The materials of plastic clothing bag film mainly include the following, and their respective advantages and defects are as follows:

1.PE (polyethylene) :

Advantages: good toughness, not afraid of tearing, tensile resistance, bearing force, wear resistance, not easy to break, healthy and assured, food available, good sealing.

Defects: Low transparency, high fog, relatively high price.

2. PP (Polypropylene) :

Advantages: high transparency, sealed moisture-proof, no fear of oxidation, can be used repeatedly.

Defect: Tension is not very good, easy to break.

3. OPP (Oriented polypropylene) material:

Advantages: high transparency, good sealing.

Defects: tension is not enough, easy to break, and printing is the most easy to decolorize.

4.PVC (polyvinyl chloride) :

Advantages: safety and health, durable and beautiful and practical, exquisite shape, diverse styles.

Defects: relatively poor environmental protection, containing chlorine, combustion will produce harmful gases.

The plastic clothing bag film of the above materials has its own characteristics, and the choice can be based on specific needs and considering cost, environmental protection and other factors to decide which material to use. Garment bag is a product of the “coat”, in addition to packaging decoration, the most important thing is to play an independent packaging, storage, protection and so on. The more delicate the clothing, the more need the protection of the packaging bag, to avoid the clothing in the storage and transportation process of damage or contact with dust and other dirty.

Therefore, clothing bags are indispensable in the clothing industry. However, the clothing packaging film is easy to appear in the use and transportation process: the friction coefficient of the clothing bag is unstable, the powder precipitation soiled the clothes and other problems.

SILIMER non-Blooming slip additives, Solve the problem of powder migration from clothing bag film

The development of SILIKE SILIMER’s non-migratory super slip additives is an innovation in garment bag film. Different from traditional low-molecular-weight smoothing agent, SILIMER non-Blooming slip agent is a new modified copolymerized polysiloxane product. Its molecules contain both polysiloxane chain segments and active groups with long carbon chains. Long carbon chains are compatible with resins to play an anchoring role, and silicon chains segreate to the surface of the film to play a smoothing role. So that it can play a smooth role without completely precipitation, from the root to solve the problem of clothing bag film powder precipitation pollution clothing.

The following are the advantages of SILIKE SILIMER’s non-precipitation slip agent masterbatch in the application of clothing bag film:

Long-lasting smooth, no precipitation powder: significantly improve the smoothness, reduce the dynamic and static friction coefficient, durable smooth without precipitation, to avoid the contamination of clothing caused by precipitation powder.

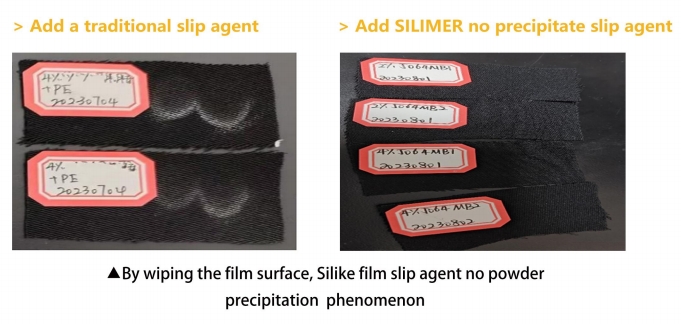

As shown in the figure below, the surface of the film with traditional low molecular smoothing agent and the surface with SILIKE SILIMER non-Blooming slip agent were wiped with black cloth. It can be seen that compared with the use of traditional low molecular additives, SILIKE SILIMER Non-Migratory Slip Additives does not precipitate powder phenomenon.

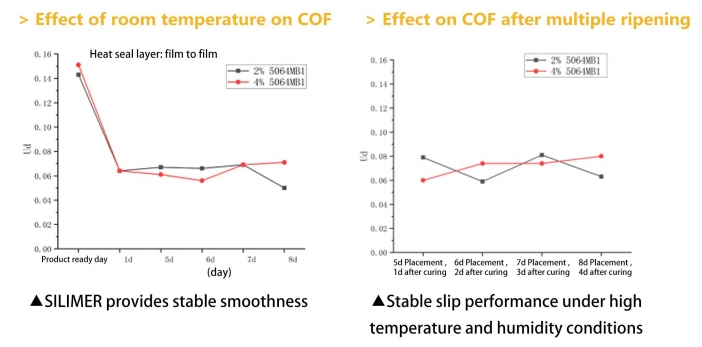

High temperature resistance, stable friction coefficient: good high temperature resistance, excellent compatibility with the matrix resin, will not be caused by high temperature storage, transportation or temperature changes, such as non-smooth, unstable friction coefficient and other conditions.

As shown below, curing conditions: temperature 45℃, humidity 85%, time 12h, 4 times.

The product has COF stability after many times of high temperature and high humidity environment treatment, the film is prepared for the customer, five layers of blown film, the thickness of 100 microns. It can be seen that after the use of SILIKE SILIMER non-migratory super slip additives, the film has good high temperature resistance and stable friction coefficient.

Low haze: does not affect the use of scenes that require transparency.

High stability: does not affect printing, composite and other subsequent processing.

Widely used: can be used in BOPP, CPP, PE, PP and other films.

Improve the processing performance and surface properties of the film, provide long-term high temperature smoothness, avoid precipitation powder, we have rich experience and many successful cases, if you are looking for related material modification solutions, please contact SILIKE!

Chengdu SILIKE Technology Co., Ltd, a Chinese leading Silicone Additive Supplier for modified plastic, offer innovative solutions to enhance the performance and functionality of plastic materials. Welcome to contact us, SILIKE will provide you with efficient plastics processing solutions.

Contact us Tel: +86-28-83625089 or via email: amy.wang@silike.cn.

website: www.siliketech.com to learn more.

Post time: Nov-05-2024