Lubricant masterbatch SILIMER 5320 Enhanced Sustainability of WPC

Description

SILIMER 5320 lubricant masterbatch is newly developed silicone copolymer with special groups which has an excellent compatibility with wood powder, a small addition of it (w/w) can improve the quality of wood plastic composites in an efficient manner while reducing production costs and no need secondary treatment.

Product Specifications

|

Grade |

SILIMER 5320 |

|

Appearance |

White-off white pellet |

|

Density |

0.9253 g/cm3 |

|

MFR (190℃ /2.16KG) |

220-250g/10min |

|

Volatiles % (100℃*2h) |

0.465% |

|

Recommend dosage |

0.5-5% |

Benefits

1) Improve processing , reduce extruder torque

2) Reduce internal and external friction, reduce energy consumption and increase production capacity

3) Highly improve mechanical properties

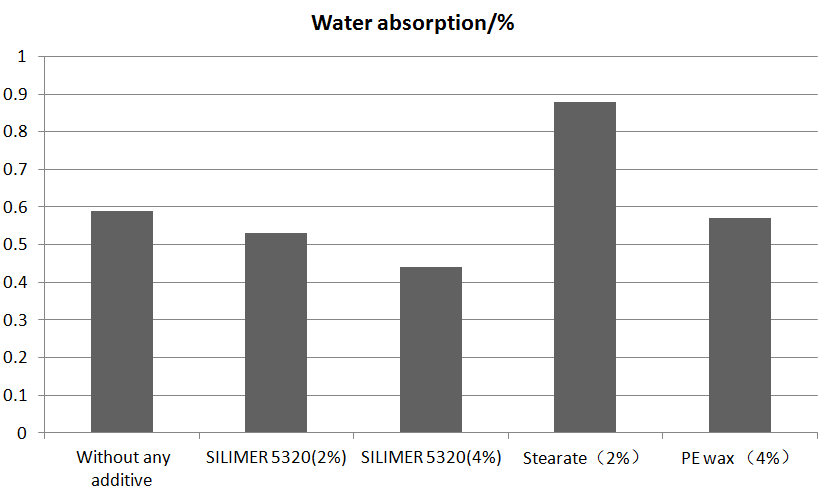

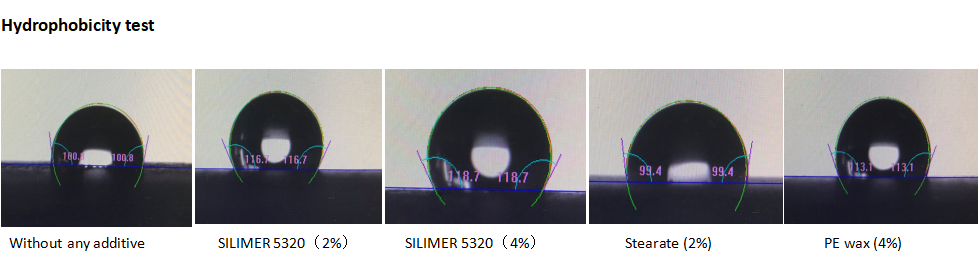

4) Good hydrophobic properties

5) No blooming, long-term smoothness

.......

Test data ( Basic recipe: 60% wood powder + 4% coupling agent + 36% HDPE)

How to use

Addition levels between 0.5~5.0% are suggested. It can be used in classical melt blending process like Single /Twin screw extruders, injection molding and side feed. A physical blend with virgin polymer pellets is recommended .

Transportation & Storage

This product could be transported as non-hazardous chemical. It is recommended to be stored in a dry and cool area with a storage temperature below 50 ° C to avoid agglomeration. The package must be well sealed after each use to prevent the product from being affected by moisture.

Package & Shelf life

The standard packaging is a craft paper bag with PE inner bag with net weight of 25kg . Original characteristics remain intact for 12 months from the production date if kept in recommend storage.

Marks: The information contained herein is offered in good faith and is believed to be accurate. However, because conditions and methods of use of our products are beyond our control, this information cannot be understood as a commitment of this product. The raw materials and its composition of this product will not be introduced here because patented technology is involved.

FREE SILICONE ADDITIVES AND Si-TPV SAMPLES MORE THAN 100 GRADES

Sample type

$0

- 50+

grades Silicone Masterbatch

- 10+

grades Silicone Powder

- 10+

grades Anti-scratch Masterbatch

- 10+

grades Anti-abrasion Masterbatch

- 10+

grades Si-TPV

- 8+

grades Silicone Wax