How can help your TPE Wire Compound improve processing properties and hand feeling?

Most headset lines and data lines are made of TPE compound, the main formula is SEBS, PP, fillers, white oil, and granulate with other additives. Silicone has played a crucial role in it. Due to the payout speed of TPE wire being very fast, usually, about 100 – 300 m/s, and the diameter of the wire being very small, a vast shear force which is vertical to the wire direction will form at the dies and is easily caused melt fracture. How to solve this processing problem?

Many TPE compound makers have been raving about taking silicone additives to improve resin flow.

However, we must be noted that the effect is significantly different between the good and bad quality silicone masterbatch, the good one will leading a very nice dry surface finish of wire; the bad one might offer a particular surface smooth also, but with sticky.

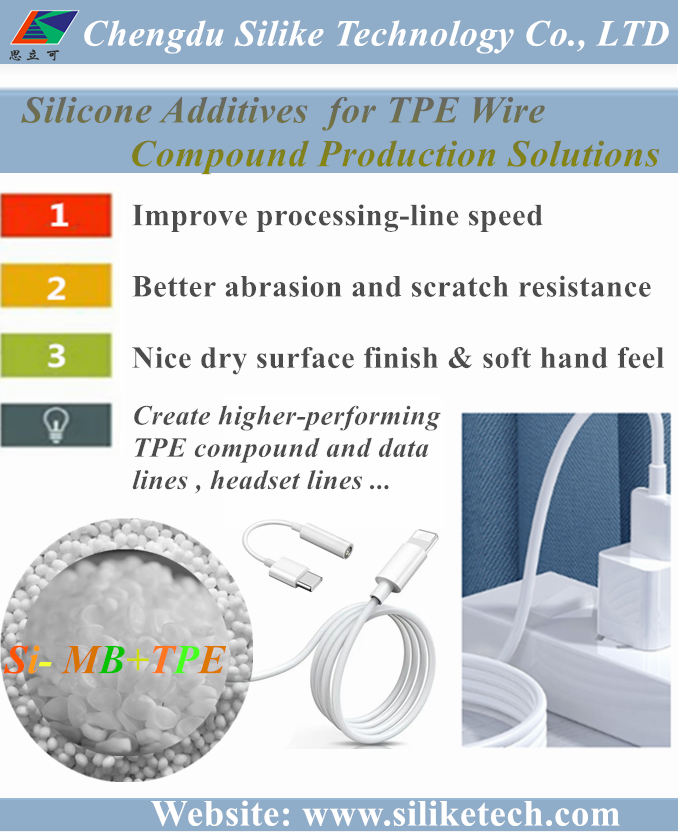

SILIKE Technology has been focusing on the application research of silicone in the polymer materials field to improve the processing performance and surface properties of materials for more than 20 years. Our silicone masterbatch solution for TPE wire compound, Creates higher-performing TPE compound and headset lines and data lines, achieving nice dry surface finishes, and soft hand feeling, with no worry about surface sticky issues.

Post time: Dec-08-2022