How to solve the processing difficulties of flame retardants?

Flame retardants have a very large market size globally and are widely used in industries such as construction, automotive, electronics, aerospace, etc. According to the market research report, the flame retardants market has maintained a good growth trend in the past few years.

However, in the production process of flame retardants, the following processing difficulties are often faced:

Poor dispersion: Flame retardants usually exist in the form of particles or powders and have high density and specific gravity, which makes it difficult to be uniformly dispersed in the base material during processing. Poor dispersion will lead to uneven distribution of the flame retardant in the material, affecting the flame retardant effect.

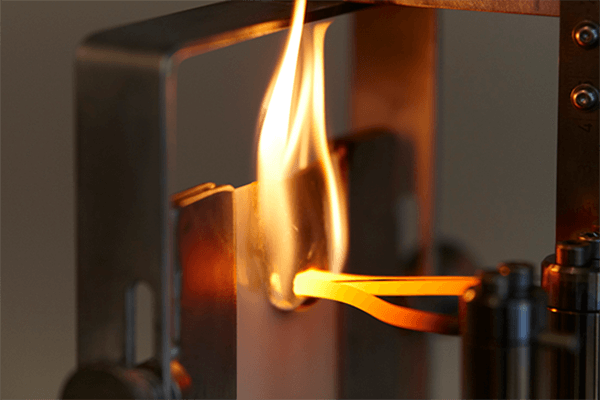

Poor thermal stability: Some flame retardants will decompose at high temperatures or when exposed to high temperatures for a long period of time, losing their flame retardant effect and even producing harmful substances. Therefore, it is necessary to control the heating temperature and processing time during processing to ensure the thermal stability of flame retardants.

Compatibility problems: There may be compatibility problems between the flame retardant and the base material, i.e. the affinity between the two is not strong enough to combine effectively. This will lead to poor dispersion of the flame retardant and unsatisfactory flame retardant performance.

Influence on material properties: Adding too much flame retardant may lead to a decrease in the mechanical and electrical properties of the material, and even cause embrittlement and deformation of the material. Therefore, it is necessary to reasonably control the amount of additive according to the specific material and the characteristics of the flame retardant in the process.

To overcome these machining difficulties, the following measures can be taken:

Selection of suitable processing method: According to the specific material and flame retardant properties, select the suitable processing method, such as extrusion, injection molding, compression molding and so on. Different processing methods have different effects on the dispersion, compatibility and thermal stability of flame retardants.

Control the amount of additive: Reasonably control the amount of flame retardant added, to avoid excessive use of flame retardants leading to a decline in the performance of the material.

Optimize the dispersibility of flame retardants: The use of dispersants or surface modifiers can improve the dispersibility of flame retardants and increase their homogeneity in the material.

Selection of suitable flame retardants: According to the specific application requirements, select suitable flame retardants, taking into account factors such as their thermal stability, compatibility and dispersibility.

SILIKE Hyperdispersants – Specially developed for the dispersion of flame retardants. This series of products is suitable for common thermoplastic resins, TPE, TPU and other thermoplastic elastomers. In addition to flame retardants, this series of products is also suitable for masterbatches or highly concentrated pre-dispersed materials.

- Good machining lubricity

- Improved processing efficiency

- Improved compatibility between powder and substrate

- No precipitation, improve surface smoothness

- Improved dispersion of flame retardant powder, synergistic flame retardancy

Post time: Sep-26-2023