According to data from iiMedia.com, the global market sales of major household appliances in 2006 were 387 million units, and reached 570 million units as of 2019; according to data from China Household Electrical Appliances Association, from January to September 2019, the overall retail market for kitchen appliances in China The volume reached 21.234 million units, a year-on-year increase of 9.07%, and the retail sales reached $20.9 billion.

With the gradual improvement of people's living standards, the demand for kitchen appliances is also steadily increasing. At the same time, the cleanness and beauty of the housing of kitchen appliances has become a demand that cannot be ignored. As one of the main materials in the housing of household appliances, plastic has a certain degree of water resistance, but its oil resistance,stain resistant, and scratch resistance are poor. When used as a kitchen appliance shell, it is easy to adhere to grease, smoke and other stains during daily use, and the plastic shell is easily rubbed during the scrubbing process, leaving many traces and affecting the appearance of the appliance.

Based on this problem, combined with market demand, SILIKE has developed a new generation of silicone wax product SILIMER 5235, which is used to solve the common problem of kitchen appliances.SILIMER 5235 is a functional group-containing long-chain alkyl-modified silicone wax. It effectively combines the characteristics of functional group-containing long-chain alkyl with silicone. It utilizes the high enrichment ability of silicone wax to the plastic surface to form a silicone wax. Effective silicone wax film layer, and the silicone wax structure has a long-chain alkyl group containing functional groups, so that the silicone wax can be anchored on the surface and has a good long-term effect, and achieves a better reduction of surface energy, hydrophobic and oleophobic , Scratch resistance and other effects.

Hydrophobic and oleophobic performance test

The contact angle test can well reflect the ability of the surface of the material to be phobic to liquid substances and become an important indicator for detecting hydrophobic and oleophobic: the higher the contact angle of water or oil, the better the hydrophobic or oil performance. The hydrophobic, oleophobic and stain resistant properties of the material can be judged by the contact angle. It can be seen from the contact angle test that SILIMER 5235 has good hydrophobic and oleophobic properties, and the more the amount added, the better hydrophobic and oleophobic properties of the material.

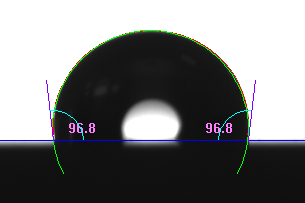

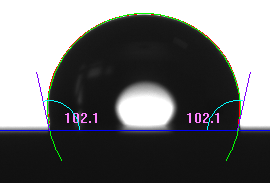

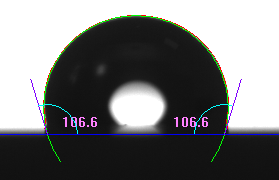

The following is a schematic diagram of the contact angle test comparison of deionized water:

PP

PP+4% 5235

PP+8% 5235

The contact angle test data is as follows:

|

sample |

Oil contact angle / ° |

Deionized water contact angle / ° |

|

PP |

25.3 |

96.8 |

|

PP+4%5235 |

41.7 |

102.1 |

|

PP+8%5235 |

46.9 |

106.6 |

Stain resistance test

Anti-fouling material does not mean that there will be no stains adhering to the surface of the material instead of reducing the adhesion of stains, and the stains can be easily wiped or cleaned by simple operations, so that the material has better stain resistance effect. Next, we will elaborate through several experimental tests.

In the laboratory, we use oil-based markers to write on the pure material to imitate the stains for a wipe test, and observe the residue after wiping. The following is the test video.

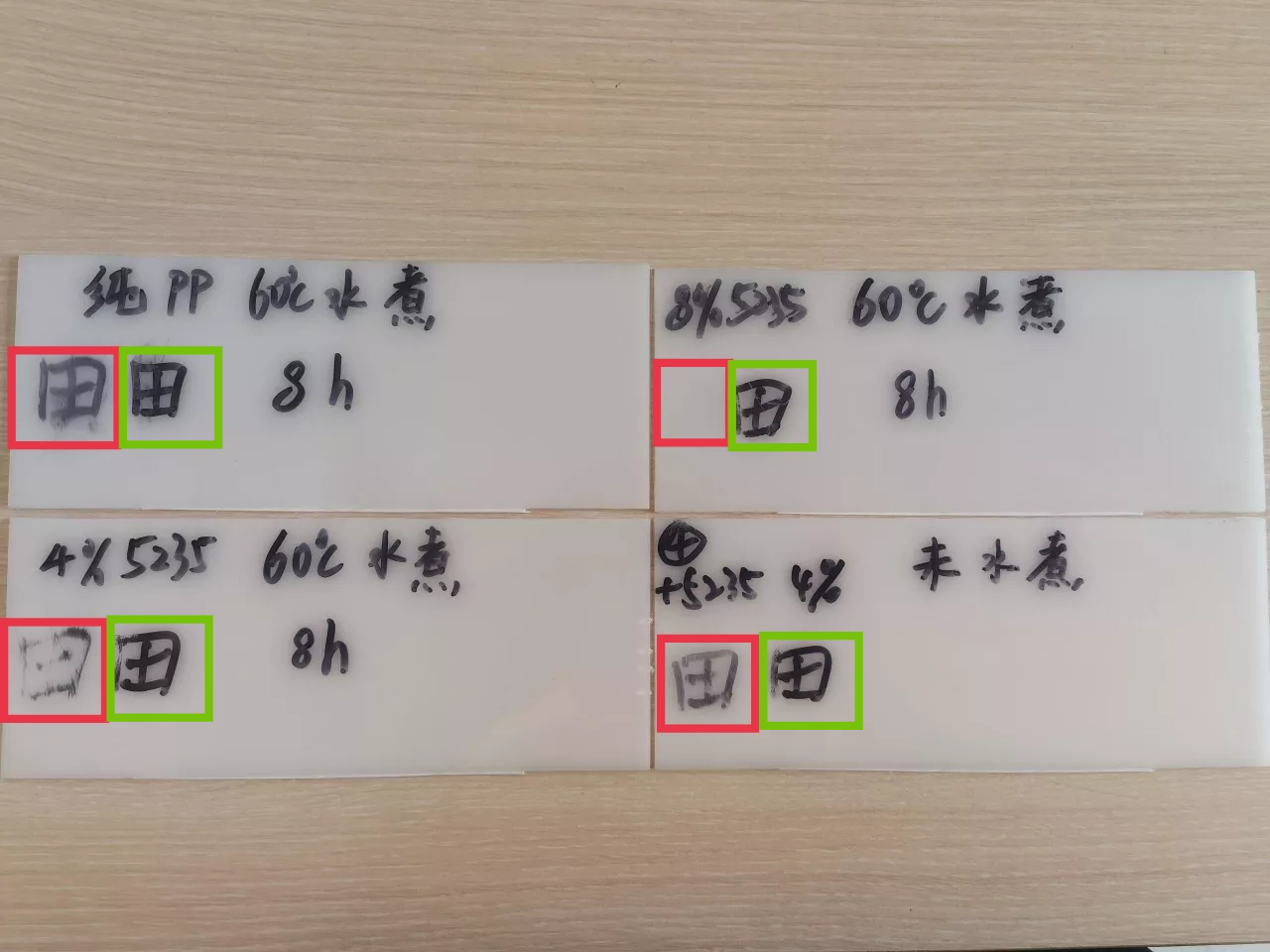

Kitchen appliances will encounter high temperature and high humidity during actual use. Therefore, we tested the samples through the 60℃ boiling experiment and found that the anti-fouling performance of the marker pen written on the sample board will not be reduced after boiling. To improve the effect, the following is the test picture.

Note: There are two "田" written on each sample board in the picture. The red box is the wiped effect, and the green box is the unwiped effect. It can be seen that the marker pen writes traces when the 5235 addition amount reaches 8% Completely wiped clean.

In addition, in the kitchen, we often encounter many condiments contacting kitchen appliances, and the adhesion of condiments can also show the anti-fouling performance of the material. In the laboratory, we use light soy sauce to investigate its spreading performance on the surface of the PP sample.

Based on the above experiments, we can make the conclusion of SILIMER 5235 has better hydrophobic, oleophobic and stain resistant properties, endows the material surface with better usability, and effectively prolongs the service life of the kitchen appliances.

Post time: Jul-05-2021