Thermoplastic Polyurethane (TPU) films are renowned for their exceptional flexibility, durability, and high-performance characteristics, making them a preferred choice across industries like automotive, medical, fashion, and consumer electronics. While standard TPU films are valued for their abrasion resistance and chemical stability, matte TPU films are gaining significant traction due to their aesthetic appeal, reduced glare, and fingerprint-resistant surfaces.

However, achieving a consistent and high-quality matte finish on TPU films can be challenging. Issues such as uneven texture, poor light diffusion, and surface defects often plague manufacturers. This article explores proven preparation methods for matte TPU films, addressing key challenges and offering actionable solutions to help you produce flawless products.

Preparation Methods for Matte TPU Film

1. Resin Selection and Additives: The Foundation of Matte TPU Films

The journey to creating high-quality matte TPU films begins with selecting the right materials.

1.1 TPU Resin

Choosing the appropriate TPU resin is critical. Key considerations include:

Hardness: Medium-hard to hard resins are ideal for maintaining surface integrity while ensuring flexibility.

Elasticity: Higher elasticity is essential for applications requiring bending or stretching, such as automotive interiors or footwear.

Processing Compatibility: Ensure the resin is compatible with your chosen processing method (extrusion, calendering, etc.).

1.2 Matting Agents

The most efficient and widely used method for producing matte TPU film is blending TPU with specific additives that reduce gloss and give it a matte finish. These additives, often referred to as matting agents ,mattifiers, or non-glossy TPU additive, are incorporated into the TPU during the compounding process. The matt flatting additives work by disrupting the smooth surface of the film, leading to light scattering and resulting in a matte appearance. Common types of matting agents include:

Silica-based Matting Agents: These fine silica particles disrupt the smoothness of the surface, creating a rough texture that scatters lights.

Polymeric Matting Agents: These agents are typically more uniform and offer better dispersion in the TPU matrix.

Calcium Carbonate: While not as commonly used as silica or polymeric agents, it can be used in some formulations for a matte finish.

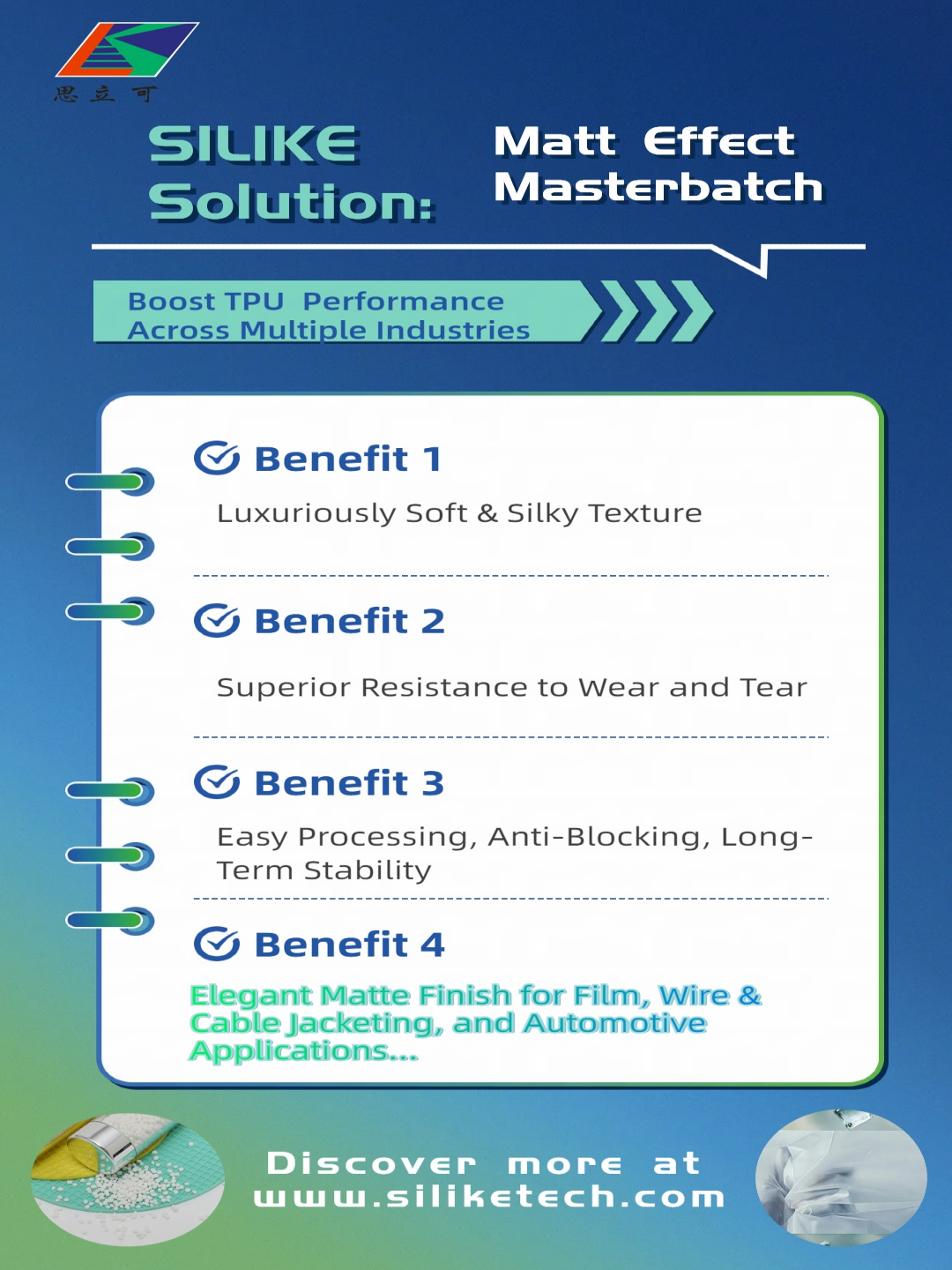

Pro Tip: Enhance Durability and Matte Appeal: SILIKE’s TPU based Masterbatch Solutions

Matt Effect Masterbatch is an innovative Matting Agent developed by SILIKE, utilizing thermoplastic polyurethane (TPU) as its carrier. Compatible with both polyester-based and polyether-based TPU, this matting agent is designed to enhance the matte appearance, surface touch, durability, and anti-blocking properties of TPU films and their final products.

The highlight of SILIKE’s Polyester TPU-based and Polyether TPU-based Matt Effect Masterbatch lies in its convenience—it can be directly incorporated during processing, eliminating the need for granulation, and ensures no risk of precipitation even with long-term use.

It is perfect for applications requiring premium matte finishes, such as TPU films used in packaging, automotive, footwear, medical devices, and consumer electronics.

Especially, Matt Effect Masterbatch 3235 is ideal for creating the best polyester TPU matte finish for packaging applications.

1.3 Additional Additives

To further enhance performance, consider incorporating:

Anti-blocking Agents Prevent films from sticking together during storage.

UV Stabilizers: Protect against UV degradation, ideal for outdoor applications.

Slip Agents: Improve surface slip properties for easier handling.

2. Extrusion Process: Precision is Key

Extrusion is the most common method for producing TPU films. To achieve a flawless matte finish:

2.1 Twin-Screw Extruder

A twin-screw extruder ensures better mixing and dispersion of matting agents, resulting in a uniform matte appearance.

2.2 Temperature Control

Maintain precise temperature control to avoid surface defects like bubbles, streaks, or uneven gloss.

2.3 Die Design

Use a flat die with a matte surface finish or incorporate a textured chill roll to impart the desired surface texture.

3. Surface Treatment Techniques: Enhancing the Matte Effect

Surface treatments can further refine the matte finish and improve functionality:

3.1 Coating

Apply a matte coating using roll or spray coating techniques to enhance the surface texture without altering the TPU composition.

3.2 Embossing

Pass the film through embossing rollers with a matte texture to create a raised pattern for a consistent finish.

3.3 Chemical Etching

Use mild chemical treatments to modify surface roughness, achieving a uniform matte texture for high-precision applications.

4. Blown Film vs. Cast Film Process: Choosing the Right Method

The choice between blown and cast film processes depends on your desired film properties:

4.1 Blown Film Process

Ideal for thicker films, the blown film process uses air cooling to achieve a natural matte finish.

4.2 Cast Film Process

Best for thinner films, the cast film process uses a textured chill roll to create a consistent and high-quality matte finish.

5. Post-Processing Techniques: Perfecting the Finish

Post-processing can refine the matte effect and enhance film performance:

5.1 Calendering

Pass the film through calendering rollers to adjust surface texture and thickness, ensuring a uniform matte finish.

5.2 Lamination

Bond the matte TPU film with other materials to enhance strength, durability, or barrier properties while preserving the matte appearance.

5.3 Surface Sanding

Use mechanical abrasion to refine the matte texture, creating a consistent surface finish for high-end applications.

A Guide to Matte TPU Films: SILIKE’s Matt Effect Masterbatch Delivers

SILIKE’s Matt Effect Masterbatch offers a reliable and efficient solution for producing high-quality matte TPU films. With easy incorporation during processing and long-term stability, it’s the perfect choice for manufacturers seeking to elevate their products.

Struggling with TPU Film Gloss? Or, ready to Achieve Premium Matte Finishes for Your TPU Film Production?

Contact SILIKE—the professional Matte Effect Masterbatch manufacturer— to learn more about innovative TPU Matt Effect Masterbatch solutions and request a sample of our Anti-blocking Matte Effect Additives!

Tel: +86-28-83625089, Email: amy.wang@silike.cn, Website: www.siliketech.com

Post time: Mar-05-2025