost control

Application field

• Automotive interior parts (trim, dashboard, console)

• Electrical parts (refrigerator tray) and trash can, washing machine, dishwasher)

• Building components (window frames),etc.

Goal customers

PC/ABS compounding plant and part forming plant

Usage and dosage

Added when the PC/ABS alloy is made, or after the PC/ABS alloy is made, and then melt-extrusion granulated, or it can be added directly and injection molded (under the premise of ensuring dispersion).

The recommended addition amount is 3-8%, the specific addition amount is obtained according to the experiment

Package

25Kg / bag , craft paper bag.

Storage

Transport as non-hazardous chemical. Store in a cool , well ventilated place .

Shelf life

Original characteristics remain intact for 24 months from the production date , if kept in recommend storage.

Product detail pictures:

Related Product Guide:

With dependable high quality approach, great reputation and excellent customer support, the series of products and solutions produced by our firm are exported to lots of countries and regions for China Wholesale Thermoplastic Elastomers For Smart Watch Strips Factory – SILIPLAS2070(EN) – Silike , The product will supply to all over the world, such as: Washington, Algeria, Yemen, Thus far, our item associated with printer dtg a4 may be shown in most foreign nations as well as urban centers, which are sought after simply by targeted traffic. We all highly imagine that now we have the full capacity to present you with contented merchandise. Desire to collect requests of your stuff and produce the long-term co-operation partnership. We very seriously promise:Csame top quality, better price; exact same selling price, higher quality.

FREE SILICONE ADDITIVES AND Si-TPV SAMPLES MORE THAN 100 GRADES

Sample type

$0

- 50+

grades Silicone Masterbatch

- 10+

grades Silicone Powder

- 10+

grades Anti-scratch Masterbatch

- 10+

grades Anti-abrasion Masterbatch

- 10+

grades Si-TPV

- 8+

grades Silicone Wax

A good manufacturers, we have cooperated twice, good quality and good service attitude.