April 18, 2025, Shenzhen – The 37th CHINAPLAS International Plastics & Rubber Exhibition wrapped up triumphantly at the Shenzhen World Exhibition & Convention Center (Baoan), reaffirming its status as the global epicenter of plastics innovation. Under the theme “Transformation · Collaboration · Co-Creating a Sustainable Future”, this year’s event spanned 380,000 sqm, attracting over 4,500 exhibitors and more than 270,000 professional visitors.

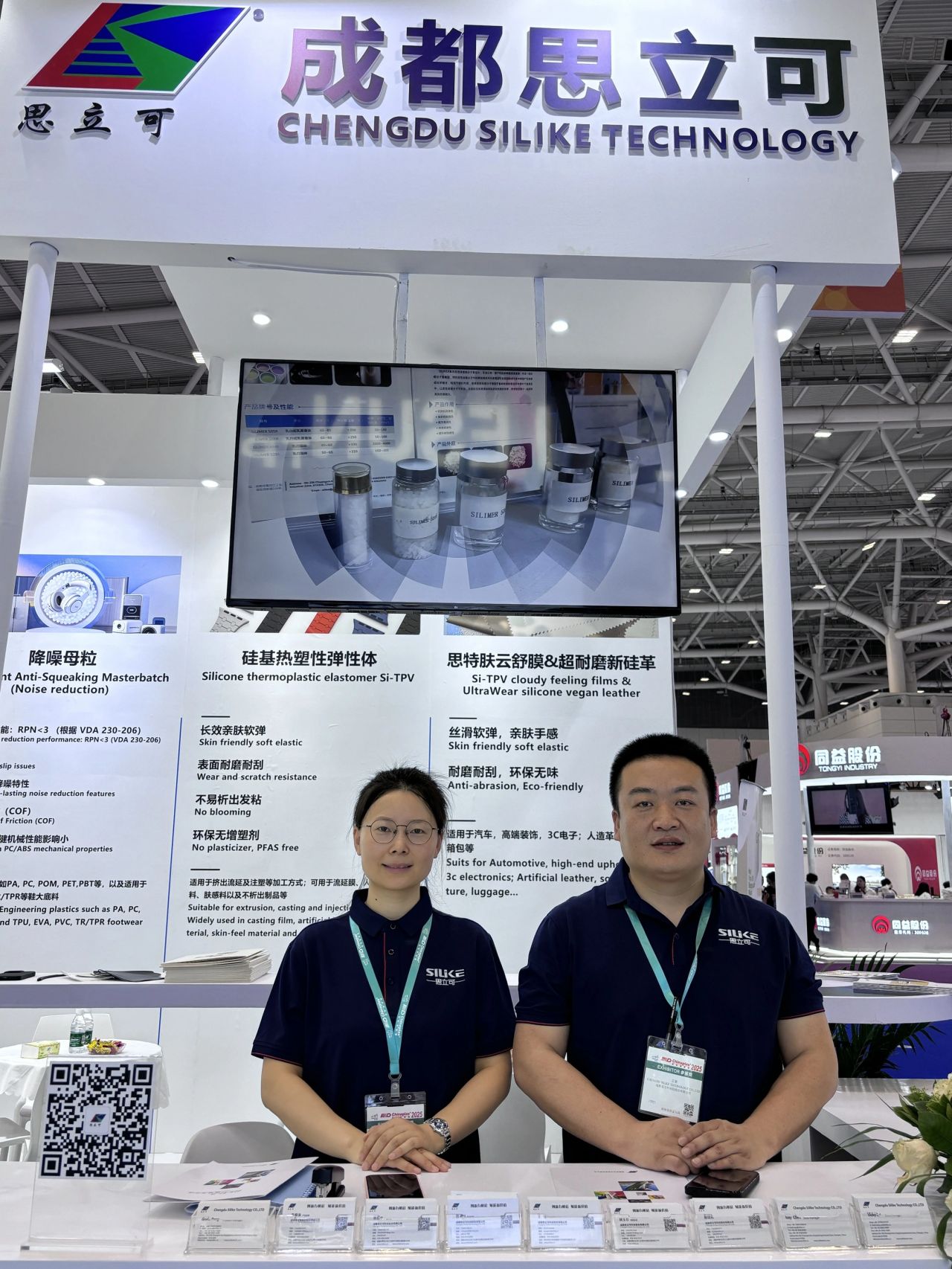

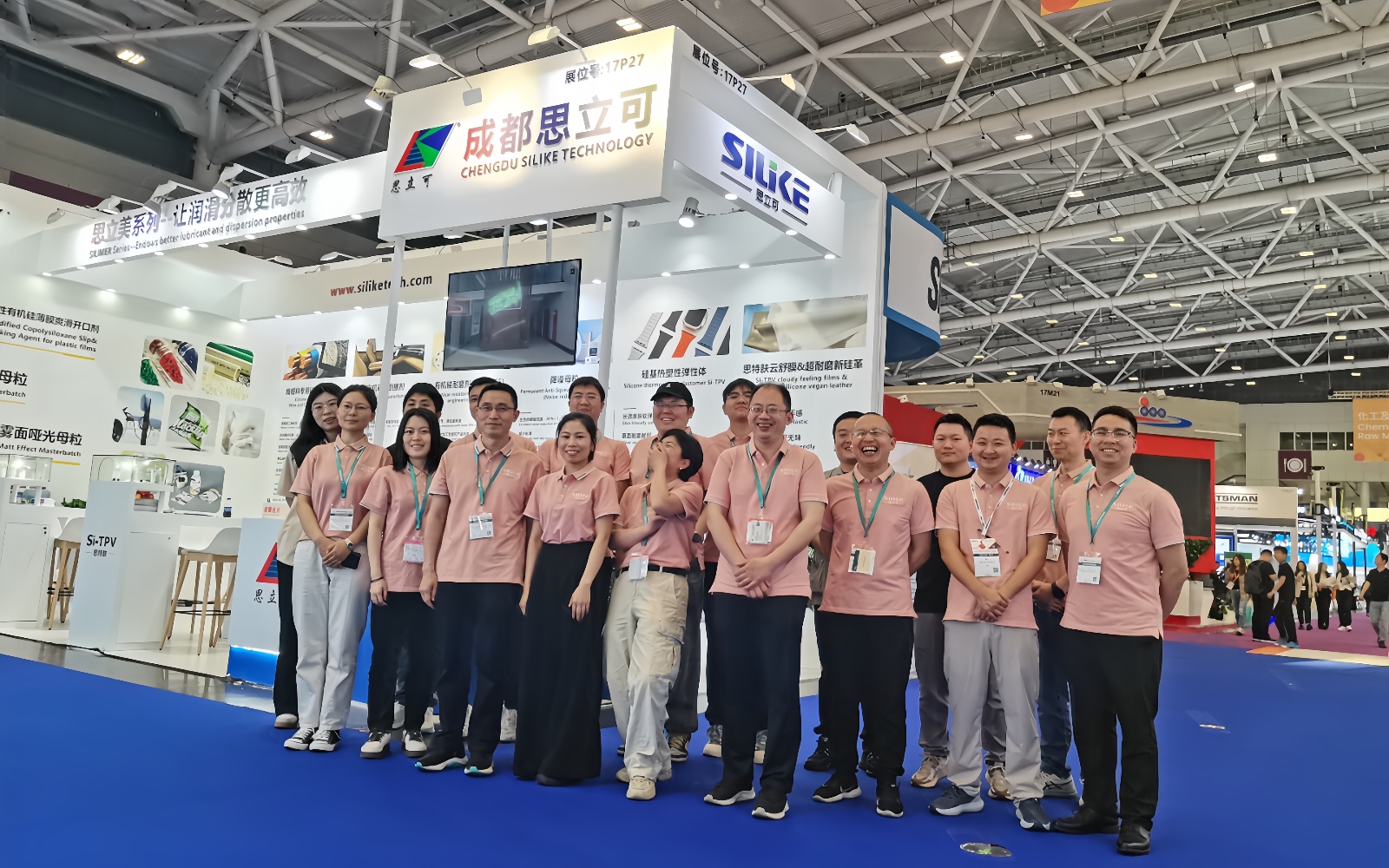

From April 15 to 18, Chengdu Silike Technology Co., Ltd attended Chinaplas 2025. Now, take you back to the highlights!

Silike’s Breakthroughs: Where Technology Meets Sustainability

As a pioneering innovator in silicone additive solutions, Silike remains steadfast in its commitment to innovation-driven growth and green and sustainable development. By relentlessly advancing the boundaries of silicone technology, we enable material performance breakthroughs and inject transformative value into the plastics and rubber industries. At this exhibition, we showcased a comprehensive portfolio of high-performance, eco-friendly plastic processing additives and material solutions. These innovations are designed to address critical industry challenges while aligning with global sustainability goals, delivering greener, more efficient, and superior-quality products and services to global clients.

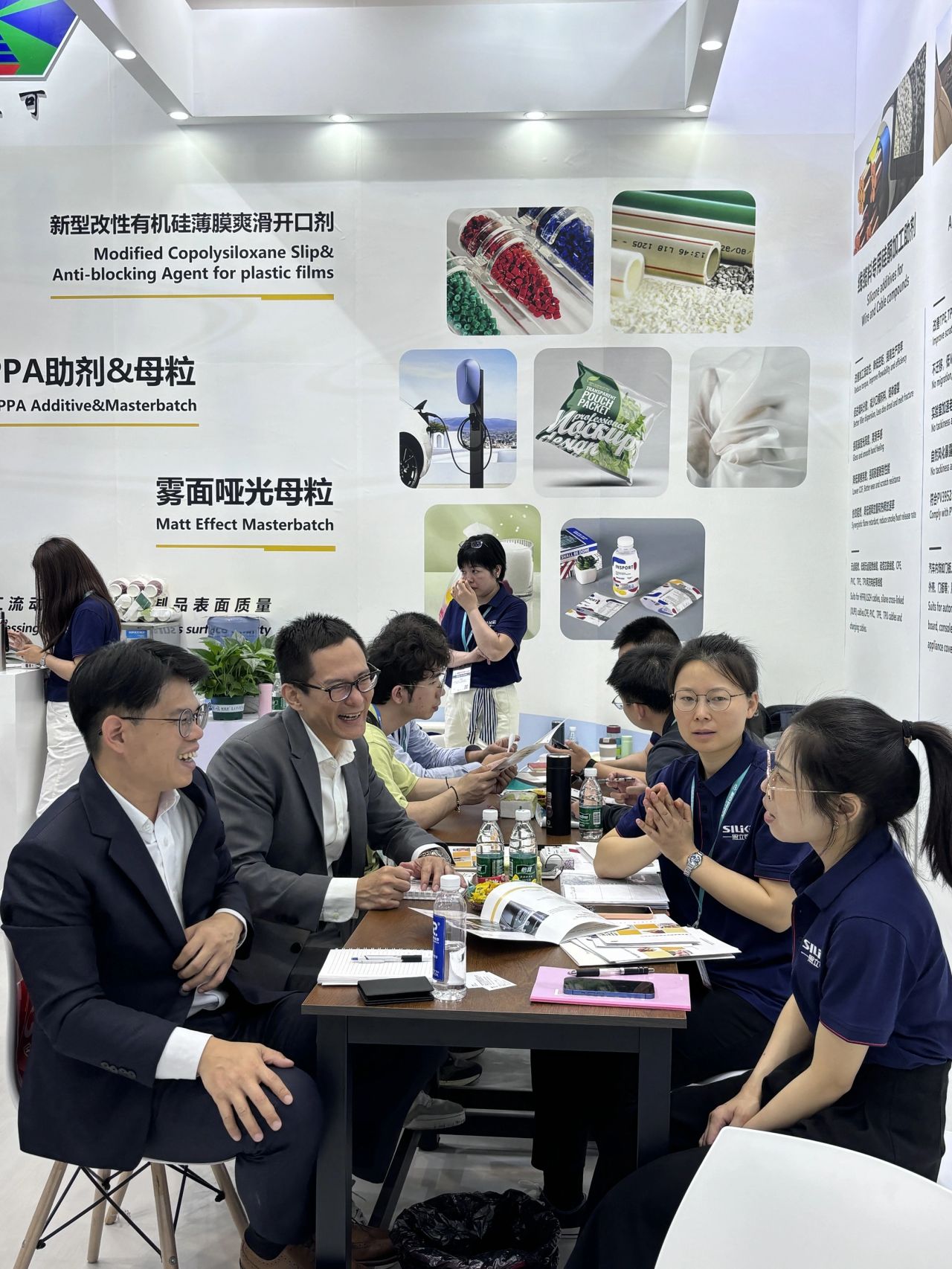

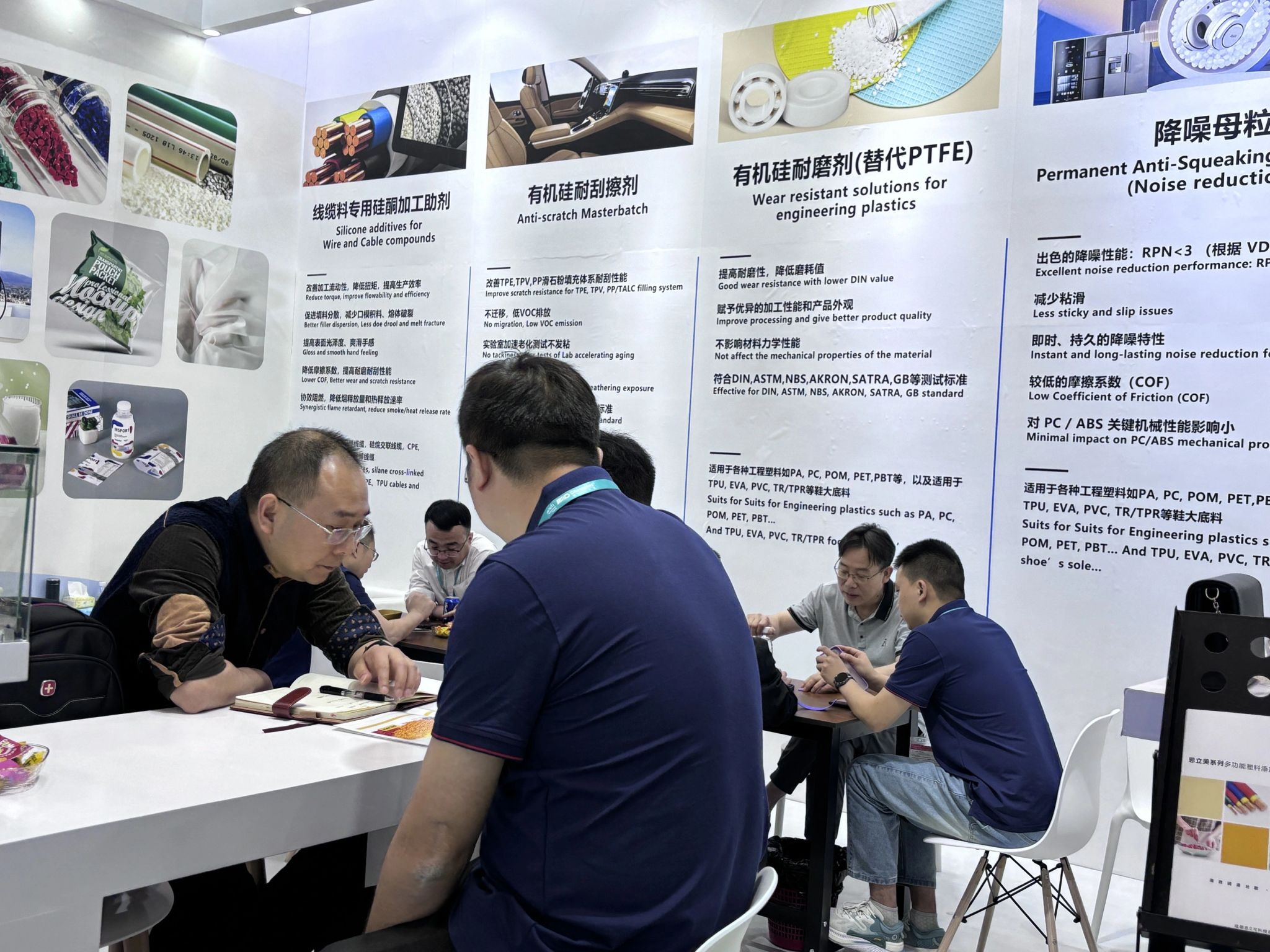

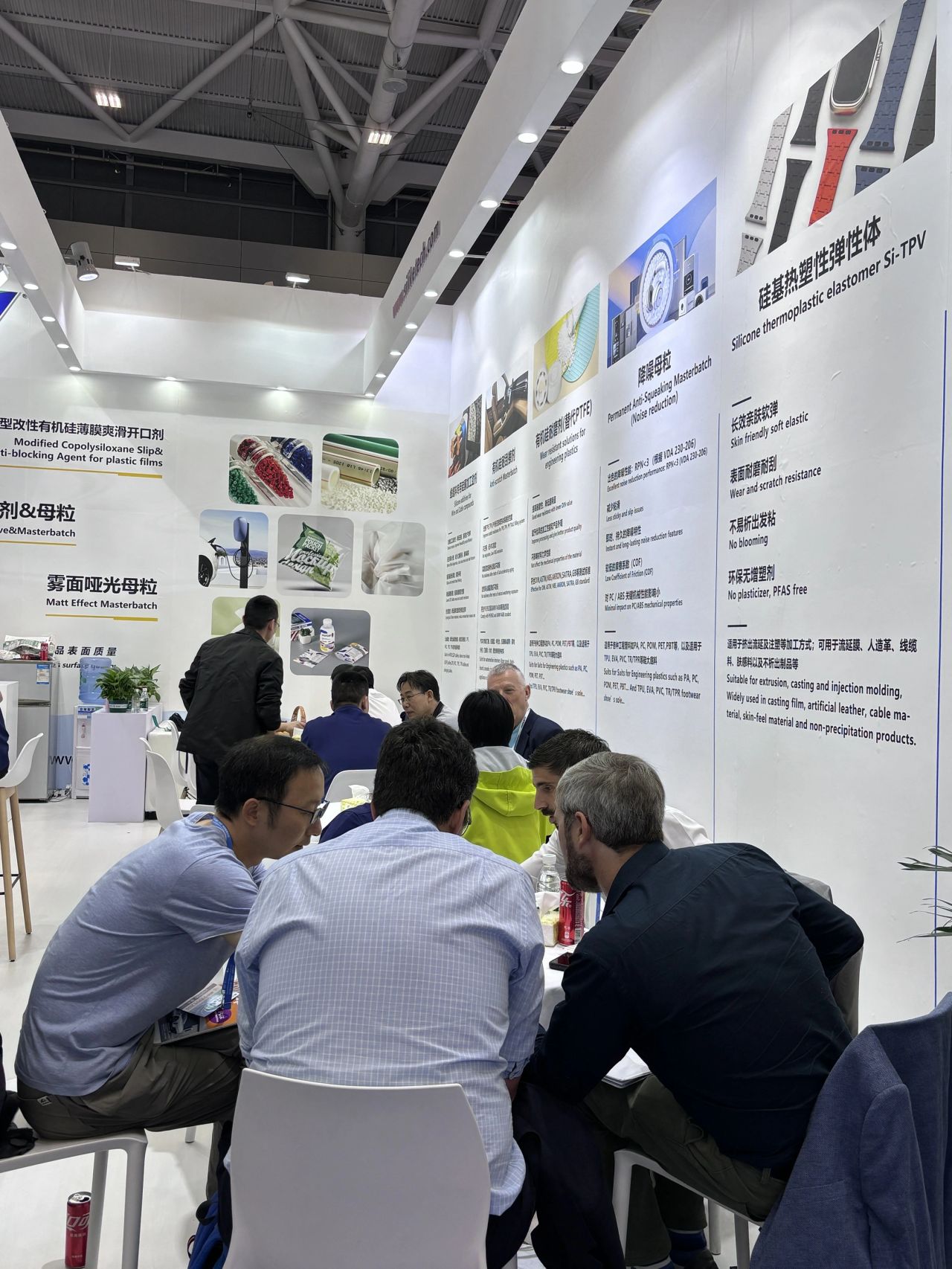

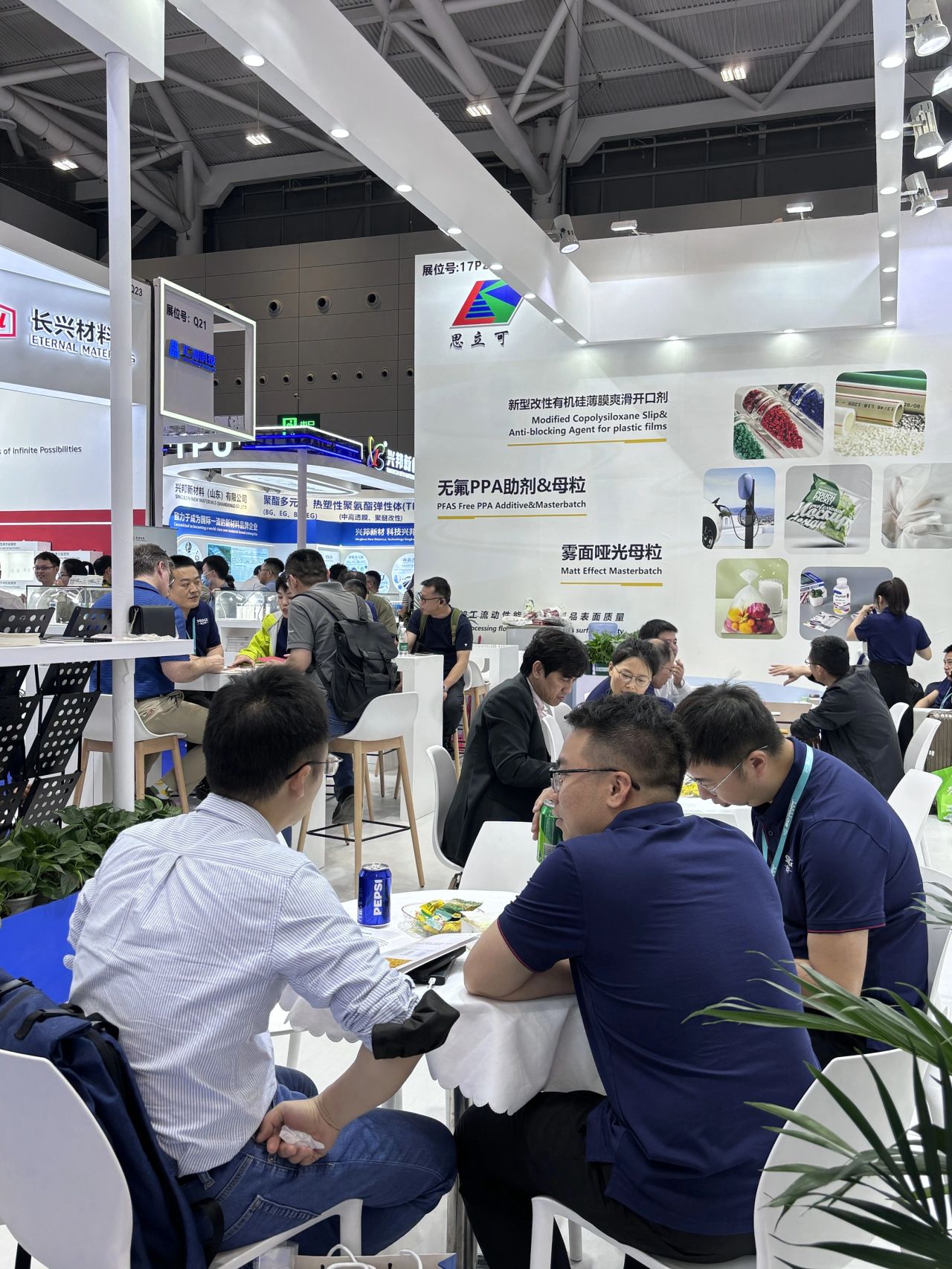

At the exhibition, Silike Technology’s booth captivated the audience with its innovative technology and futuristic design. Our meticulously crafted experience zone, featuring immersive technology demonstrations and industry trend insights, drew packaging giants, automotive suppliers, electronics brands, and footwear innovators, reinforcing Silike’s role as a trusted sustainability partner.

Key highlights included:

Long-Lasting Film Slip & Anti-Block Agents

Applications: PE blown films, CPP, BOPP, EVA, TPU films,cast films, extrusion coatings

Innovation: No blooming/bleeding, stable friction coefficient, and no compromise on printability or heat sealing—solving the long-standing trade-off between film performance and production stability.

PFAS Free PPA Additives & Masterbatches

Applications: films, pipes, wires&cables, synthetic turf, monofilaments,masterbatches, and petrochemical industries.

Advantage: Reduce melt viscosity, improve internal/external lubrication, eliminate melt fracture, minimize die buildup & increases output while complying with the EU’s strict PFAS regulations, offering a seamless shift to greener, high-efficiency processing.

Sensory Revolution: Matte TPU & Soft-Touch Granules

Applications: Si-TPV UltraWear Silicone Vegan Leather, film, wire and cables, automotive interiors, high-end decor, 3C electronics, apparel packaging and more…

Breakthrough: Delivers skin-friendly, ultra-soft, scratch-resistant, and abrasion-resistant finishes—DMF-free with no plasticizer migration, ideal for luxury tactile experiences.

Biodegradable Material Modifiers

Focus: Specially developed for biodegradable polymers such as PLA, PCL, and PBAT, our modifiers provide lubrication, enhanced processing performance, and improved dispersion of powdered components. Additionally, they help reduce odor during processing while maintaining mechanical properties—all without compromising the material’s biodegradability.

At the CHINAPLAS 2025, we met with many new and old customers and showed them many new environmentally friendly materials, they showed great interest in our products, and both sides hope to further strengthen and deepen the cooperation.

CHINAPLAS 2025 Trends: The Future is Green & Smart

1. Green Materials Take Center Stage

Bio-based polymers (e.g., Arkema’s Rilsan® PA11, with an 80% lower carbon footprint) and chemically recycled resins (Kingfa’s ISCC-certified LCP) were major focal points.

Regulatory drivers: The EU’s PPWR (Packaging & Packaging Waste Regulation) and PFAS restrictions accelerated demand for sustainable alternatives.

2. Smart Manufacturing Gains Momentum

AI-driven production (e.g., KraussMaffei’s APC Plus) and cloud-based process optimization tools demonstrated the rapid adoption of Industry 4.0 solutions.

Digital twins and predictive maintenance emerged as critical technologies for improving efficiency and reducing downtime.

3. Cross-Industry Collaboration Expands

New Energy: Advanced materials for EV battery casings and lightweight composites to enhance performance and sustainability.

Healthcare: Increased use of anti-microbial polymers for medical devices and single-use alternatives to minimize contamination risks.

…

A Grateful Farewell

Silike extends heartfelt thanks to all partners, clients, and visitors who joined us at CHINAPLAS 2025. Together, we’ve proven that sustainability and innovation go hand in hand.

Chengdu Silike Technology Co., Ltd., established in 2004, stands as a pioneering leader in China’s rubber and plastics industry, specializing in the innovative integration of silicone technology with polymer science. With over 20 years of dedicated R&D, the company has revolutionized the application of silicone in plastics, bridging two parallel disciplines to develop cutting-edge solutions that address critical industry challenges. Its breakthrough product portfolio includes silicone masterbatches, silicone powders, the modified SILIMER® series, non-migrating slip/anti-block agents, fluorine-free PPA masterbatches, silicone super-dispersants, Anti-squeaking Masterbatch, Additive Masterbatch For WPC, Si-TPV dynamic vulcanizated thermoplastic Silicone-based elastomers , and high-performance wear-resistant additives for footwear.

These innovations are widely adopted across industries such as footwear, wire & cable, automotive interiors, films, synthetic leather, and smart wearables, effectively breaking foreign technology monopolies, enabling import substitution, and filling gaps in the domestic market.

Silike provides comprehensive solutions to enhance thermoplastic performance—delivering superior abrasion/scratch resistance, surface smoothness, low friction coefficients, optimized mold release, and flawless filler dispersion.

In addition, leveraging advanced technical expertise, we tailor formulations to meet specific application needs. By combining scientific rigor with a client-centric approach, Silike’s silicone-based additive and Si-TPV raw materials empower manufacturers to achieve both performance excellence and cost efficiency.

Let’s meet again in Shanghai at CHINAPLAS 2026!

Post time: Apr-22-2025