PC/ABS materials are more commonly used for lifting brackets for display devices and are also commonly used for automotive interiors.

Many components used in automotive instrument panels, center consoles, and trim are made from polycarbonate/acrylonitrile-butadiene-styrene (PC/ABS) blends. These materials are prone to squeaking, which is caused by friction and vibration when two parts move against each other (stick-slip action).

Currently, common solutions include covering soft rubber materials, coating lubricants on the surface, and using metal materials to replace the above materials. These methods can effectively reduce the friction noise of the material.

But the disadvantages are also obvious: the solution of covering the soft rubber material makes the cost of the whole product higher. The lubricant-coated solution causes the user to come into contact with the lubricant when using the product, which affects the user experience, and the improvement of the solution will get worse with time. The use of metal materials increases the overall weight of the product, which is not conducive to lightweight requirements.

SILIKE anti-squeak masterbatch, High-Performance Noise Reduction Additive

SILIKE anti-squeak masterbatch is a special polysiloxane that provides excellent permanent anti-squeaking performance for PC / ABS parts at a lower cost. Since the anti-squeaking particles are incorporated during the mixing or injection molding process, there is no need for post-processing steps that slow down the production speed.

SILIKE anti-squeak masterbatch SILIPLAS 2070 is currently used in two major industrial sectors: one is automotive interior parts. As people’s expectations of cars become higher and higher, and they want them to be quieter and quieter, this additive can better meet these needs. The second category is household appliances, as long as the use of PC / ABS household appliances, the addition of this additive can prevent the friction of the parts when the noise.

Typical advantages of SILIKE anti-squeak masterbatch SILIPLAS 2070

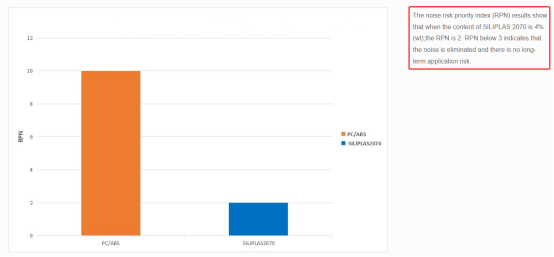

• Excellent noise reduction performance: RPN<3 (according to VDA 230-206)

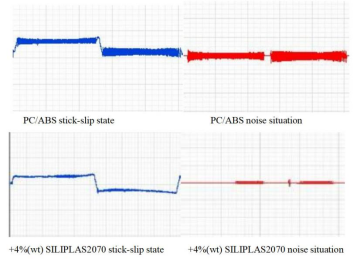

• Reduce stick-slip

• Instant, long-lasting noise reduction characteristics

• Low coefficient of friction (COF)

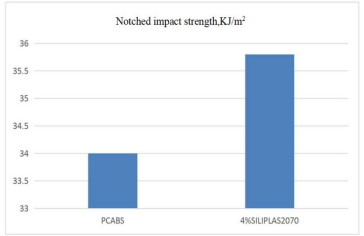

• Minimal impact on the key mechanical properties of PC / ABS (impact, modulus, strength, elongation)

• Effective performance with low addition amount (4wt%)

• Easy to handle, free flowing particles

The Usage and dosage of SILIKE anti-squeak masterbatch SILIPLAS 2070:

Added when the PC/ABS alloy is made, or after the PC/ABS alloy is made, and then melt-extrusion granulated, or it can be added directly and injection molded (under the premise of ensuring dispersion). The recommended addition amount is 3-8%, Specific ratios are adjusted according to actual needs.

In the past, due to post-processing, complex part design became difficult or impossible to achieve complete post-processing coverage. In contrast, silicone additives do not need to modify the design to optimize their anti-squeaking performance. SILIKE SILIPLAS 2070 is the first product in the new series of anti-noise silicone additives, suitable for automobiles, transportation, consumer, construction, and home appliances.

If you are looking for a high-performance noise reduction masterbatch or additive, we suggest you try SILIKE anti-squeak masterbatch, we believe that this series of additives will bring good noise reduction performance for your products. SILIKE’s anti-squeak masterbatch is suitable for application in all areas of daily life, such as household or automotive equipment, sanitary facilities, or engineering parts.

Way to prevent disturbing noise from plastic parts.

Contact us Tel: +86-28-83625089 or via email: amy.wang@silike.cn.

website:www.siliketech.com to learn more.

Post time: Jul-26-2024