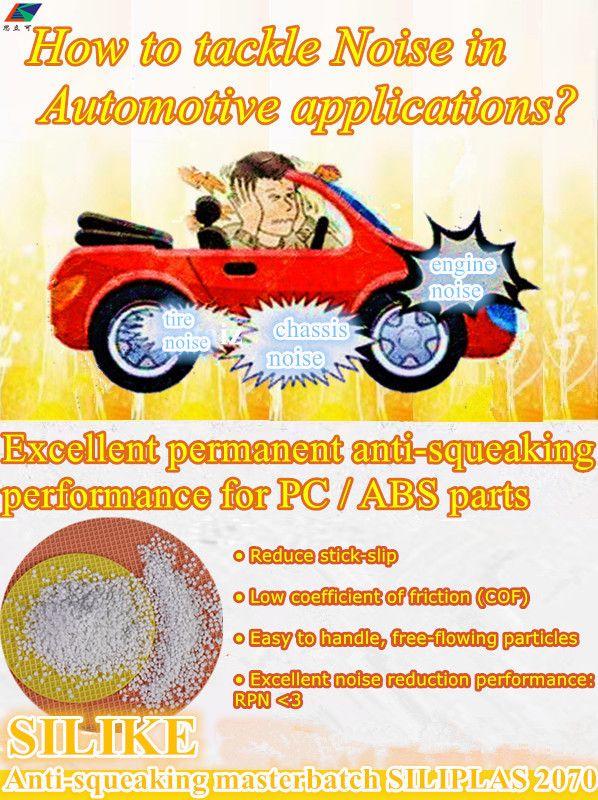

Way to tackle squeaking in automotive interior applications!! Noise minimization in automotive interiors is becoming increasingly important, to address this issue, Silike has developed an anti-squeaking masterbatch SILIPLAS 2070, Which is a special polysiloxane that provides excellent permanent anti-squeaking performance for PC / ABS parts at a reasonable cost. this novel technology can benefit automotive OEMs and transportation, consumer, construction, and home appliances industries.

How to use it?

When the anti-squeaking particles are incorporated during the mixing or injection molding process, there is no need for post-processing steps that slow down the production speed.

Key Benefits:

1. Low loading of 4 wt%, achieved an anti-squeak risk priority number (RPN <3 ), indicates that the material is not squeaking and does not present any risk for long-term squeaking issues.

2. Maintain the better mechanical properties of PC/ABS alloy-including its typical impact resistance.

3. By expanding design freedom. In the past, due to post-processing, complex part design became difficult or impossible to achieve complete post-processing

coverage. In contrast, SILIPLAS 2070 do not need to modify the design to optimize their anti-squeaking performance.

Post time: Nov-29-2021