Outsole solutions for abrasion resistance

Outsole solutions for abrasion resistance,

abrasion resistance, Color RUBBER, EVA, PVC compounds, TPR, TPU, TR,

Description

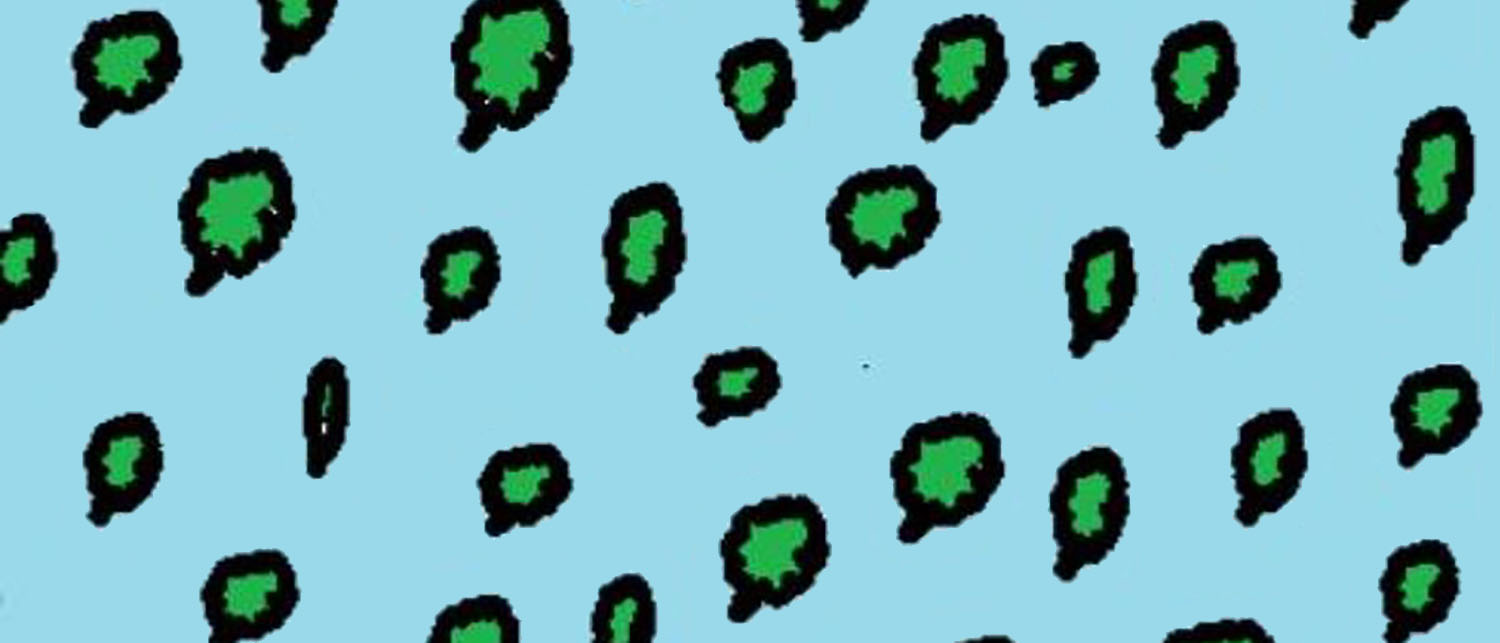

SILIKE Si-TPV is a patented dynamic vulcanizated thermoplastic Silicone-based elastomers which made by a special compatible technology , it helps silicone rubber dispersed in TPU evenly as a 2~3 micron droplets under microscope . This unique material provides a good combination of properties and benefits from thermoplastics and fully cross-linked silicone rubber. Suits for wearable device surface, Phone bumper ,Electronic devices accessories ( earbuds ,eg ), overmolding , artificial leather, Automotive, high-end TPE, TPU industries ….

Remark

The blue part is the flow phase TPU, which provides excellent mechanical properties.

The green part is silicone rubber particles provides silky skin-friendly touch, high and low-temperature resistance, weather resistance, stain resistance, etc.

The black part is a special compatible material, which improves the compatibility of TPU and silicone rubber, combines the excellent properties of the two, and overcomes the shortcomings of a single material.

3100 series

| Test item | 3100-55A | 3100-65A | 3100-75A | 3100-85A |

| Modulus of Elasticity ( Mpa ) | 1.79 | 2.91 | 5.64 | 7.31 |

| Elongation at break (%) | 571 | 757 | 395 | 398 |

| Tensile strength(Mpa) | 4.56 | 10.20 | 9.4 | 11.0 |

| Hardness ( Shore A ) | 53 | 63 | 78 | 83 |

| Density (g/cm3) | 1.19 | 1.17 | 1.18 | 1.18 |

| MI( 190℃,10KG) | 58 | 47 | 18 | 27 |

3300 series — Antibacterial

| Test item | 3300-65A | 3300-75A | 3300-85A |

| Modulus of Elasticity ( Mpa ) | 3.84 | 6.17 | 7.34 |

| Elongation at break (%) | 515 | 334 | 386 |

| Tensile strength(Mpa) | 9.19 | 8.20 | 10.82 |

| Hardness ( Shore A ) | 65 | 77 | 81 |

| Density (g/cm3) | 120 | 1.22 | 1.22 |

| MI( 190℃,10KG) | 37 | 19 | 29 |

Mark: The above data is only used as a typical product index, not as a technical index

Benefits

1. Provide the surface with Unique silky and skin-friendly touch, soft hand feel with good mechanical properties .

2. Not contain plasticizer and softening oil, no bleeding / sticky risk, no odors.

3. UV stable and chemical resistance with excellent bonding to TPU and similar polar substrates.

4. Reduce dust adsorption , oil resistance and less pollute .

5. Easy to demould, and easy to handle

6. Durable abrasion resistance & crush resistance

7. Excellent flexibility and kink resistance

How to use

1. Directly injection molding

2. Mix SILIKE Si-TPV® 3100-65A and TPU at a certain proportion , then extrusion or injection

3. It can be processed with reference to TPU processing conditions , recommend processing temperature is 160~180 ℃

Remark

1. The process conditions may vary with individual equipment and processes .

2. A desiccant dehumidifying drying is recommended for all drying

Typical application case study

The advantages of wristband which made by Si-TPV 3100-65A:

1. Silky, Friendly-skin touch, suits for kids as well

2. Excellent encapsultaion performance

3. Good dyeing performance

4. Good release performance and easy for processing

Package

25KG / bag , craft paper bag with a PE inner bag

Shelf life and storge

Transport as non-hazardous chemical. Store in a cool, well ventilated place.

Original characteristics remain intact for 12 months from the production date, if kept in recommend storage.Usually used in outsole and ladies’High heel’s heel ,refer to TPR,EVA,PVC and TPU. However, mostly are TPR and EVA, commonly used abrasion resistance test for shoes material, eg. DIN/NBS/China national standard.no matter which way you used, When adding SILIKE Anti-wear silicone masterbatch into EVA/TPR/TR/TPU/Color RUBBER/PVC compounds, the abrasion resistance will have a significant improvement.

FREE SILICONE ADDITIVES AND Si-TPV SAMPLES MORE THAN 100 GRADES

Sample type

$0

- 50+

grades Silicone Masterbatch

- 10+

grades Silicone Powder

- 10+

grades Anti-scratch Masterbatch

- 10+

grades Anti-abrasion Masterbatch

- 10+

grades Si-TPV

- 8+

grades Silicone Wax