Polybutylene terephthalate (PBT), a polyester made by polycondensation of terephthalic acid and 1,4-butanediol, is an important thermoplastic polyester and one of the five major engineering plastics.

Properties of PBT

- Mechanical properties: High strength, fatigue resistance, dimensional stability, and minimal creep (even under high-temperature conditions).

- Heat aging resistance: Enhanced UL temperature index of 120-140℃ (good long-term outdoor aging resistance).

- Solvent resistance: No stress cracking.

- Water stability: PBT is prone to decomposition upon contact with water (use with caution in high-temperature, high-humidity environments).

Most PBT resin is processed into blends, modified with various additives, and blended with other resins to obtain good heat resistance, flame retardancy, electrical insulation, and other comprehensive performance characteristics, as well as good processing performance. It is widely used in electrical appliances, automobiles, aircraft manufacturing, communications, home appliances, transportation, and other industries.

PBT Applications

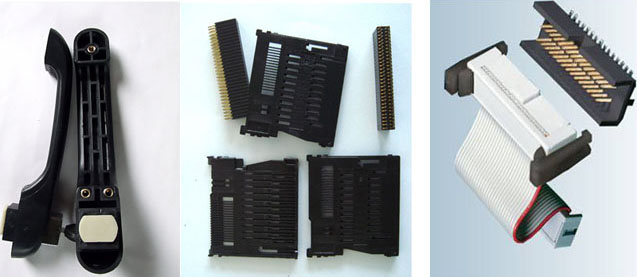

- Electronics and Electrical Appliances: No-fuse disconnectors, electromagnetic switches, transformers, appliance handles, connectors, and housings.

- Automotive: Door handles, bumpers, distributor disc covers, fenders, wheel covers, etc.

- Industrial Parts: Fans, keyboards, fishing reels, parts, lampshades, etc.

PBT is easy to process and can be injection molded or extruded. PBT products have specific requirements for surface finish and scratch resistance. There are many ways to enhance the surface smoothness of PBT injection-molded products, such as adding conventional lower molecular weight silicone/siloxane additives like silicone oil, silicone fluids, or ultra-high molecular weight silicone masterbatch (siloxane masterbatch).

However, In actual production and processing, many manufacturers have found that using low molecular weight silicone additives can result in PBT product defects, thus affecting quality. The following are common problems associated with using low molecular weight silicone additives:

- PBT products Insufficient Surface Smoothness:

Low molecular weight silicone additives have a high resin proportion and low silicone content. Although these additives are inexpensive, they often fail to meet surface effect requirements and generally need to be added in very high proportions to be effective. It is recommended to choose ultra-high molecular weight silicone additives to achieve excellent surface quality with minimal addition.

- PBT products Sticky Surfaces and Precipitation:

Adding too many low molecular weight silicone additives can cause them to migrate to the surface over time, resulting in precipitation. It is recommended to use ultra-high molecular weight silicone additives. Compared to conventional lower molecular weight silicone/siloxane additives like silicone oil, silicone fluids, or other processing aids, ultra-high molecular weight silicone masterbatch offers improved benefits, Companies like SILIKE offer SILIKE LYSI series Ultra-High Molecular Weight Silicone Masterbatch.

Enhancing Surface Smoothness in PBT Injection Products with SILIKE LYSI Series Ultra-High Molecular Weight Silicone Masterbatch

SILIKE LYSI series ultra-high molecular weight silicone masterbatch (siloxane masterbatch) is a pelletized formulation with ultra-high molecular weight siloxane polymer dispersed in various resin carriers. It is widely used as an efficient processing additive in compatible resin systems to improve processing properties and modify surface quality.

SILIKE LYSI-408 ultra-high molecular weight silicone masterbatch is a pelletized formulation with 30% ultra-high molecular weight siloxane polymer dispersed in polyester (PET). It is widely used as an efficient additive for PET and PBT-compatible resin systems to improve processing properties and surface quality.

Adding SILIKE ultra-high molecular weight silicone masterbatch (siloxane masterbatch) LYSI-408 to PBT in amounts of 0.2~1% can provide the following advantages:

- Improved processing and flow of the resin is expected..

- Better mold filling.

- Less extruder torque and internal lubricants.

- Easier mold release and faster throughput.

At higher addition levels (2~5%) of SILIKE ultra-high molecular weight silicone masterbatch, the following advantages can be achieved:

- Improved surface properties.

- Enhanced lubricity, slip, and lower coefficient of friction.

- Better wear and scratch resistance.

In fact, there are more questions about PBT injection molding products that are not listed here. If you have other questions about PBT injection molding products, you can consult SILIKE. We are a leading provider of modified plastic additives, offering innovative solutions to enhance the performance and functionality of plastic materials. With years of experience and expertise in the industry, we specialize in developing and manufacturing high-quality additives that improve the mechanical, thermal, and processing properties of plastics.

Contact us at Tel: +86-28-83625089 or via email: amy.wang@silike.cn. Visit our website: www.siliketech.com to learn more.

Post time: Jun-28-2024