Polypropylene cast film (CPP film) is a kind of unstretched flat film extrusion film produced by the method of casting, which has the characteristics of good transparency, high gloss, good flatness, easy to heat sealing, etc. The surface can be used for aluminium plating, printing, compounding, etc. after corona treatment, so it is widely used in the packaging of foodstuffs, daily necessities, electronic products and so on.

One of the characteristics of CPP film is its transparency, and its performance directly affects the packaging grade. Factors affecting the transparency of CPP film have two major categories: formulation and production process. Formulation includes the main material and auxiliary materials; production process: melt temperature and cooling roller temperature, die lip gap, air gap height (i.e., the distance between the die lip and the cooling roller), the vacuum box vacuum, air box air volume, and so on.

The influence of the main material on the transparency of polypropylene cast film CPP

The main material of CPP film is generally used for melt flow rate of 6~12g/10min resin, divided into homopolymer PP, binary copolymer PP, terpolymer PP, usually, the transparency of copolymer PP is better than homopolymer, but the stiffness of homopolymer PP is better than copolymer, and the homopolymer PP does not have the heat sealability, copolymer PP has a good sealing properties, especially the terpolymer PP, with good low-temperature heat sealability. Copolymer PP has good heat sealability, especially ternary copolymer PP, has good low temperature heat sealability, how to match according to the application requirements of the film.

The effect of auxiliary materials on the transparency of polypropylene cast film CPP

The auxiliary materials of CPP film include anti-blocking agent/opening agent, slip agent, antistatic agent, etc. The main component of opening agent is silica. The main component of the opening agent is silicon dioxide, it is appropriate to use synthetic silicon dioxide, its particles are smooth, uniform, and have a small impact on the transparency of the film; smooth agent, antistatic agent with smoothness, add the right amount of smooth agent, antistatic agent, improve the smoothness and antistatic properties at the same time, it is conducive to improving the film’s gloss, which is conducive to the improvement of the transparency.

The effect of amide additives on the transparency of polypropylene cast film CPP

Common film slip agents are amides: The primary role of amide additives (erucic acid amides, oleic acid amides, etc.) in the production of polyolefin films is to impart slip properties. The addition of the slip agent acts as a built-in reservoir of lubricant for the polymer matrix, which migrates to the surface of the polymer film immediately after leaving the mould. The fatty acid amides are soluble in the amorphous melt during processing, but as the polymer cools and begins to crystallise, the slip agent is extruded from the hardening polymer matrix. It reaches the surface and forms a lubricating layer, resulting in a smooth surface.

However, due to the composition, structural characteristics and small molecular weight of traditional film slip agents (amides), they are very easy to be precipitated or powdered, and if they are added in excess, a fog layer will be formed on the surface of the film as a result of their large amount of outward migration, resulting in a decrease in transparency. At the same time, due to uneven dispersion of the film appears horizontal or vertical stripes, and greatly reduces the effect of the talcum agent, the coefficient of friction will be unstable due to different temperatures, the need to clean the screw regularly, and may cause damage to the equipment and products. In blown film processing, white powder is easily precipitated on the film surface due to the migration of the slip agent to the surface, and it is also easy to leave powder on the rollers.

SILIMER series of non-precipitating film slip agents have high stability and are not easy to precipitate, and at the same time, they do not affect film heat-sealing and laminating, do not affect printing, and have stable friction coefficients. It is suitable for plastic film production, food packaging materials, pharmaceutical packaging materials manufacturing, and so on.

SILIKE SILIMER series Non-migratory Slip and Anti-Block Film Additives, Does not affect the transparency of CPP polypropylene cast film.

SILIKE non-precipitation slip agent masterbatch SILIMER 5065, SILIMER 5065HB is a super-slip masterbatch with long chain alkyl-modified siloxane masterbatch containing antiblock additive. It is mainly used in CPP films, oriented flat film applications and other products compatible with polypropylene. It can significantly improve anti-blocking & smoothness of the film, and the lubrication during processing, can greatly reduce the film surface dynamic and static friction coefficient, make the film surface more smooth.

At the same time, SILIKE Novel non-migratory super slip&Anti-blocking agent SILIMER 5065HB has a special structure with good compatibility with the matrix resin, no precipitation, no sticky, and no effect on the transparency of film.

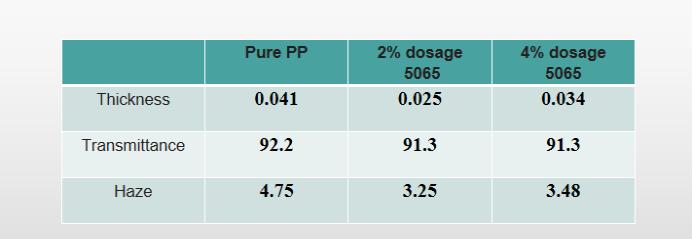

SILIKE SILIMER 5065, SILIMER 5065HB Transparency test in PP film:

What are the benefits of adding SILIKE non-Blooming slip agent series SILIMER 5065 to CPP polypropylene cast film processing?

1.SILIKE SILIMER 5065, SILIMER 5065HB can Improve surface quality including no precipitation, no sticky, no effect on transparency, no effect on the surface and printing of film, lower Coefficient of friction,better surface smoothness;

2.SILIKE SILIMER 5065, SILIMER 5065HB Improve processing properties including better flow ability,faster throughput ;

3.SILIKE SILIMER 5065, SILIMER 5065HB has Good anti-blocking & smoothness, lower Coefficient of friction, and better processing properties in PP film.

SILIKE SILIMER non-Blooming slip agent series provide an excellent solution for controlling the CPP polypropylene cast film quality, from Cast Polypropylene Films, PE-blown films to Various multiple composite functional films. By addressing the migration issues of traditional slip agents and significantly improving the performance and appearance of packaging films, SILIKE offers a reliable choice for flexible packaging material manufacturers and printing companies.

Contact us Tel: +86-28-83625089 or via email: amy.wang@silike.cn.

website:www.siliketech.com to learn more.

Post time: Oct-09-2024