Silicone Masterbatch LYSI Series

Silicone Masterbatch ( Siloxane Masterbatch ) LYSI series is a pelletized formulation with 20~65% ultra high molecular weight siloxane polymer dispersed in various resin carrier. It is widely used as an efficient processing additive in it’s compatible resin system to improve the processing properties and modify surface quality.

Compare to conventional lower molecular weight Silicone / Siloxane additives,like Silicone oil, silicone fluids or other type processing aids, SILIKE Silicone Masterbatch LYSI series are expected to give improved benefits, eg,. Less screw slippage , improved mold release, reduce die drool, a lower coefficient of friction, fewer paint and printing problems, and a broader range of performance capabilities.

| Product name | Appearance | Effective component | Active content | Carrier resin | Recommend Dosage(W/W) | Application scope |

| Silicone Masterbatch SC920 | White Pellet | -- | -- | -- | 0.5~5% | -- |

| Silicone Masterbatch LYSI-401 | White pellet | Siloxane polymer | 50% | LDPE | 0.5~5% | PE PP PA TPE |

| Silicone Masterbatch LYSI-402 | White pellet | Siloxane polymer | 50% | EVA | 0.5~5% | PE PP PA EVA |

| Silicone Masterbatch LYSI-403 | White pellet | Siloxane polymer | 50% | TPEE | 0.5~5% | PET PBT |

| Silicone Masterbatch LYSI-404 | White pellet | Siloxane polymer | 50% | HDPE | 0.5~5% | PE PP TPE |

| Silicone Masterbatch LYSI-405 | White pellet | Siloxane polymer | 50% | ABS | 0.5~5% | ABS AS |

| Silicone Masterbatch LYSI-406 | White pellet | Siloxane polymer | 50% | PP | 0.5~5% | PE PP TPE |

| Silicone Masterbatch LYSI-307 | White pellet | Siloxane polymer | 50% | PA6 | 0.5~5% | PA6 |

| Silicone Masterbatch LYSI-407 | White pellet | Siloxane polymer | 30% | PA6 | 0.5~5% | PA |

| Silicone Masterbatch LYSI-408 | White pellet | Siloxane polymer | 30% | PET | 0.5~5% | PET |

| Silicone Masterbatch LYSI-409 | White pellet | Siloxane polymer | 50% | TPU | 0.5~5% | TPU |

| Silicone Masterbatch LYSI-410 | White pellet | Siloxane polymer | 50% | HIPS | 0.5~5% | HIPS |

| Silicone Masterbatch LYSI-311 | White pellet | Siloxane polymer | 50% | POM | 0.5~5% | POM |

| Silicone Masterbatch LYSI-411 | White pellet | Siloxane polymer | 30% | POM | 0.5~5% | POM |

| Silicone Masterbatch LYSI-412 | White pellet | Siloxane polymer | 50% | LLDPE | 0.5~5% | PE, PP, PC |

| Silicone Masterbatch LYSI-413 | White pellet | Siloxane polymer | 25% | PC | 0.5~5% | PC, PC/ABS |

| Silicone Masterbatch LYSI-415 | White pellet | Siloxane polymer | 50% | SAN | 0.5~5% | PVC, PC, PC&ABS |

| Silicone Masterbatch LYSI-501 | White pellet | Siloxane polymer | -- | PE | 0.5~6% | PE PP PA TPE |

| Silicone Masterbatch LYSI-502C | White pellet | Siloxane polymer | -- | EVA | 0.2~5% | PE PP EVA |

| Silicone Masterbatch LYSI-506 | White pellet | Siloxane polymer | -- | PP | 0.5~7% | PE PP TPE |

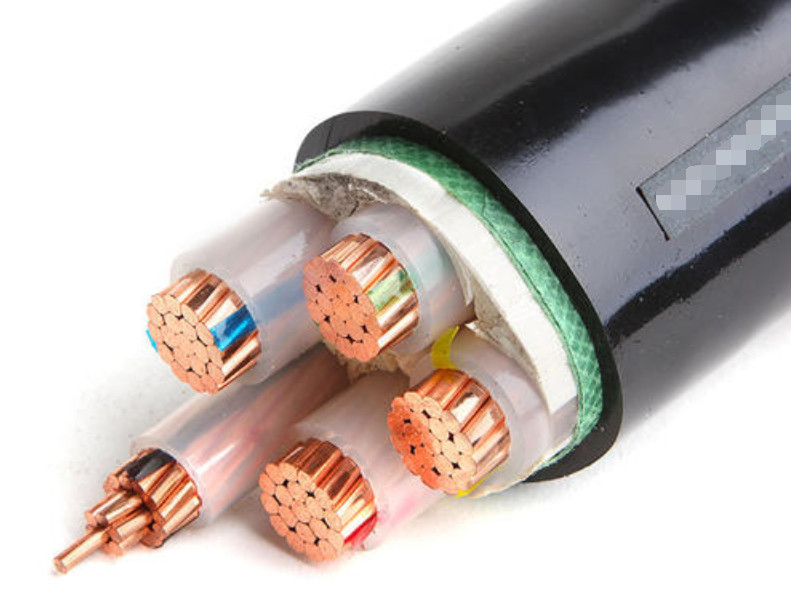

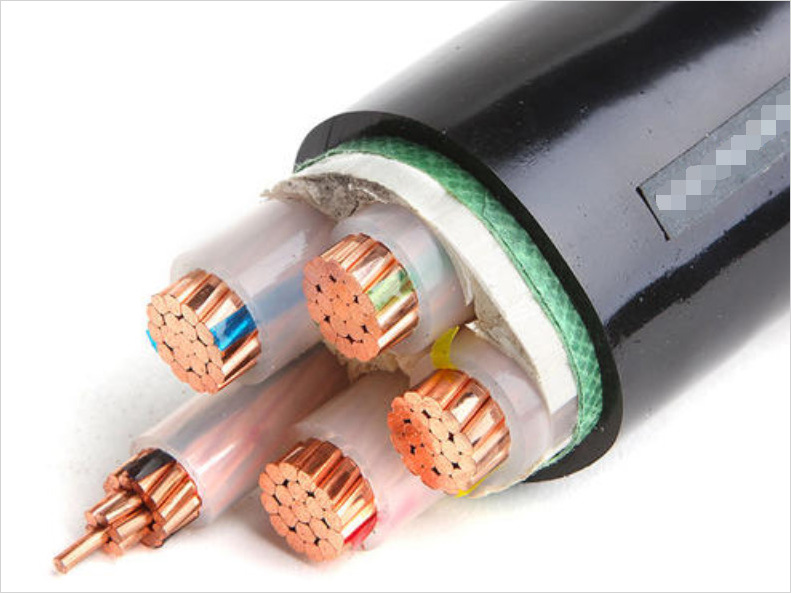

| Silicone Masterbatch LYPA-208C | White pellet | Siloxane polymer | 50% | LDPE | 0.2~5% | PE, XLPE |

Silicone Powder

Silicone powder ( Siloxane powder ) LYSI series is a powder formulation which contains 55~70% UHMW Siloxane polymer dispersed in Silica . Suitable for various applications like wire&cable compounds, engineering plastics,color/ filler masterbatches...

Compare to conventional lower molecular weight Silicone / Siloxane additives,like Silicone oil, silicone fluids or other type processing aids, SILIKE Silicone powder is expected to give improved benefits on processing proopertise and modify the surface quality of final products, eg,. Less screw slippage , improved mold release, reduce die drool, a lower coefficient of friction, fewer paint and printing problems, and a broader range of performance capabilities.What’s more, it has synergistic flame retardancy effects when combined with aluminum phosphinate and other flame retardants.

| Product name | Appearance | Effective component | Active content | Carrier resin | Recommend Dosage(W/W) | Application scope |

| Silicone Powder LYSI-100A | White powder | Siloxane polymer | 55% | -- | 0.2~5% | PE,PP,EVA,PC,PA,PVC,ABS.... |

| Silicone Powder LYSI-100 | White powder | Siloxane polymer | 70% | -- | 0.2~5% | PE,PP,PC,PA,PVC,ABS.... |

| Silicone Powder LYSI-300C | White powder | Siloxane polymer | 65% | -- | 0.2~5% | PE,PP,PC,PA,PVC,ABS.... |

| Silicone Powder S201 | White powder | Siloxane polymer | 60% | -- | 0.2~5% | PE,PP,PC,PA,PVC,ABS.... |

Anti-scratch Masterbatch

SILIKE Anti-scratch masterbatch has an enhanced compatibility with the Polypropylene (CO-PP/HO-PP ) matrix -- Resulting in lower phase segregation of the final surface, which means it stays on the surface of the final plastics without any migration or exudation , reducing fogging , VOCS or Odors . Helps improve long-lasting anti-scratch properties of automotive interiors , by offering improvements in many aspects like Quality, Aging , Hand feel, Reduced dust buildup... etc. Suitable for variety of Automotive interior surface , such as : Door panels, Dashboards, Center Consoles, instrument panels...

| Product name | Appearance | Effective component | Active content | Carrier resin | Recommend Dosage(W/W) | Application scope |

| Anti-Scratch Masterbatch LYSI-413 |

White pellet | Siloxane polymer | 25% | PC | 2~5% | PC, PC/ABS |

| Anti-scratch Masterbatch LYSI-306H |

White pellet | Siloxane polymer | 50% | PP | 0.5~5% | PP,TPE,TPV... |

| Anti-scratch Masterbatch LYSI-301 |

White pellet | Siloxane polymer | 50% | PE | 0.5~5% | PE,TPE,TPV... |

| Anti-scratch Masterbatch LYSI-306 | White pellet | Siloxane polymer | 50% | PP | 0.5~5% | PP,TPE,TPV... |

| Anti-scratch Masterbatch LYSI-306C |

White pellet | Siloxane polymer | 50% | PP | 0.5~5% | PP,TPE,TPV... |

| Anti-scratch Masterbatch LYSI-405 |

White pellet | Siloxane polymer | 50% | ABS | 0.5~5% | ABS,PC/ABS, AS... |

Anti-abrasion Masterbatch

SILIKE Anti-abrasion masterbatches NM series is particularly developed for the footwear industry. Currently, we have 4 grades that are respectively suitable for EVA/PVC, TPR/TR, RUBBER and TPU shoe’s sole. A small addition of them can effectively improve the final item's abrasion resistance and decrease the abrasion value in the thermoplastics. Effective for DIN, ASTM, NBS, AKRON, SATRA, GB abrasion tests.

| Product name | Appearance | Effective component | Active content | Carrier resin | Recommend Dosage(W/W) | Application scope |

| Anti-abrasion Masterbatch LYSI-10 |

White pellet | Siloxane polymer | 50% | HIPS | 0.5~8% | TPR,TR... |

| Anti-abrasion Masterbatch NM-1Y |

White pellet | Siloxane polymer | 50% | SBS | 0.5~8% | TPR,TR... |

| Anti-abrasion Masterbatch NM-2T |

White pellet | Siloxane polymer | 50% | EVA | 0.5~8% | PVC, EVA |

| Anti-abrasion Masterbatch NM-3C |

White pellet | Siloxane polymer | 50% | RUBBER | 0.5~3% | Rubber |

| Anti-abrasion Masterbatch NM-6 |

White pellet | Siloxane polymer | 50% | TPU | 0.2~2% | TPU |

Anti-squeaking Masterbatch

Silike's anti-squeaking masterbatch is a special polysiloxane that provides excellent permanent anti-squeaking performance for PC / ABS parts at a lower cost. Since the anti-squeaking particles are incorporated during the mixing or injection molding process, there is no need for post-processing steps that slow down the production speed. It is important that SILIPLAS 2070 masterbatch maintain the mechanical properties of PC/ABS alloy-including its typical impact resistance. By expanding design freedom, this novel technology can benefit automotive OEMs and all walks of life. In the past, due to post-processing, complex part design became difficult or impossible to achieve complete post-processing coverage. In contrast, silicone additives do not need to modify the design to optimize their anti-squeaking performance. Silike's SILIPLAS 2070 is the first product in the new series of anti-noise silicone additives, which may be suitable for automobiles, transportation, consumer, construction and home appliances.

| Product name | Appearance | Effective component | Active content | Carrier resin | Recommend Dosage(W/W) | Application scope |

| Anti-squeak MasterbatchSILIPLAS 2073 | white pellet | Siloxane polymer | -- | -- | 3~8% | PC/ABS |

| Anti-squeak Masterbatch SILIPLAS 2070 |

White pellet | Siloxane polymer | -- | -- | 0.5~5% | ABS,PC/ABS |

Additive Masterbatch For WPC

SILIKE WPL 20 is a solid pellet contain UHMW Silicone copolymer dispersed in HDPE , it is particularly designed for Wood-plastic composites. A small dosage of it can significantly improve the processing properties and surface quality, including reducing the COF , lower extruder torque, higher extrusion-line speed, durable scratch & abrasion resistance and excellent surface finish with a good hand feel. Suitable for HDPE, PP, PVC .. wood plastic composites.

| Product name | Appearance | Effective component | Active content | Carrier resin | Recommend Dosage(W/W) | Application scope |

| WPC Lubricant SILIMER 5407B | Yellow or yellow-off powder | Siloxane polymer | -- | -- | 2%~3.5% | Wood plastics |

| Additive Masterbatch SILIMER 5400 | White or off-white pellet | Siloxane polymer | -- | -- | 1~2.5% | Wood plastics |

| Additive Masterbatch SILIMER 5322 | White or off-white pellet | Siloxane polymer | -- | -- | 1~5% | Wood plastics |

| Additive Masterbatch SILIMER 5320 |

white-off white pellet | Siloxane polymer | -- | -- | 0.5~5% | Wood plastics |

| Additive Masterbatch WPL20 |

White pellet | Siloxane polymer | -- | HDPE | 0.5~5% | Wood plastics |

Super Slip Masterbatch

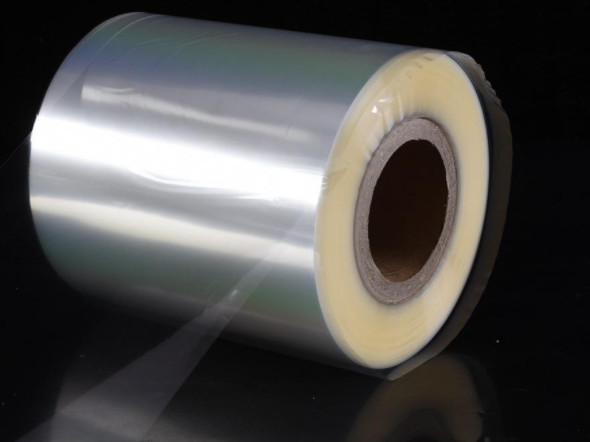

SILIKE Super-slip masterbatch has several grades with resin carrier like PE, PP, EVA, TPU..etc , contains 10%~50% UHMW Polydimethylsiloxane. A small addition of it can significantly lower the COF, improve the surface smoothness without any bleeding. Suitable for BOPP, CPP, BOPET, EVA, TPU film....

| Product name | Appearance | Effective component | Active content | Carrier resin | Recommend Dosage(W/W) | Application scope |

| Matt Effect Masterbatch 3135 | White Matt pellet | TPU | 5~10% | TPU | ||

| Anti-blocking Masterbatch FA111E6 | White or off-white pellet | PE | 2~5% | PE | ||

| Super Slip Masterbatch SF500E | White or off-white pellet | PE | 0.5~5% | PE | ||

| Super Slip Masterbatch SF240 | White or off-white pellet | PP | 2~12% | BOPP/CPP | ||

| Super Slip Masterbatch SF200 | White or off-white pellet | PP | 2~12% | BOPP/CPP | ||

| Super Slip Masterbatch SF105H | White or off-white pellet | PP | 0.5~5% | BOPP/CPP | ||

| Matt Effect Masterbatch 3235 | White Matt pellet | TPU | 5~10% | TPU | ||

| Super Slip Masterbatch SILIMER2514E | white pellet | EVA | 4~8% | EVA | ||

| Super Slip Masterbatch SF205 | white pellet | PP | 2~10% | BOPP/CPP | ||

| Super Slip Masterbatch SILIMER5065HB | White or off-white pellet | Siloxane polymer | -- | PP | 0.5~6% | PP |

| Super Slip Masterbatch SILIMER5064MB2 | white or light yellow pellet | Siloxane polymer | -- | PE | 0.5~6% | PE |

| Super Slip Masterbatch SILIMER5064MB1 | white or light yellow pellet | Siloxane polymer | -- | PE | 0.5~6% | PE |

| Super Slip Masterbatch SILIMER5065 | white or light yellow pellet | Siloxane polymer | -- | PP | 0.5~6% | PP/PE |

| Super Slip Masterbatch SILIMER5064A | white or light yellow pellet | Siloxane polymer | -- | PE | 0.5~6% | PP/PE |

| Super Slip Masterbatch SILIMER5064 | white or light yellow pellet | Siloxane polymer | -- | PE | 0.5~6% | PP/PE |

| Super Slip Masterbatch SILIMER5063A | white or light yellow pellet | Siloxane polymer | -- | PP | 0.5~6% | PP |

| Super Slip Masterbatch SILIMER5063 | white or light yellow pellet | Siloxane polymer | -- | PP | 0.5~6% | PP |

| Super Slip Masterbatch SILIMER5062 | white or light yellow pellet | Siloxane polymer | -- | LDPE | 0.5~6% | PE |

| Anti-blocking Masterbatch FA112R | White or off-white pellet | Siloxane polymer | -- | Co-polymer PP | 2~8% | BOPP/CPP |

| Super Slip Masterbatch SF110 | White Pellet | Siloxane polymer | -- | PP | 2~10% | BOPP/CPP |

| Super Slip Masterbatch SF105D | White Pellet | Siloxane polymer | -- | PP | 2~10% | BOPP/CPP |

| Super Slip Masterbatch SF105B | White Pellet | Siloxane polymer | -- | PP | 2~10% | BOPP/CPP |

| Super Slip Masterbatch SF105A | White or off-white pellet | Siloxane polymer | -- | PP | 2~10% | BOPP/CPP |

| Super Slip Masterbatch SF105 | White Pellet | Siloxane polymer | -- | PP | 5~10% | BOPP/CPP |

| Super Slip Masterbatch SILIMER 5064C | white pellet | Synthetic silica | -- | PE | 0.5~6% | PE |

| Super Slip Masterbatch SF109 | White pellet | Siloxane polymer | -- | TPU | 6~10% | TPU |

| Super Slip Masterbatch SF102 | White pellet | Siloxane polymer | -- | EVA | 6~10% | EVA |