Engineering Plastics Additives Manufacturers From China

Engineering Plastics Additives Manufacturers From China,

Engineering Plastics Additives, Internal lubricant, Plastic Injection Mold Release Agents, release Agent, scratch-resistant and wear-resistance agent,

Description

SILIMER 5140 is a polyester modified silicone additive with excellent thermal stability. It is used in thermoplastic products such as PE, PP, PVC, PMMA, PC, PBT, PA, PC/ABS, etc. It could Obviously improve the scratch-resistant and wear-resistant surface properties of products, improve the lubricity and mold release of the material processing process so that the product property is better. At the same time, SILIMER 5140 has a special structure with good compatibility with the matrix resin, no precipitation, no effect on the appearance and surface treatment of products.

Product Specifications

| Grade | SILIMER 5140 |

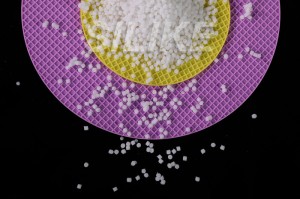

| Appearance | White pellet |

| Concentration | 100% |

| Melt index (℃) | 50-70 |

| Volatiles %(105℃×2h) | ≤ 0.5 |

Application advantages

1) Improve scratch resistance and wear resistance;

2) Reduce surface friction coefficient, improve surface smoothness;

3) Make the product have good mold release and lubricity, improve processing efficiency.

Typical applications:

Scratch-resistant, lubricated, mold release in PE, PP, PVC, PMMA, PC, PBT, PA, PC/ABS and other plastics,etc;

Scratch-resistant, lubricated in thermoplastic elastomers such as TPE, TPU.

How to use

Addition levels between 0.3~1.0% are suggested. It can be used in classical melt blending process like Single /Twin screw extruders, injection molding and side feed. A physical blend with virgin polymer pellets is recommended.

Transportation & Storage

This product could be transported as non-hazardous chemical. It is recommended to be stored in a dry and cool area with temperature below 40 ° C to avoid agglomeration. The package must be well sealed after opening to prevent products from being affected by moisture.

Package & Shelf life

The standard packaging is a PE inner bag and outer carton with net weight of 25kg. Original characteristics remain intact for 12 months from the date of production if kept with recommended storage method.Consistency of surface finish, optimization of cycle time, and reduction of post-mold operations prior to painting or gluing are all important factors in plastics processing operations!

Plastic Injection Mold Release Agents may have more than one function. Some stay on the plastic surface and lubricate the plastic. The advantages of silicone-based release agents compared to those without silicone, they offer excellent release properties and are usually advantageous for the manufacture of products with long cycle times. Silike Technology has been committed to offering all kinds of polymer additives for plastics and rubber manufacturing, SILIKE Silicone additive can be used as an excellent internal lubricant, release agent, and scratch-resistant and wear-resistance agent for Engineering Plastics processing and surface quality improvement

FREE SILICONE ADDITIVES AND Si-TPV SAMPLES MORE THAN 100 GRADES

Sample type

$0

- 50+

grades Silicone Masterbatch

- 10+

grades Silicone Powder

- 10+

grades Anti-scratch Masterbatch

- 10+

grades Anti-abrasion Masterbatch

- 10+

grades Si-TPV

- 8+

grades Silicone Wax

.jpg)

-300x199.jpg)

-300x199.jpg)

-300x199.jpg)

-300x199.jpg)