Polymer Processing Additives (PPA) is a general term for several types of materials used to improve the processing and handling properties of polymers, mainly in the molten state of the polymer matrix to play a role. Fluoropolymers and silicone resin polymer processing aids are mainly used in polyolefin polymers.

PPA can be applied to materials including LLDPE, LDPE, HDPE, MDPE, PP, thermoplastic elastomers, PS, nylon, acrylic resins, PVC and so on. The fields of application can be blown film, cast extrusion, wire and cable, pipe and sheet extrusion, masterbatch processing, hollow blow molding, and so on.

The main role of Polymer Processing Aid (PPA) in wire and cable production and processing is to improve polymer processing performance and product quality. The following are some of the main reasons for adding PPA:

1. Reduced Melt Viscosity: PPA can reduce the melt viscosity of polymers, making them easier to flow during processing and improving extrusion speed and productivity.

2. Improved Product Appearance: PPA can improve the surface gloss and flatness of wire and cable products, reduce appearance defects and imperfections, and improve product aesthetics and value.

3. Reduce energy consumption: Since PPA reduces the melt viscosity of the polymer, lower processing temperatures, and pressures are required during extrusion, thus reducing energy consumption and costs.

4. Improved extrusion stability: The addition of PPA improves the flow and melt stability of the polymer, reducing alternating extrusion and deterioration during extrusion, resulting in a more stable product in terms of size and quality.

In general, the addition of polymer processing aids PPA can improve the production and processing performance of wire and cable, and improve product quality and efficiency. But with the proposed ban on fluoride, finding alternatives to fluorinated PPA has become a new challenge.

To address this dilemma, SILIKE has introduced a PTFE-free alternative to Fluorine-based PPA ——a PFAS-free polymer processing additive (PPA). This Fluorine-free PPA MB, PTFE-free additive is an organically modified polysiloxane masterbatch that utilizes the excellent initial lubrication effect of polysiloxanes and the polarity of the modified groups to migrate and acting on the processing equipment during processing.

PFAS-free polymer processing aids (PPA)——helping wire and cable production to be more efficient >>

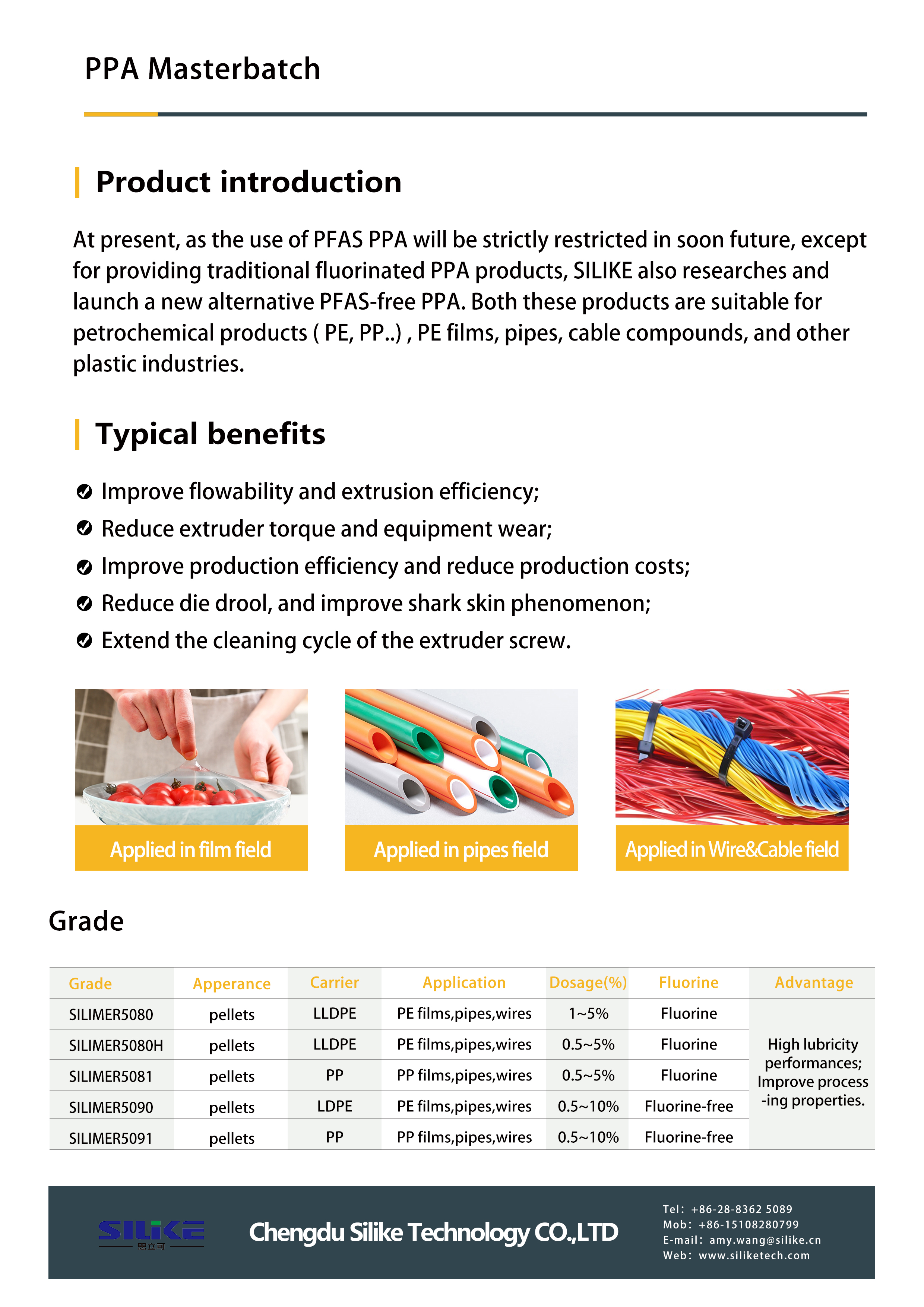

SILIKE develops fluorine-free PPA as a perfect replacement for fluorinated PPA processing aids, a small addition of SILIKE SILIMER-5090 Non-fluoropolymer processing additive improves wire and cable processing performance. Effectively reduces die head pressure, improves extrusion stability, reduces extrusion pulsation, eliminates die head build-up, significantly improves processing fluidity, reduces torque and improves productivity. Improve the surface quality and smoothness of products.

SILIKE PFAS-free polymer processing aids (PPA) have a wide range of applications for cables, films, tubes, masterbatches, artificial grass, etc.

Typical performance:

Improved processability

Efficient lubrication and dispersion

Improved processing efficiency

Eliminates melt breakage

Reduces die drool and die build-up

Below are the recommended grades of SILIKE PPA processing aids, you can view them. If you have any questions, please do not hesitate to contact me. SILIKE looks forward to providing you with solutions for fluorine-free PPA in wire and cable applications.

Post time: Nov-10-2023