SILIKE Anti-scratch masterbatch LYSI-306 provides scratch resistance solutions to auto interior PP material

Introduction

As the automotive industry continues to evolve, manufacturers are looking for ways to improve the quality of their vehicles. the most important aspect of vehicle quality is the interior, which needs to be durable, resistant to scratches, and low VOC…

PP has been widely used in automobiles interior for its characteristics of high-cost performance, low density, excellent heat resistance, chemical corrosion resistance, easy molding processing, and recycling.

However, PP is easily scratched by sharp objects, and its surface can be easily damaged by abrasion. Additionally, PP is prone to UV degradation, which can further reduce its scratch resistance.the scratch and mar performance of these products typically doesn’t fulfill all customer expectations.

And, The traditional anti-scratch agent contains a high amount of volatile organic compounds (VOCs). These VOCs can easily evaporate and be released into the air when applied to polypropylene (PP) surfaces. This can lead to an increase in the VOC content of the PP, which can be hazardous to human health.

How to improve scratch resistance while controlling the VOCs level of polypropylene material?

Solutions

SILIKE Anti-scratch masterbatch series product is pelletized formulation with ultra-high molecular weight siloxane polymer dispersed in polypropylene and other thermoplastic resins and has good compatibility with the plastic substrate. that provides superior scratch resistance for PP and TPO auto-body parts, and enhanced compatibility with the Polypropylene matrix — Resulting in lower phase segregation of the final surface, which means it stays on the surface of the final plastics without any migration or exudation, reducing fogging, VOCs (volatile organic compounds) which helps to improve air quality in the vehicle interior from the source. This makes it an ideal solution for those looking to reduce emissions from their vehicles. and is easy to incorporate as they consist of solid pellets.

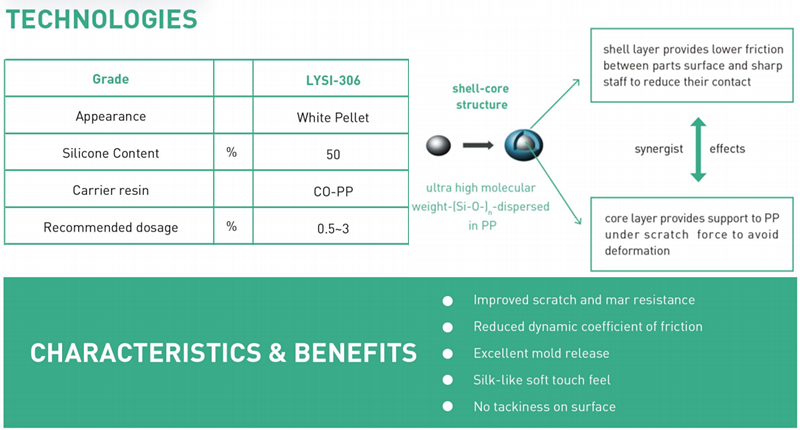

SILIKE Anti-scratch masterbatch LYSI-306 provide anti-scratch solutions to various PP/Talc interior application, with dosage from 0.5% to 3% of LYSI-306, the scratch resistance of finished parts meets the standard of VW PV3952, GM GMW14688, Ford, etc

Since LYSI-306 is a pelletized formulation with 50% ultra-high molecular weight siloxane polymer dispersed in Polypropylene (PP ). A small addition will impart long-lasting scratch resistance for plastic parts, as well as better surface quality like aging resistance, hand feel, reduce dust accumulation, etc.,

Techniques

Applications:

Widely used in all kinds of PP, TPO, TPE, TPV, PC, ABS, PC/ABS modified materials, automotive interiors, household appliance shells, and sheets, such as door panels, dashboards, center consoles, instrument panels, home appliance door panels, sealing strips.

For more information about Anti-scratch masterbatch additives, or For professional technical support, please contact us:

Mobile / Whatsapp : + 86-15108280799

Email: amy.wang@silike.cn

Or you can send us your inquiry by filling in the text on the right. Welcome, remember to leave us your phone number so we can contact you in time.

FREE SILICONE ADDITIVES AND Si-TPV SAMPLES MORE THAN 100 GRADES

Sample type

$0

- 50+

grades Silicone Masterbatch

- 10+

grades Silicone Powder

- 10+

grades Anti-scratch Masterbatch

- 10+

grades Anti-abrasion Masterbatch

- 10+

grades Si-TPV

- 8+

grades Silicone Wax