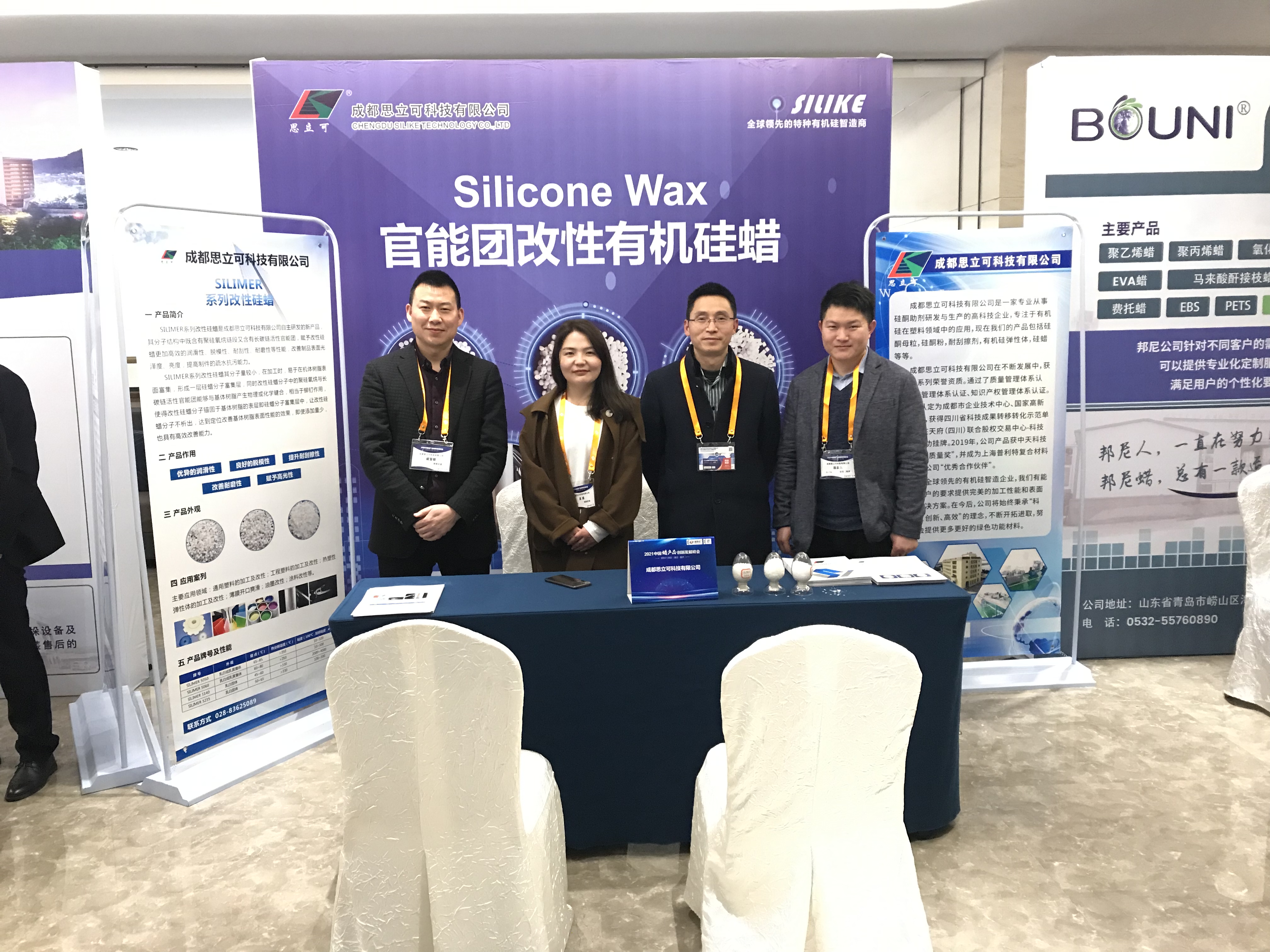

Chinese wax product innovation and development of a three-day summit is held in jiaxing, zhejiang province, and the summit participants are numerous. Based on the principle of mutual exchanges, common progress, Mr.Chen, R & D manager of Chengdu Silike Technology co., Ltd, attends the grand meeting together with our team and set up a booth in hall. In the meeting , Mr.Chen makes a speech on our modified silicone wax product.

Speech Content

In the communication , Mr. Chen mainly introduced the modified silicone wax products of our company in full detail from many perspectives, such as the innovation point, the working principle, the grade and typical performance, and the typical applications of silicone wax. Mr.Chen said the traditional PE wax has poor scratch resistance performance, lubrication performance is not efficient enough, and the application effect in engineering plastics is also not good. In order to solve this problem, Our R & D team overcomes many difficulties and finally successfully developed SILIMER series modified silicone wax products. Its molecular structure contains polysiloxane chain segment and the length of carbon chain reactive functional groups, which could make a better compatibility between modified silicone wax and the matrix resin, give modified silicone wax more efficient lubricity, better mold release performance, good scratch resistance and abrasion resistance, Improve the surface gloss and brightness of products, improve the hydrophobic & anti-fouling ability of parts.

Product introduction

Silike SILIMER series modified silicone wax products can be used in a wide range of fields, mainly in the following fields:

General plastics: improve processing fluidity, demoulding performance, scratch resistance property, abrasion resistance property, and hydrophobicity.

Engineering plastics: improve processing fluidity, demoulding performance, scratch resistance property, abrasion resistance property, hydrophobicity, and improve surface gloss.

Elastomer: improve demoulding performance, scratch resistance property, abrasion resistance property, and improve surface gloss.

Film: improve anti-blocking and smoothness, reduce surface COF.

Oil ink: improve scratch resistance property, abrasion resistance property, hydrophobicity.

Coating: improve surface scratch resistance property, abrasion resistance property, hydrophobicity, and improve gloss.

Moments

The following are the highlights of our speech at the summit:

Mr. Chen of our R & D dept. introduces modified silicone wax products at the meeting

Site of China wax product innovation and development summit

Chengdu SiLiKe Technology Co., Ltd. is a national high-tech enterprise which independently research and develop, manufacture and sell silicone functional materials. Our story, to be continued...

Post time: Mar-19-2021