Shoe soles play a crucial role in determining the overall quality and performance of footwear. The abrasion resistance of shoe soles is one of the key factors that directly affect the service life and durability of shoes. With the continuous development of the footwear industry and the increasing demands of consumers for high-quality shoes, the research and development of effective Anti-abrasion agent for shoe sole materials have become extremely important. Silicone masterbatch, as a promising material, has shown excellent performance in enhancing the abrasion resistance of shoe soles and has attracted extensive attention in recent years.

SILIKE Anti-abrasion masterbatches NM series is particularly developed for the footwear industry. Currently, we have 4 grades that are respectively suitable for EVA, PVC, TPR, TR, RUBBER and TPU shoe’s sole. A small addition of them can effectively improve the final item’s abrasion resistance and decrease the abrasion value in the thermoplastics. Effective for DIN, ASTM, NBS, AKRON, SATRA, GB abrasion tests.

Firstly, SILIKE Anti-Wear Agent exhibits excellent lubricity, which can reduce the friction coefficient between the shoe sole and the ground surface, thereby effectively reducing abrasion. Secondly, silicone masterbatch has good thermal stability, which enables it to maintain stable performance under various temperature conditions and is suitable for different manufacturing processes and usage environments of shoe soles.

Abrasion Resistance Improvement

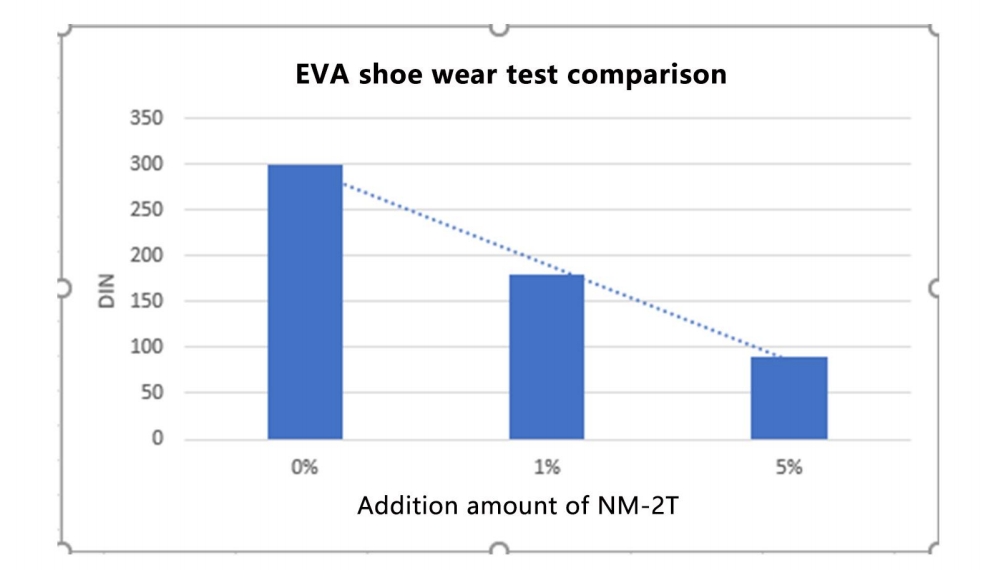

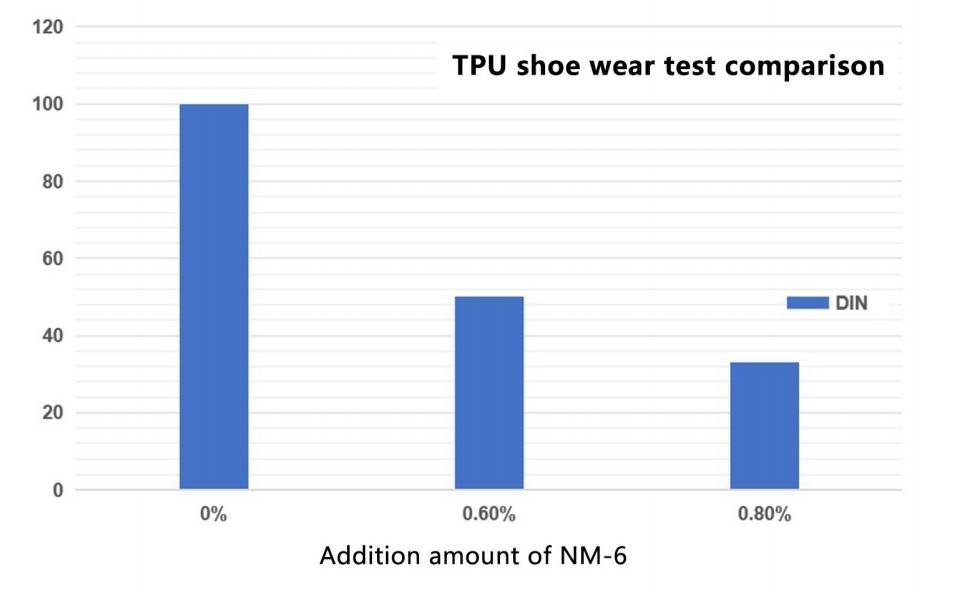

The addition of silicone masterbatch abrasion resistant agent NM2T, Anti-Wear Agent NM6 to shoe sole materials can significantly enhance the abrasion resistance.

The amount of SILIKE Anti-abrasion masterbatches added is small, and a small amount of addition can improve the surface wear resistance and processing lubrication performance of the sole material, and the processing is simple, SILIKE Anti-abrasion masterbatch may be processed in the same way as the resin carrier on which they based. It can be used in classical melt blending process like Single /Twin screw extruder, injection molding. A physical blend with virgin polymer pellets is recommended.

Manufacturers engaged in the footwear outsole material industry, if you want to improve the wear resistance of sole materials and processing lubrication performance, please contact us, SILIKE Anti-abrasion agent agents are widely used in PVC, EVA, TPU, TPR, TR and rubber.

Chengdu SILIKE Technology Co., Ltd, a Chinese leading Silicone Additive Supplier for modified plastic, offer innovative solutions to enhance the performance and functionality of plastic materials. Welcome to contact us, SILIKE will provide you with efficient plastics processing solutions.

Contact us Tel: +86-28-83625089 or via email: amy.wang@silike.cn.

website: www.siliketech.com to learn more.

Post time: Dec-18-2024