Silicone masterbatch is a kind of additive in the rubber and plastic industry. The advanced technology in the field of silicone additives is the use of ultra-high molecular weight (UHMW) silicone polymer (PDMS) in various thermoplastic resins, such as LDPE, EVA, TPEE, HDPE, ABS, PP, PA6, PET, TPU, HIPS, POM, LLDPE, PC, SAN, etc. And as pellets so as to allow easy addition of the additive directly to the thermoplastic during processing. combining excellent processing with an affordable cost. The silicone masterbatch is easy to feed, or mix, into plastics during compounding, extrusion, or injection molding. It is better than traditional wax oil and other additives in improving slippage during production. Thus, plastic processors prefer to use them in the output.

Roles of Silicone Masterbatch additive in Improving Plastic Processing

The silicone masterbatch is one of the most popular choices for processors in plastic processing and surface quality improvements. As a kind of super lubricant. It has the following main functions when used in thermoplastic resin:

A. Improve the flow of resin and processing;

Better mold filling and mold release properties

Reduce the extrude torque and improve the extrusion rate;

B. Improves resin’s surface properties

Improve the plastic surface finish, smooth degree, and reduce the skin friction coefficient, Improve the wear resistance and scratch resistance;

And silicone masterbatch has good thermal stability (thermal decomposition temperature is about 430 ℃ in nitrogen ) and non-migration;

Environmental protection;

Safety contact with the food.

We must point out that all the silicone masterbatches functions are owned to A and B (the above two points we listed) but they are not two independent points but

supplement each other, and are closely related.

Effects on final products

Due to the characteristics of the molecular structure of siloxane, the dosage is very small so on the whole almost no effects on the mechanical property of the final products. generally speaking, except elongation and impact strength will increase slightly, with no effects on other mechanical properties. At a large dosage, it has a synergistic effect with flame retardant agents.

Due to its outstanding performance on high and low-temperature resistance, it will no side effects on the high and low-temperature resistance of the final products. while the flow of resin, processing, and surface properties will be improved obviously and the COF will be reduced.

Action mechanism

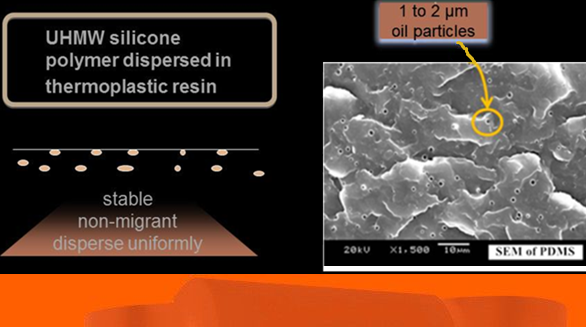

Silicone masterbatches are ultra-high molecular weight polysiloxane dispersed in different carrier resins which is a kind of function masterbatch. When ultra-high molecular weight silicone masterbatches are added into plastics for their nonpolar and with low surface energy, it has a trend to migrate to the plastic surface during the melting process; while, since it has a large molecular weight, it can’t move out completely. So we call it harmony and unity between migration and non-migration. due to this property, a dynamic lubrication layer formed between the plastic surface and the screw.

With processing keep going on, this lubrication layer is constantly being taken away and produced. So the flow of resin and processing are getting improved constantly and reducing electric current, equipment torque and improving the output. After the processing of twin-screw, silicone masterbatches will be evenly distributed in plastics and form a 1 to 2-micron oil particle under the microscope, those oil particles will offer the products a better appearance, nice hand feeling, lower COF, and greater abrasion and scratch resistance.

From the picture we can see that silicone will become small particles after being scattered in plastics, one thing we need to point out is that dispersibility is the key index for silicone masterbatches, the smaller of the particles, the more evenly distributed, the better result we will get.

Post time: May-26-2023