In the plastic processing industry, die build-up is a common problem that can lead to surface defects in products, affecting product quality and production efficiency.

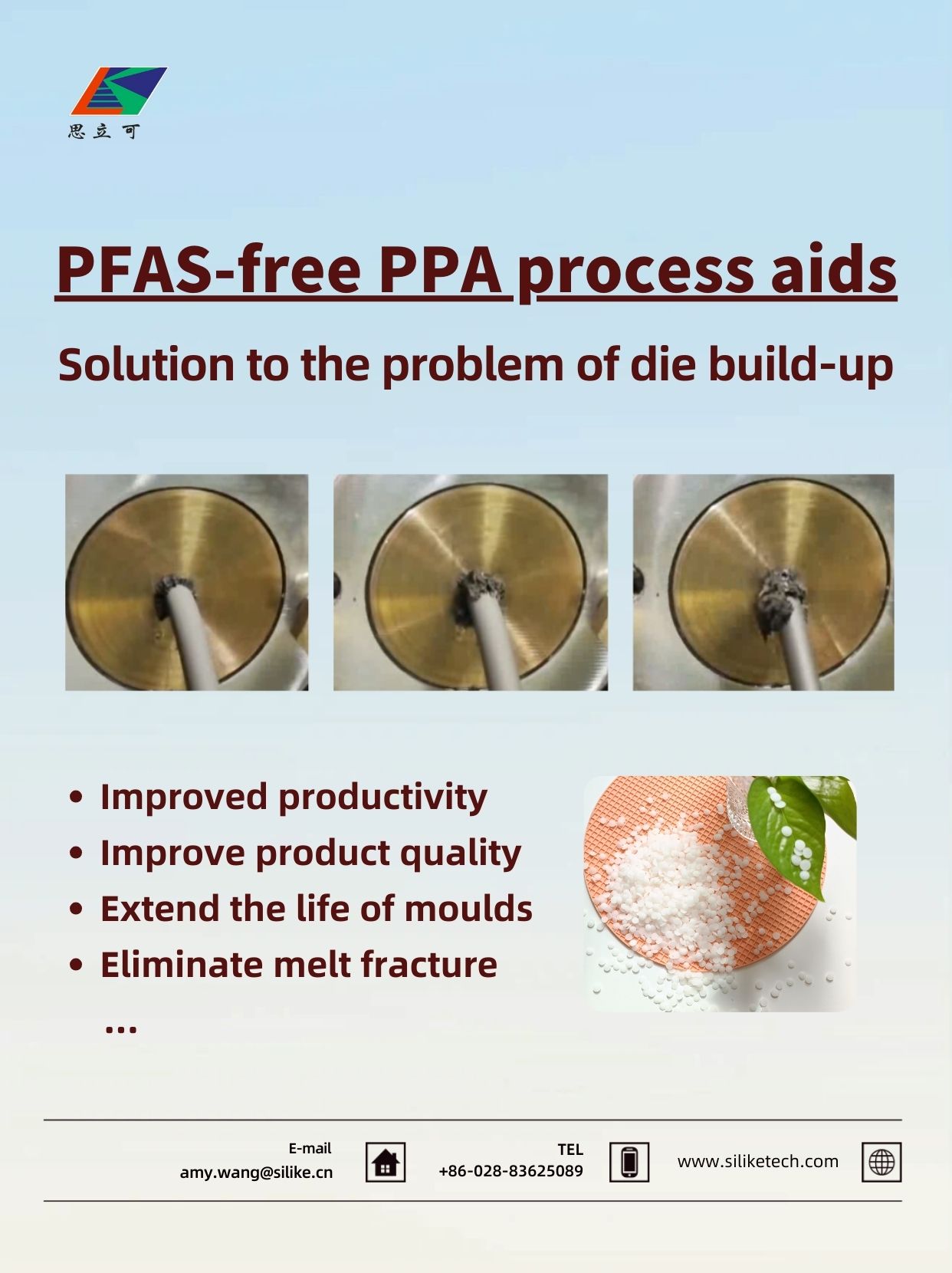

Die build-up refers to the accumulation of material at the outlet of the mold during plastic processing, forming deposits that are difficult to remove. This phenomenon usually occurs in injection molding, extrusion and other processes, especially in the processing of high viscosity and high melting point plastic materials. Accumulated material not only causes uneven and uneven surface of the product, but also may cause damage to the mold and increase production costs.

SILIKE PFAS-free PPA processing aids, as an effective additive, has shown significant effectiveness in solving this problem.

SILIKE PFAS-free PPA masterbatch is a PFAS-free polymer processing aid (PPA) introduced by SILIKE. The additive is an organically modified polysiloxane, which takes advantage of the excellent initial lubrication effect of polysiloxanes and the polar effect of the modified groups to migrate and act on the processing equipment during processing.

SILIKE PFAS-free PPA masterbatch can be a perfect substitute for fluorine-based PPA processing aids, and a small amount of addition can effectively improve resin flow, as well as lubricity and surface properties of plastic extrusion, eliminate melt breakage, improve the mouth and die build-up, and reduce the film surface crystals, improve yield and product quality, and at the same time, environmentally friendly and safe.

SILIKE PFAS-free PPA masterbatch has a wide range of applications and can be used in films, masterbatches, tubes, petrochemical industry, wires and cables, and so on.

Application advantages of SILIKE PFAS-free PPA processing aids:

1.Improved productivity: SILIKE PFAS-free PPA processing aids improves the processing flow of the resin, and good flow is key to reducing material build-up during plastics processing. Non-PFAS Process Aids reduces the melt viscosity of the resin, making it easier for the plastic to pass through the narrow part of the mould, thus reducing the formation of material build-up. This reduces downtime for cleaning up build-up and improves productivity.

2.Improve product quality: Adding PFAS-free Polymer Processing Aids in the right amount can eliminate melt fracture, reduce surface defects and enhance the overall appearance and performance of the product. PFAS-free PPA processing aids used in film preparation can also effectively reduce the film surface crystal points.

3.Extend the life of moulds: PFAS-Free Polymer Process Aid can reduce the wear and damage of moulds and extend the service life of processing equipment and moulds by virtue of its advantageous lubrication performance during plastic processing.

Manufacturers in the plastics industry, if you are looking for a functional lubricant for plastics processing, choose SILIKE PFAS-free PPA processing aids! We will customise an efficient and environmentally friendly solution for your plastics processing.

Chengdu SILIKE Technology Co., Ltd, a Chinese leading Silicone Additive Supplier for modified plastic, offer innovative solutions to enhance the performance and functionality of plastic materials. Welcome to contact us, SILIKE will provide you with efficient plastics processing solutions.

Contact us Tel: +86-28-83625089 or via email: amy.wang@silike.cn.

website: www.siliketech.com to learn more.

Post time: Nov-05-2024