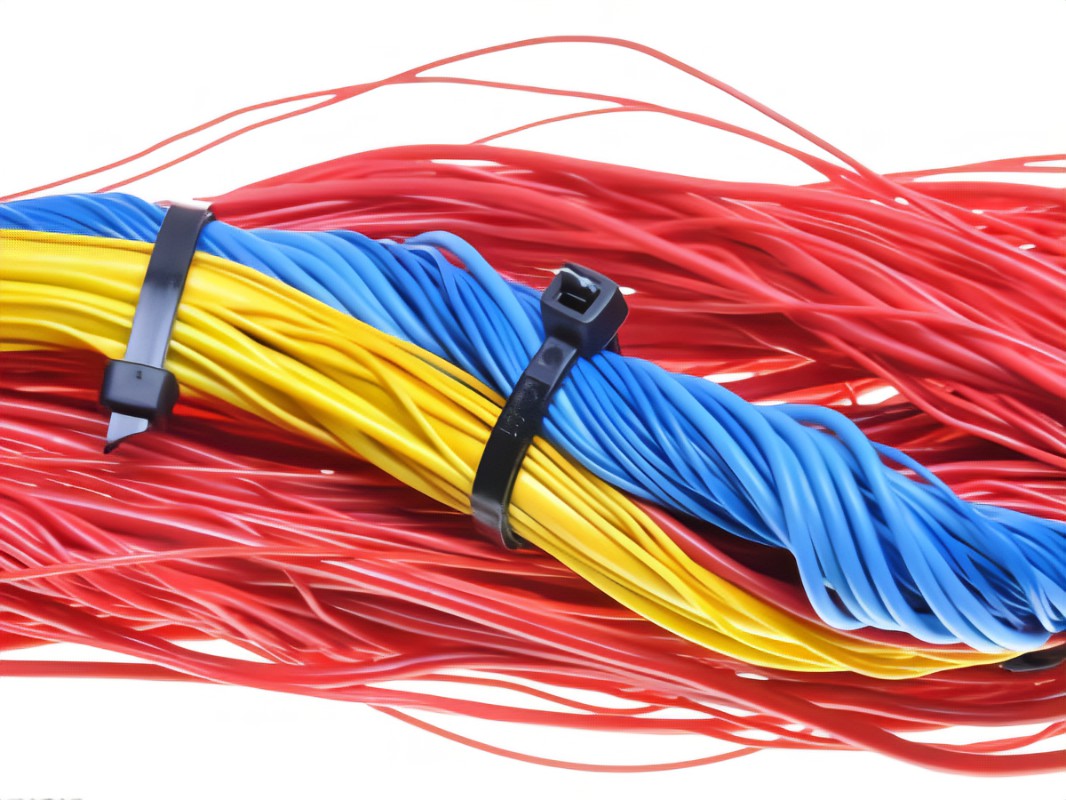

PVC cable material is composed of polyvinyl chloride resin, stabilizers, plasticizers, fillers, lubricants, antioxidants, coloring agents, and so on.

PVC cable material is inexpensive and has excellent performance, in wire and cable insulation and protection materials have long occupied an important position, but this material in the processing of many problems. With the market demand for cable material performance improvement, the PVC cable material also put forward higher requirements.

In the production of PVC wire and cable material granulation, the following common quality problems may occur:

Appearance defects: Marks, scratches, bubbles, uneven colors, and other problems on the surface of the product, affecting the aesthetics and market competitiveness of the product.

Dimensional deviation: The dimensions of the product, such as length, diameter, or thickness, are out of the specified range, leading to difficulties in installation and use or increased risk of failure.

Mechanical properties not up to standard: the mechanical properties of the products such as tensile strength, bending performance, impact resistance, etc. do not meet the requirements, reducing the reliability and durability of the products.

Poor thermal stability: the product is easy to soften, deform, or age under a high-temperature environment, which affects the service life and reliability of the product.

Poor weather ability: the products easily fade, aging, crack, etc. under long-term outdoor exposure, which reduces the durability and appearance quality of the products.

These quality problems may adversely affect the use of product performance, safety, and reliability, therefore, in the PVC wire and cable material granulation production process, it is necessary to strictly implement quality control measures, such as strengthening raw material inspection, optimizing production process, strict maintenance of equipment, product testing, adding suitable wire and cable material processing aids, etc., to ensure that the product quality meets the standard requirements.

Unlocking Growth Opportunities : SILIKE Silicone Powder for Wire & Cable Manufacturers

SILIKE silicone additives are based on different resins to ensure optimum compatibility with the thermoplastic. Incorporating SILIKE LYSI series silicone masterbatch significantly improves the material flow, extrusion process, slip surface touch and feel, and creates a synergistic effect with flame-retardant fillers.

They are widely used in LSZH/HFFR wire and cable compounds, silane crossing linking XLPE compounds, TPE wire, Low smoke & low COF PVC compounds. Making wire and cable products eco-friendly, safer, and stronger for better end-use performance.

SILIKE Silicone powder LYSI-300C is a powdered formulation with 60% ultra-high molecular weight siloxane polymer and 40% silica. It is recommended to be used as a processing aid in various thermoplastic formulations such as halogen-free flame retardant wire and cable compounds, PVC compounds, engineering compounds, pipes, plastic/filler masterbatches..etc.

Compared to conventional lower molecular weight Silicone / Siloxane additives, like Silicone oil, silicone fluids, or other type processing aids, SILIKE Silicone powder LYSI-300C is expected to give improved benefits on processing properties and modify the surface quality of final products.

SILIKE silicone powder LYSI-300C can be used in classical melt blending processes like Single /Twin screw extruders, and injection molding. A physical blend with virgin polymer pellets is recommended. For better test results, Strongly suggest pre-blend Silicone powder and thermoplastic pellets prior to introduction to the extrusion process.

SILIKE Silicone powder LYSI-300C can be added in a small amount to PVC cable material to obtain good processing performance, eg, Less screw slippage, improved mold release, reduce die drool, a lower coefficient of friction, fewer paint and printing problems, and a broader range of performance capabilities.

Different formula ratios have different effects. When SILIKE Silicone powder LYSI-300C is added to polyethylene or similar thermoplastic at 0.2 to 1%, improved processing and flow of the resin is expected, including better mold filling, less extruder torque, internal lubricants, mold release, and faster throughput; At a higher addition level, 2~5%, improved surface properties are expected, including lubricity, slip, lower coefficient of friction and greater mar/scratch and abrasion resistance.

SILIKE Silicone powder is not only suitable for PVC wire&cable compounds, but also for many other applications, such as PVC compounds, PVC footwear, color masterbatches, filler masterbatches, engineering plastics, and others.

Facing challenges with processing properties or surface quality? SILIKE has the solution you need. Don’t let surface defects compromise your product quality. Contact SILIKE today to discover how our silicone powder can transform your PVC wire&cable material production! Unlock new growth opportunities for wire & cable with SILIKE. Visit our website at www.siliketech.com for more information.

Post time: Mar-01-2024