In today’s highly competitive automotive market, the pursuit of perfection extends far beyond just engine performance and sleek designs. One crucial aspect that has been garnering increasing attention is the durability and aesthetics of automotive interiors and exteriors, which is where scratch-resistant agents and silicone masterbatches come into play.

The Indispensable Need for Anti-scratch additive in the Automotive Sector

Automobiles are constantly exposed to a myriad of potential scratching hazards. From the daily grind of car washes, where abrasive sponges and brushes can mar the surface, to the inevitable encounters with keys, zippers, and other sharp objects in parking lots or during loading and unloading. Consumers invest a significant amount of money in their vehicles and expect them to maintain their showroom shine for years.

As a processing aid, the anti-scratch agent can effectively prevent ugly scratches and significantly improve the Automotive scratch resistance by improving the surface hardness and wear resistance of polypropylene (pp) automotive materials.

Why does the automotive industry interior materials need to widely use scratch resistant agents?

Polypropylene (PP) surface hardness is low and scratch resistance is poor, so very small stress can form scratches on the surface of the material, these scratches both destroy the appearance of the product, but also easily lead to stress concentration, resulting in product strength reduction and shortened service life. So in order to improve this kind of issue, adding scratch resistance agent is a good solution in the automotive interior materials.

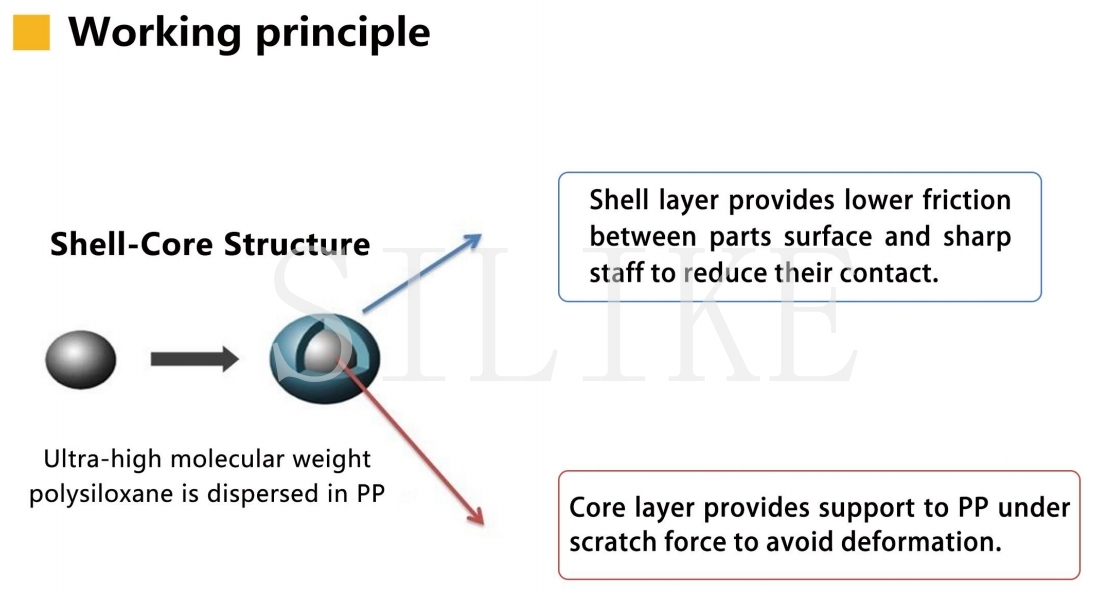

SILIKE scratch resistant masterbatch is a kind of silicone processing aid dispersed in PP with ultra-high molecular weight polysiloxane, and its principle of action is similar to the core-shell structure: SILIKE scratch resistant masterbatch reduces the friction coefficient of the shell layer of the product, reduces the friction between the surface of the part and sharp objects, thereby improving the surface scratch resistance of the product; The core layer provides support for PP under the scratch force to avoid deformation and to improve the scratch resistance of the product greatly.

As the automotive industry hurtles forward, embracing these high performance materials and additives is not an option but a necessity. Anti-Scratch Masterbatch is one of the efficient solutions to improve the scratch resistance of the surface of automotive interior materials, Stay tuned as further advancements in this field continue to transform the way we drive and experience our vehicles.

Chengdu SILIKE Technology Co., Ltd, a Chinese leading Silicone Additive Supplier for modified plastic, offer innovative solutions to enhance the performance and functionality of plastic materials. Welcome to contact us, SILIKE will provide you with efficient plastics processing solutions.

Contact us Tel: +86-28-83625089 or via email: amy.wang@silike.cn.

website: www.siliketech.com to learn more.

Post time: Jan-03-2025