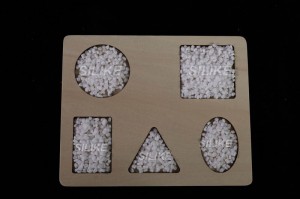

Silicone hyperdispersants SILIMER 6150 for inorganics fillers, pigments, flame retardants to improve the dispersion properties

Description

Product Specifications

|

Grade |

SILIMER 6150 |

|

Appearance |

white or white-off powder |

|

Active Concentration |

50% |

|

Volatile |

<4% |

|

Bulk density(g/ml) |

0.2~0.3 |

|

Recommend dosage |

0.5~6% |

Applications

Advantages

1) Higher filler content, better dispersion;

2) Improve the gloss and surface smoothness of products ( lower COF) ;

3) Improved melt flow rates and dispersion of fillers, better mold release and processing efficiency;

4) Improved color strength, no negative affect on mechanical properties; 5) Improve flame retardant dispersion thus providing a synergistic effect.

How to use

Addition levels between 0.5~ 6% are suggested depends on the required properties. It can be used in classical melt blending process like Single /Twin screw extrusion, injection molding. It can be used for pre-treatment of fillers

Transportation & Storage

This product could be transported as non-hazardous chemical. It is recommended to be stored in a dry and cool area with a storage temperature below 40 ° C to avoid agglomeration. The package must be well sealed after each use to prevent the product from being affected by moisture.

Package & Shelf life

25KG/BAG. Original characteristics remain intact for 24 months from the production date if kept in recommend storage.

FREE SILICONE ADDITIVES AND Si-TPV SAMPLES MORE THAN 100 GRADES

Sample type

$0

- 50+

grades Silicone Masterbatch

- 10+

grades Silicone Powder

- 10+

grades Anti-scratch Masterbatch

- 10+

grades Anti-abrasion Masterbatch

- 10+

grades Si-TPV

- 8+

grades Silicone Wax