Understanding the Problem: Powdering and Blooming in PE Films

If you’ve experienced powdering and blooming issues in your polyethylene (PE) films, you’re not alone. The presence of white powdery spots or waxy residues on the film’s surface may impact not only aesthetics but also crucial functions like printing quality and packaging integrity. Fortunately, this issue—often caused by additives migrating out of the film—can be effectively managed with the right strategies.

Why Do Additives “Migrate”? Let’s Explore the Causes

Slip additive migration is frequently influenced by the properties of certain materials rather than your processing techniques. Lubricants and slip agents such as stearamide or erucamide, which are commonly added to enhance the smoothness of PE films, may form weak physical bonds with the resin. Over time and with temperature fluctuations, these small molecules can migrate to the surface, leading to the appearance of powdery or waxy layers. This issue can become more significant in thicker films, particularly those over 60μm in thickness, and can be aggravated by high temperatures or equipment residues.

Consequences of Additive Migration: What to Watch Out For

Understanding the potential repercussions of additive migration can help you mitigate risks effectively:

1. Production Interruptions: Powder buildup can lead to jams or breakages in automatic packaging machines, causing costly downtime.

2. Printing and Lamination Challenges: A slick surface may hinder proper ink adhesion, resulting in subpar printing and weak bonding during lamination.

3. Contamination Risks: Migrated additives could accidentally transfer onto packaged products, leading to customer dissatisfaction and potential recalls.

Constructive Solutions for PE Film Additive Blooming

1. Formulation and Processing Adjustments:

Optimize Additive Usage: Consider reducing the quantity of low molecular weight additives and opting for higher molecular weight lubricants, such as high-density polyethylene wax, to improve stability.

Blend for Balance: Combining lubricants with varying melting points can create a synergistic effect that minimizes the risk of excessive migration.

Refine Processing Conditions: Fine-tune processing temperatures and extrusion speeds to limit friction and overheating that could promote additive migration.

2. Enhance Raw Material Quality Control:

Ensure that you source masterbatch materials from reputable suppliers, as poor-quality materials may contain small molecule impurities that contribute to powdering challenges.

3. Explore High-Performance Slip Agents:

If traditional slip agents lead to ongoing issues, it may be time to implement more advanced solutions. SILIKE’s copolymer siloxane-based slip agents are designed for optimal stability and compatibility with PE resins.

Why Choose SILIKE’s copolymer siloxane-based s super slip and anti-blocking Additives?

1. Superior Slip and anti-blocking: This plastic film slip agent reduces sticking during processing while maintaining excellent clarity.

2. Thermal Resilience: Its unique copolymer structure ensures reliable performance even in high-temperature settings.

3. Minimized Powdering Risk: Strong compatibility with PE helps reduce migration and powdering risks effectively.

4. Streamlined Processing: Non-Precipitation Slip Agent Masterbatch supports smooth printing, lamination, and sealing processes.

5. Improved Production Efficiency: The lubricating properties enhance processing efficiency, reduce equipment wear, and boost overall throughput.

A Note on Implementation: Before transitioning to new slip additives, it’s beneficial to conduct trials under your specific processing conditions. Reach out to SILIKE for complimentary samples of SILIKE super slip and anti-blocking SILIMER 5064MB to experience the benefits firsthand.

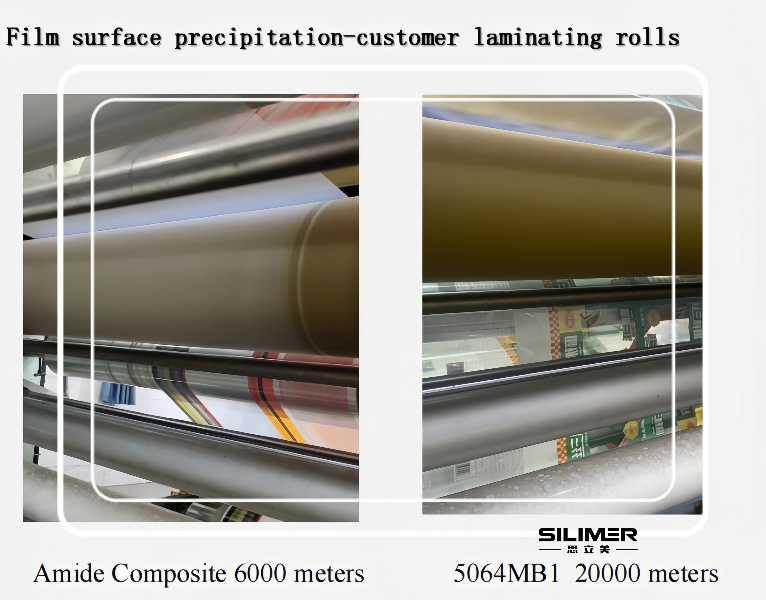

By proactively addressing powdering issues through strategic formulation adjustments, enhanced raw material quality control, and the adoption of high-performance, non-migratory super-slip additives—such as SILIKE Silicone Slip Masterbatch SILIMER 5064MB1 for PE films or non-blooming slip agent SILIMER 5064MB4 for polyethylene films—you can significantly improve the quality and efficiency of your PE film processing.

Embrace these solutions to achieve smoother production and explore SILIKE’s innovative premium polyethylene slip masterbatches to revolutionize your process. As a trusted manufacturer of slip and anti-block masterbatches, SILIKE delivers cutting-edge performance.

Post time: Apr-03-2025