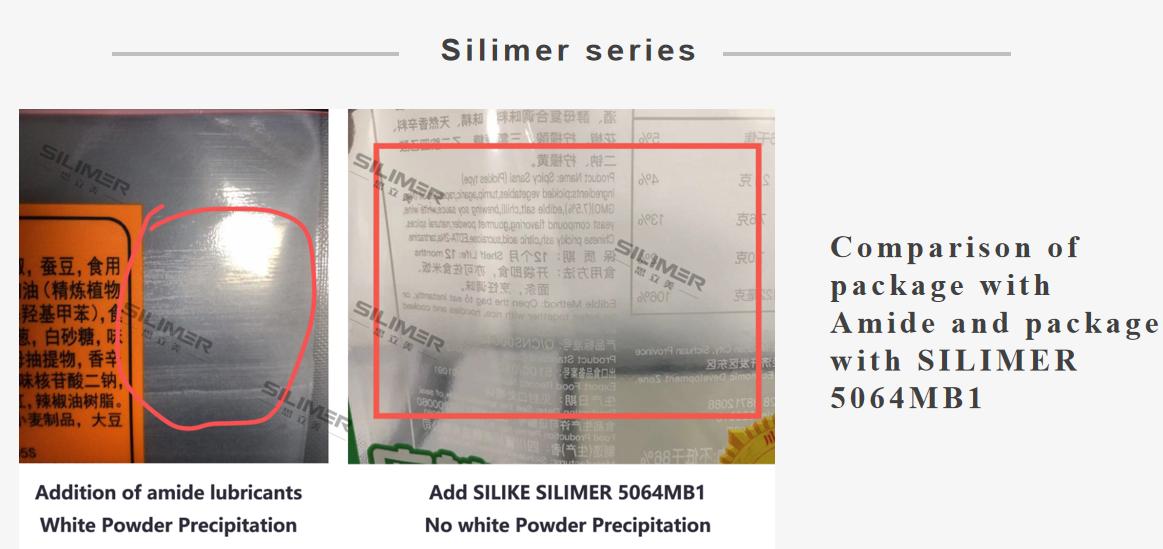

The white powder precipitating on the food packaging bag is because the slip agent (oleic acid amide, erucic acid amide) used by the film manufacturer itself precipitates, and the mechanism of the traditional amide slip agent is that the active ingredient migrates to the surface of the film, forming a single molecular lubricating layer and reducing the friction coefficient of the surface of the film. However, due to the small molecular weight of the amide slip agent, it is easy to precipitate or powder, so the powder is easy to remain on the composite roller during the film compounding process, and the powder on the rubber roller will be adhered to during the film processing, resulting in obvious white powder on the final product.

To solve the problem of easy precipitation of traditional amide slip agents, SILIKE has developed a modified co-polysiloxane product containing active organic functional groups – SILIMER series non-Blooming slip agent for plastic film. The working principle of this product is that the active functional groups on the long carbon chain can form a physical or chemical bond with the base resin, acting as an anchor to achieve easy migration without precipitation. The polysiloxane chain segments on the surface provide a slip effect. Recommended grades: SILIMER5064, SILIMER5064MB1,SILIMER5064MB2, SILIMER5065HB…

1.Benefits with SILIMER Series Non-Precipitation Slip Agent Masterbatch

- Deliver lasting slip performance over time and under high-temperature conditions

- Give the stable, low coefficient of friction, good anti-blocking, and better surface smoothness of the end product

- Not affect printing, heat sealing, composite, transparency, or haze

- Eliminates powder issues,safe and odor-free

- Widely used in BOPP/CPP/PE/PP films……

2.Some relevant performance test data

- Effectively reduce the friction coefficient, does not affect the haze and transmittance

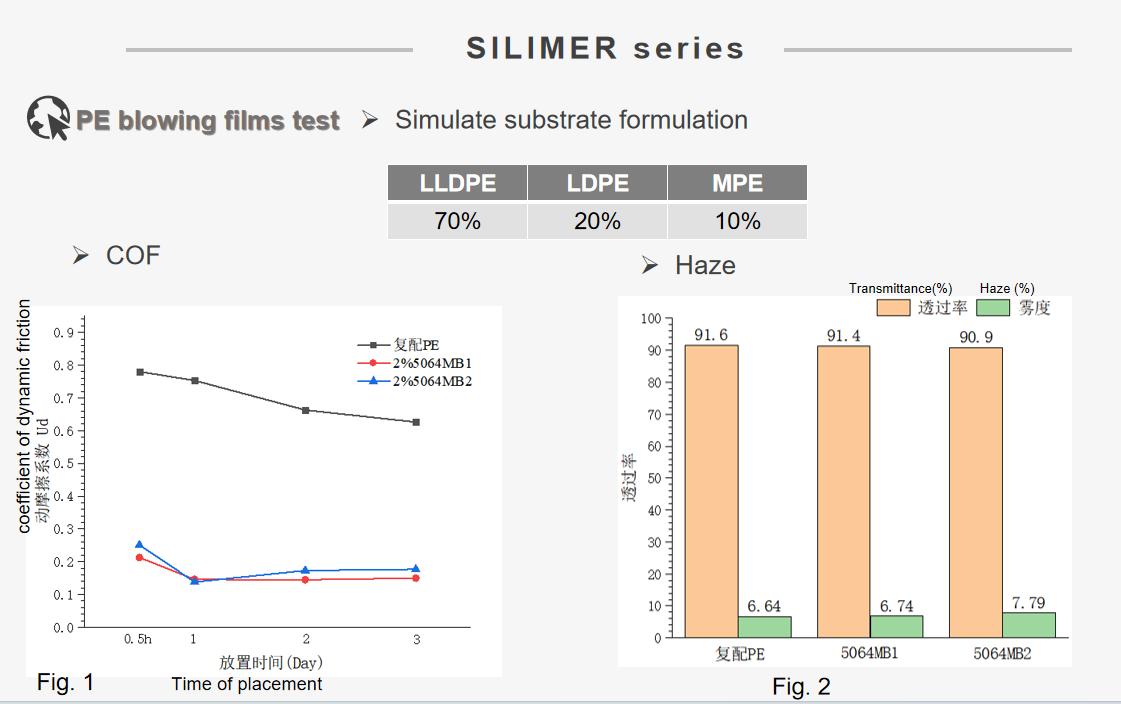

Simulated substrate formula: 70%LLDPE, 20%LDPE, 10% metallocene PE

As shown in Figure 1, the friction coefficient of the film after adding 2% SILIMER 5064MB1 and 2% SILIMER 5064MB2 was significantly reduced compared with the composite PE. Moreover, and as shown in Figure 2, the addition of SILIMER 5064MB1 and SILIMER 5064MB2 did not affect the haze and transmittance of the film.

- The friction coefficient is stable

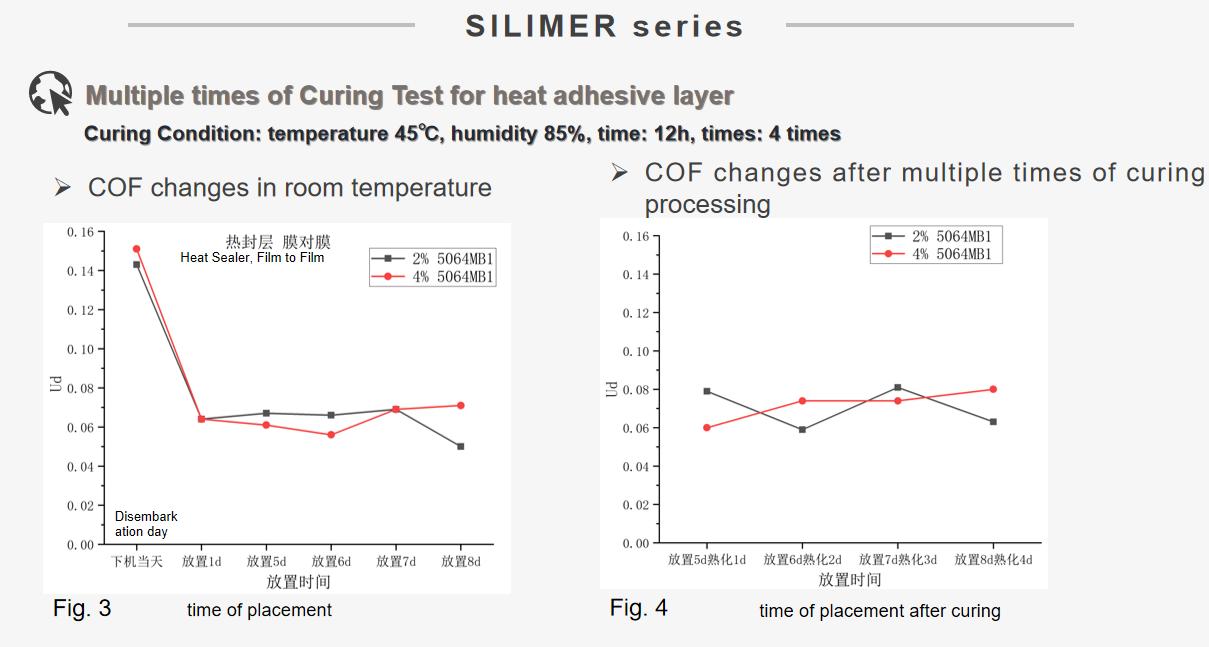

Curing conditions: temperature 45℃, humidity 85%, time 12h, 4 times

As shown in FIG. 3 and FIG. 4, it can be seen that the friction coefficient of the film after adding 2% SILIMER 5064MB1 and 4% SILIMER 5064MB1 remains at a relatively stable value after multiple curing.

- The surface of the film does not precipitate and does not affect the quality of the equipment and the final product

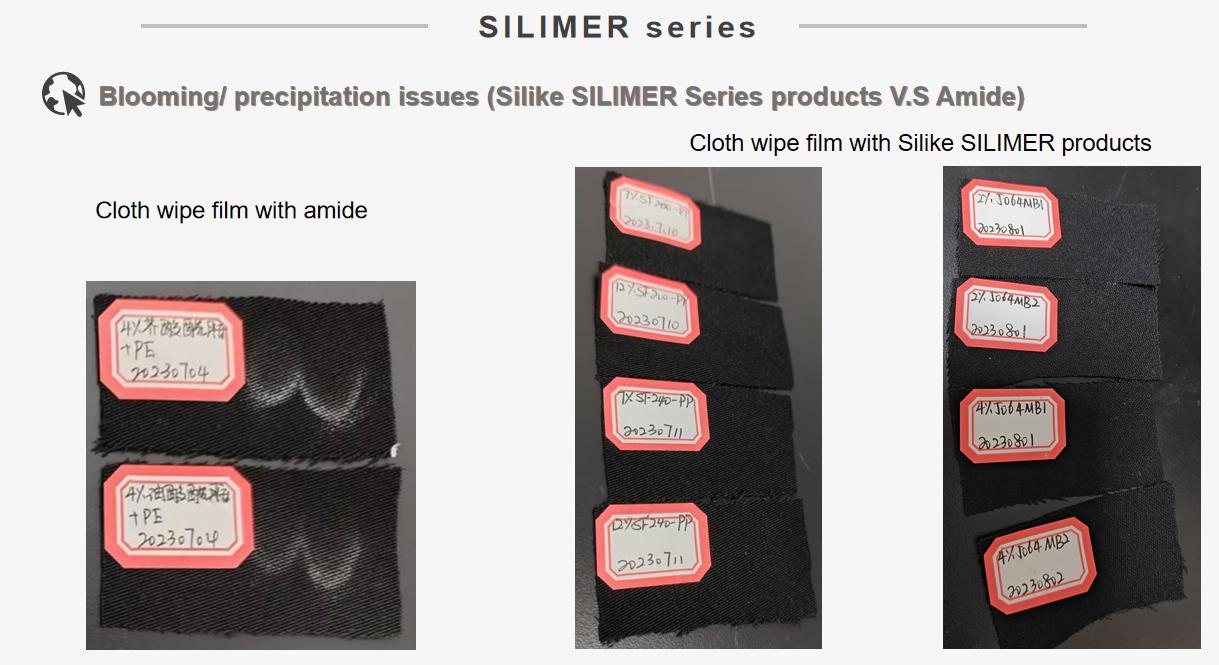

As shown in the figure below, use black cloth to wipe the surface of the film with amide and SILIMER product. It can be seen that compared with the use of amide additives, SILIMER series does not precipitate adn has no any precipitating powder.

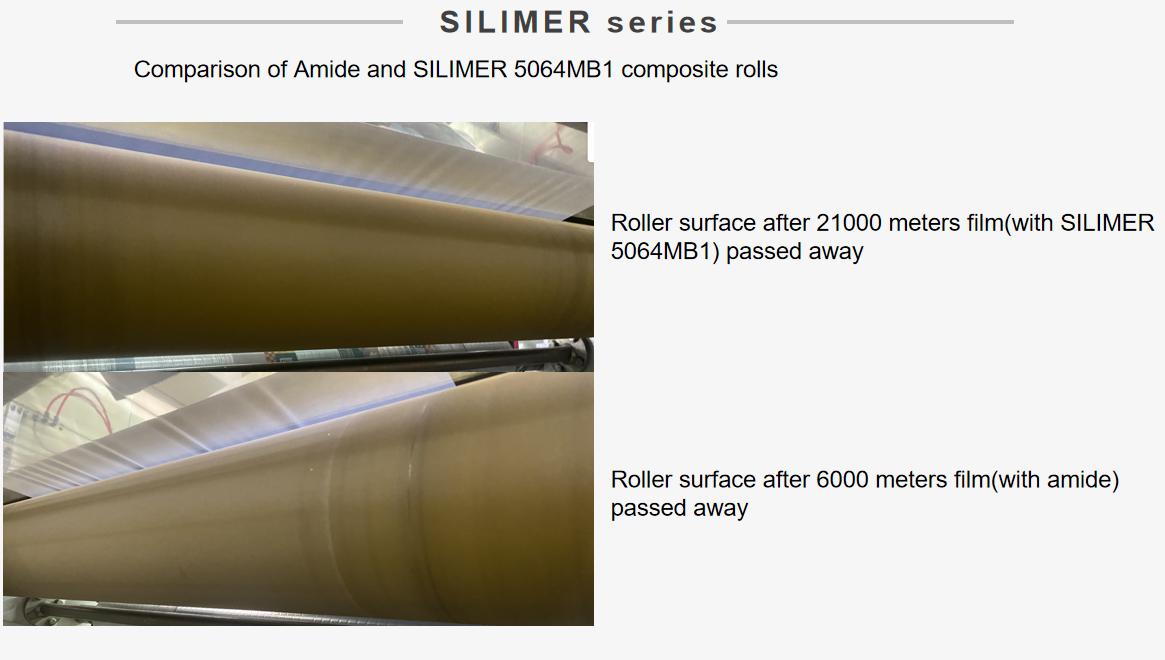

- Solve the problem of white powder in the composite roller and the final product bag

As shown in the figure below, after the composite roller passes 6000 meters of the film with erucic acid amide, there is obvious accumulation of white powder, and there is also obvious white powder on the final product bag; However, used with SILIMER series we can see when the composite roller passed 21000 meters, and the final product bag was clean and fresh.

3.The Power of SILIKE SILIMER series non-migrating Permanent slip Additive For Flexible Packaging.

Transform Your Food Packaging Safety! Tired of White Powder Precipitation in Your Composite Packaging Bags or other films? Ready for a Change? SILIKE SILIMER series non-migrating Permanent slip Additive For Flexible Packaging,non-Blooming slip agent,non-precipitation slip agent masterbatch for plastic film, eliminates powder issues, ensuring a flawless and clean packaging experience. Contact us now! Let’s revolutionize your packaging experience together!

We’re here to craft tailor-made solutions just for you! SILIKE SILIMER series non-precipitation slip agent masterbatch suitable in various plastic applications, not limited to packaging films (BOPP, CPP, BOPET, EVA, TPU film, LDPE, and LLDPE films.) also delivers stable, permanent slip solutions for sheets and other polymer products where slip and improved surface properties are desired.

Post time: Jan-19-2024