White powder precipitation on composite film packaging bags is a recurring issue that plagues manufacturers globally. This unsightly problem not only diminishes the aesthetic appeal of your product but also raises serious concerns about quality and hygiene, particularly in industries like food, pharmaceuticals, and cosmetics. In this article, we explore the root causes of white powder precipitation, its impact on production, and introduce SILIKE’s SILIMER Series Super Slip Masterbatch— film contamination solutions that eliminate powder issues while enhancing film performance.

The Challenge: What Causes White Powder Precipitation?

The white powder commonly seen on composite film packaging bags is the result of slip agents—such as oleic acid amide and erucic acid amide—migrating to the surface. Traditional slip agents work by forming a molecular lubricating layer that reduces the friction coefficient of the film. However, their small molecular weight makes them prone to precipitation, leading to the formation of visible white powder.

This phenomenon creates a domino effect of issues:

1. Composite Roller Contamination: During the compounding process, white powder can accumulate on the composite rollers. This buildup can interfere with the smooth operation of your machinery, leading to processing inefficiencies and potential defects in the final film.

2. Rubber Roller Adhesion: As the film continues to be processed, the powder can transfer to the rubber rollers, leading to adhesion issues. This not only affects the processing equipment but also leads to powder transfer onto the final product, compromising its visual appeal.

3. Quality and Hygiene Concerns: The presence of white powder on packaging bags raises serious concerns regarding product cleanliness, particularly in industries where hygiene is paramount. It may lead to the perception of lower product quality and may even violate hygiene standards in regulated sectors like food packaging.

These challenges not only increase production costs but also result in customer dissatisfaction, making it imperative to find a reliable solution.

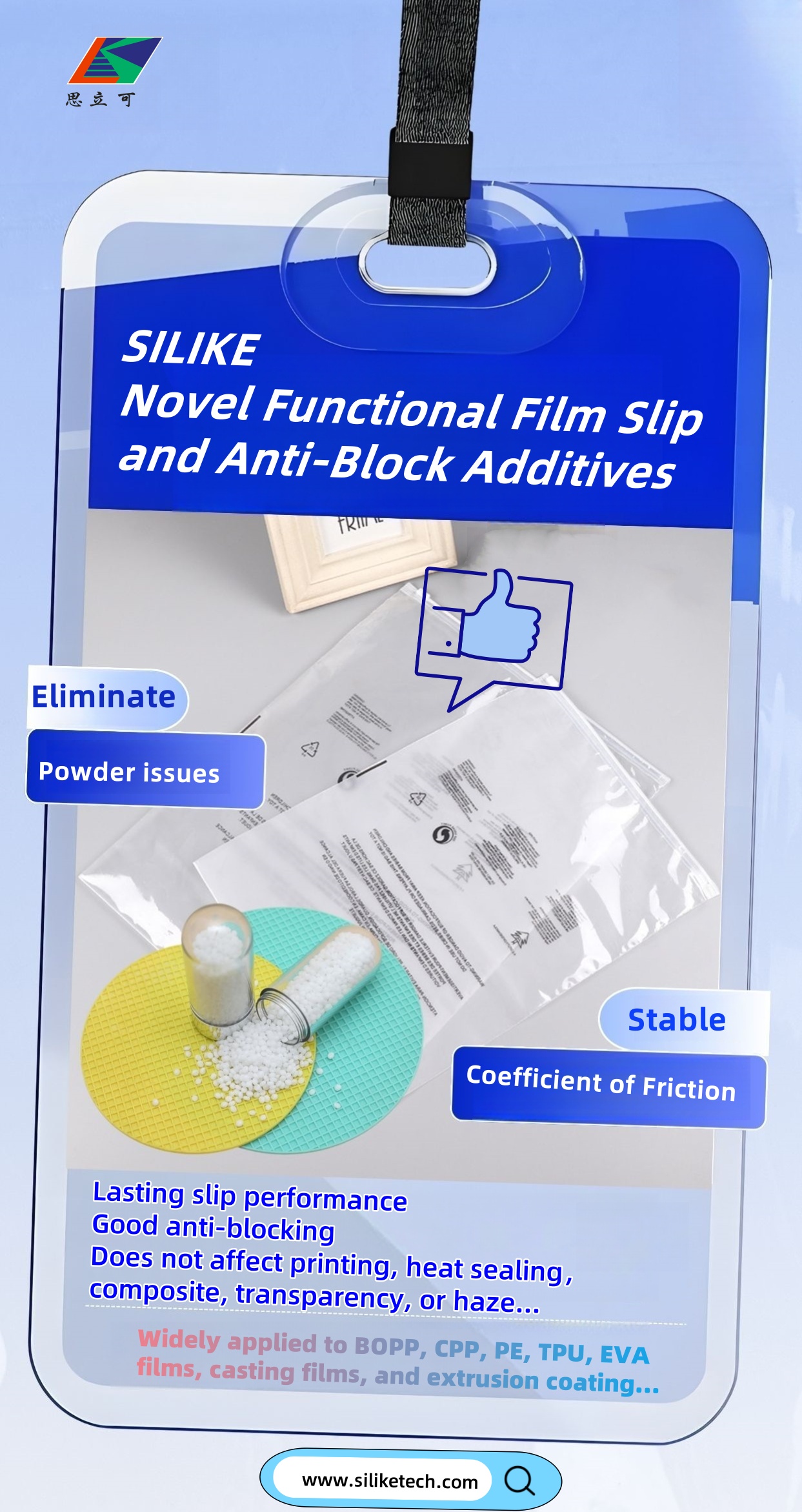

The Solution: SILIKE SILIMER Series Super Slip & Anti-Blocking Masterbatch – The Key to Cleaner, Higher-Quality Packaging

Innovate Beyond Traditional Slip Additives

At SILIKE, we understand the challenges faced by composite film manufacturers. That’s why we developed the SILIMER Series Super Slip Masterbatch—a non-migrating slip solution designed to eliminate powder precipitation while delivering unmatched performance as a functional film slip and anti-block additive.

Key Benefits of SILIKE SILIMER series super slip and anti-blocking additives

1. Eliminates Powder Issues: Our advanced formulation prevents slip agent migration, solves the white powder’s easy precipitation.

2. Lasting Slip Performance: Maintains a stable, low coefficient of friction throughout the film’s lifecycle.

3. Superior Anti-Blocking: Enhances film handling and prevents layers from sticking together.

4. Improved Surface Smoothness: Delivers a sleek, professional finish for premium packaging.

5. No Compromise on Film Properties: Does not affect printing, heat sealing, composite, transparency, or haze.

6. Safe and Odor-Free: Compliant with global regulatory standards, making it ideal for food and pharmaceutical packaging.

The SILIMER Series functional film additives are versatile and suitable for various plastic applications, including:BOPP, CPP, PE, and PP films,Packaging films and sheets, Polymer products requiring enhanced slip and surface properties.

SILIKE is a trusted leader in functional additives and masterbatch solutions for plastic films, with a proven track record of innovation and customer satisfaction. Our SILIMER Series Non-Migrating Slip & Anti-Block Additives are the result of extensive R&D, tailored to meet the specific needs of composite film manufacturers. Say goodbye to white powder precipitation in composite film packaging bags.

Visit www.siliketech.com to learn more about SILIKE’s SILIMER Series—your effective solution for functional film additives, offering a smoother and cleaner finish for your composite packaging films!

Post time: Mar-26-2025