Polypropylene (PP), one of the five most versatile plastics, is used in a wide range of applications in everyday life, including food packaging, medical equipment, furniture, automotive parts, textiles and more. Polypropylene is the lightest plastic raw material, its appearance is colourless translucent particles, as a food-grade plastic, is widely used in food packaging, such as Styrofoam boxes, PP plastic cups and so on.

Polypropylene (PP) can be divided into five main categories according to its main uses: PP injection moulding, PP drawing, PP fibre, PP film, PP pipe.

1. PP injection molding: Polypropylene injection plastic is primarily utilized in small household appliances, toys, washing machines, auto parts, and other applications.

2. PP wire drawing: Polypropylene wire drawing is mainly employed in the production of plastic woven products such as daily use container bags, woven bags, food bags, and transparent bags.

3. PP film: Polypropylene film is generally categorized into BOPP film, CPP film, IPP film and is predominantly used in food packaging. Compared to PE bags, PP film food bags offer superior transparency, hardness and surface quality.

4. PP fiber: Polypropylene fiber is a product made from polypropylene raw material through melt spinning process and finds its main applications in decoration, clothing manufacturing and diaper production.

5. PP pipe: Due to its non-toxicity and high temperature resistance characteristics, polypropylene pipe material is primarily utilized in water supply and heating systems. In comparison with PE pipes, PP pipes are lighter in weight for convenient transportation while also offering good environmental performance with recyclability.

Polypropylene (PP) exhibits excellent wear resistance, self-lubricating properties, high toughness, and good impact resistance. Wear resistance is a crucial performance indicator for polypropylene in many application areas, particularly in mechanical, automotive, and electronics industries where there are stringent requirements for material durability. Improving wear resistance can significantly enhance product durability and reliability while reducing maintenance costs and extending product lifespan, thereby increasing the cost-effectiveness and market competitiveness of the products.

To improve the wear resistance of polypropylene (PP), the following methods can be taken:

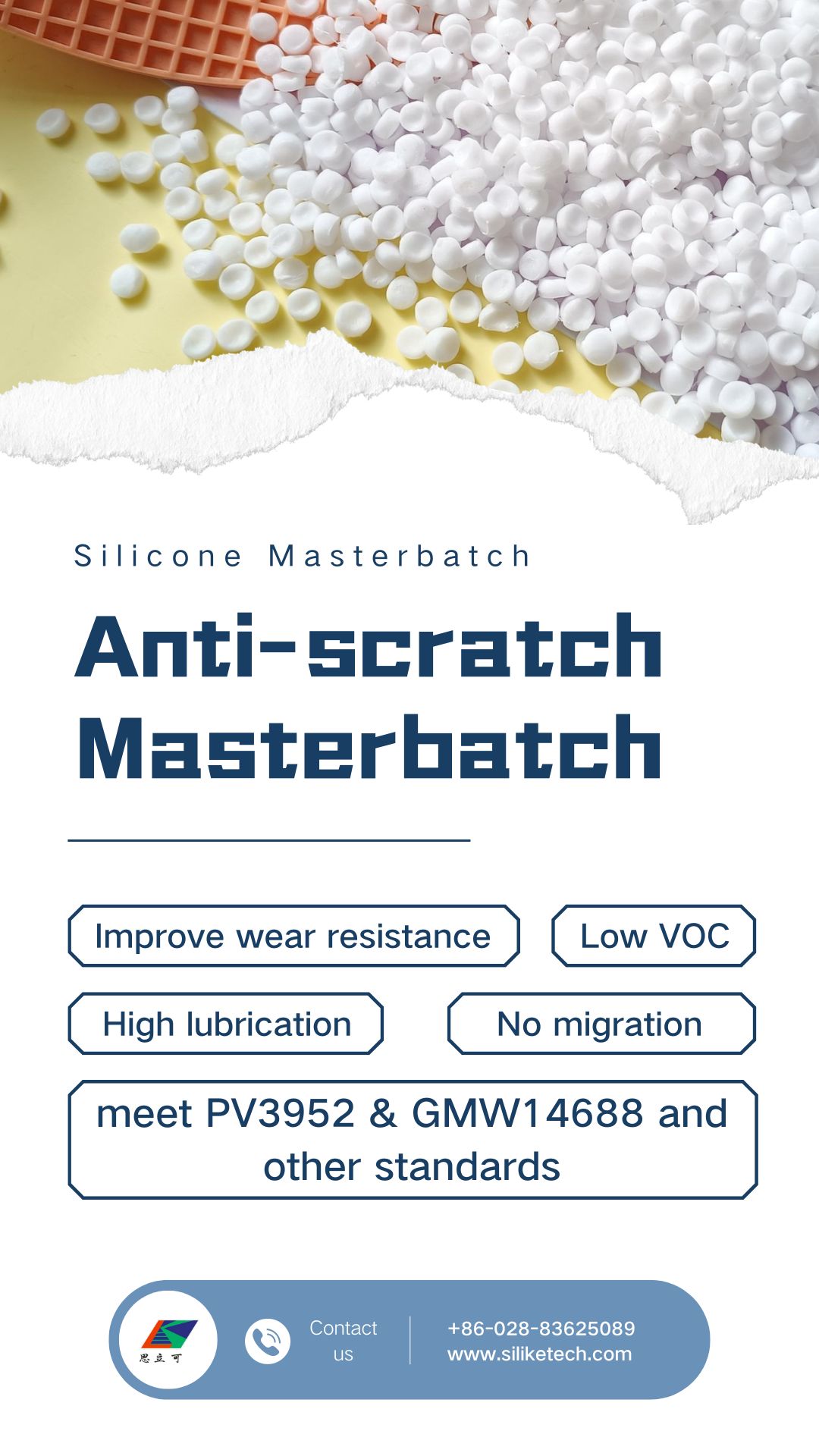

1. Add silicone masterbatch abrasion-resistant additive: Specific processing aids, such as SILIKE Anti-Scratch Silicone Masterbatch LYSI-306H, can be added to the raw materials and mixed evenly to improve the wear resistance of polypropylene.

2. Filling modification: During the PP molding process, fillers such as silicates, calcium carbonate, silica, cellulose, glass fiber, etc. can be added to improve the heat resistance, rigidity of PP, and also help improve its wear resistance.

3. Blending modification: Blending PP with other materials such as polyethylene, engineering plastics, thermoplastic elastomers or rubber can improve PP’s performance in multiple ways, including wear resistance.

4. Reinforcement modification: Using fiber materials such as glass fiber to reinforce PP can significantly improve the plastic material’s strength and heat resistance, thereby improving its wear resistance.

SILIKE Anti-Scratch Silicone Masterbatch, Significantly improve the wear resistance of polypropylene surface

SILIKE Anti-scratch masterbatch has an enhanced compatibility with the Polypropylene (CO-PP/HO-PP) matrix — Resulting in lower phase segregation of the final surface, which means it stays on the surface of the final plastics without any migration or exudation , reducing fogging , VOCS or Odors . Helps improve long-lasting anti-scratch properties of automotive interiors , by offering improvements in many aspects like Quality, Aging , Hand feel, Reduced dust buildup… etc. Suitable for variety of Automotive interior surface , such as : Door panels, Dashboards, Center Consoles, instrument panels…

Compare to conventional lower molecular weight Silicone / Siloxane additives, Amide or other type scratch additives, SILIKE Anti-scratch Masterbatch LYSI-306H is expected to give a much better scratch resistance, meet PV3952 & GMW14688 standards. Suitable for variety of Automotive interior surface , such as : Door panels, Dashboards, Center Consoles, instrument panels…

The benefits of SILIKE Anti-Scratch Silicone Masterbatch LYSI-306H

(1) Improves the anti-scratch properties of TPE,TPV PP,PP/PPO Talc filled systems.

(2) Operates as a permanent slip enhancer

(3) No migration

(4) Low VOC emission

(5) No tackiness after laboratory accelerating aging test and natural weathering exposure test

(6) meet PV3952 & GMW14688 and other standards

The applications of SILIKE Anti-Scratch Silicone Masterbatch LYSI-306H

1) Automotive interior trims like Door panels, Dashboards, Center Consoles, instrument panels…

2) House appliances covers

3) Furniture / Chair

4) Other PP compatible system

If you are looking for plastic modifiers, wear agents, please contact SILIKE, SILIKE is a leading provider of modified plastic additives, offering innovative solutions to enhance the performance and functionality of plastic materials. With years of experience and expertise in the industry, we specialize in developing and manufacturing high-quality additives that improve the mechanical, thermal, and processing properties of plastics.

Contact us Tel: +86-28-83625089 or via email: amy.wang@silike.cn.

website:www.siliketech.com to learn more.

Post time: Jun-20-2024