Lubricant Additive (Processing Aids) For WPC SILIMER 5400

Description

This lubricant additive is specially developed for the processing and production of PE and PP WPC (wood plastic materials) such as WPC decking, WPC fence, and other WPC composites, etc. The core component of this lubricant solution for WPC is modified polysiloxane, containing polar active groups, excellent compatibility with resin and wood powder, in the process of processing and production can improve the dispersion of wood powder, does not affect the compatibility effect of compatibilizers in the system, can effectively improve the mechanical properties of the product. This release agent for WPC composites is better than WPC wax or WPC stearate additives and cost-effective, excellent lubrication, can improve the matrix resin processing properties, but also can make the product smoother, give your wood plastic composites a new shape.

Product Specifications

|

Grade |

SILIMER 5400 |

|

Appearance |

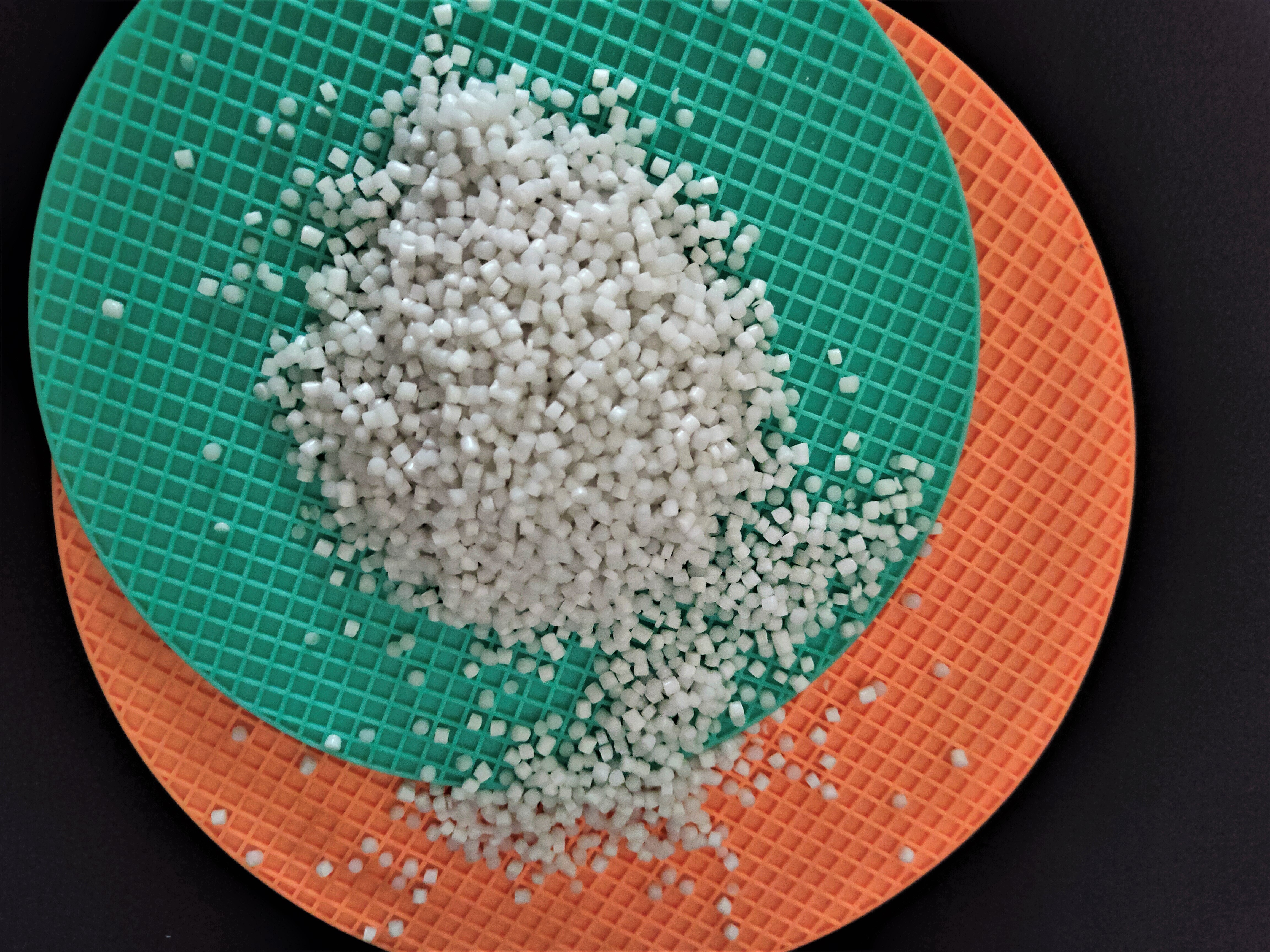

white or off-white pellet |

|

Melting point(°C) |

45~65 |

|

Viscosity( mPa.S) |

190 (100°C) |

|

Dosage%(W/W) |

1~2.5% |

| Precipitation resistance capability | Boiling at 100℃ for 48 hours |

| Decomposition temperature (°C) | ≥300 |

Advantages of WPC lubricant additives

1. Improve processing, reduce extruder torque, improve filler dispersion;

2. Internal&external lubricant for WPC, reduce energy consumption and increase production efficiency;

3. Good compatibility with wood powder, does not affect the forces between the molecules of the wood plastic composite and maintains the mechanical properties of the substrate itself;

4. Reduce amount of compatibilizer, reduce product defects, improve appearance of wood plastic products;

5. No precipitation after boiling test, keep long-term smoothness.

How to use

Addition levels between 1~2.5% are suggested. It can be used in classical melt blending process like Single /Twin screw extruders, injection molding and side feed. A physical blend with virgin polymer pellets is recommended.

Transportation & Storage

This masterbatch for WPC processing could be transported as non-hazardous chemical. It is recommended to be stored in a dry and cool area with a storage temperature below 40 ° C to avoid agglomeration. The package must be well sealed after each use to prevent the product from being affected by moisture.

Package & Shelf life

The standard packaging is a craft paper bag with PE inner bag with net weight of 25kg. Original characteristics remain intact for 24 months from the production date if kept in recommend storage.

FREE SILICONE ADDITIVES AND Si-TPV SAMPLES MORE THAN 100 GRADES

Sample type

$0

- 50+

grades Silicone Masterbatch

- 10+

grades Silicone Powder

- 10+

grades Anti-scratch Masterbatch

- 10+

grades Anti-abrasion Masterbatch

- 10+

grades Si-TPV

- 8+

grades Silicone Wax