SILIKE SI-TPV

Description

SILIKE Si-TPV is a dynamic vulcanizated thermoplastic Silicone-based elastomers which made by a special compatible technology , it helps silicone rubber dispersed in TPU evenly as a 2~3 micron droplets under microscope . This unique material provides a good combination of properties and benefits from thermoplastics and fully cross-linked silicone rubber. Suits for wearable device surface, Phone bumper ,Electronic devices accessories ( earbuds ,eg ), overmolding , artificial leather, Automotive, high-end TPE, TPU industries ....

Remark

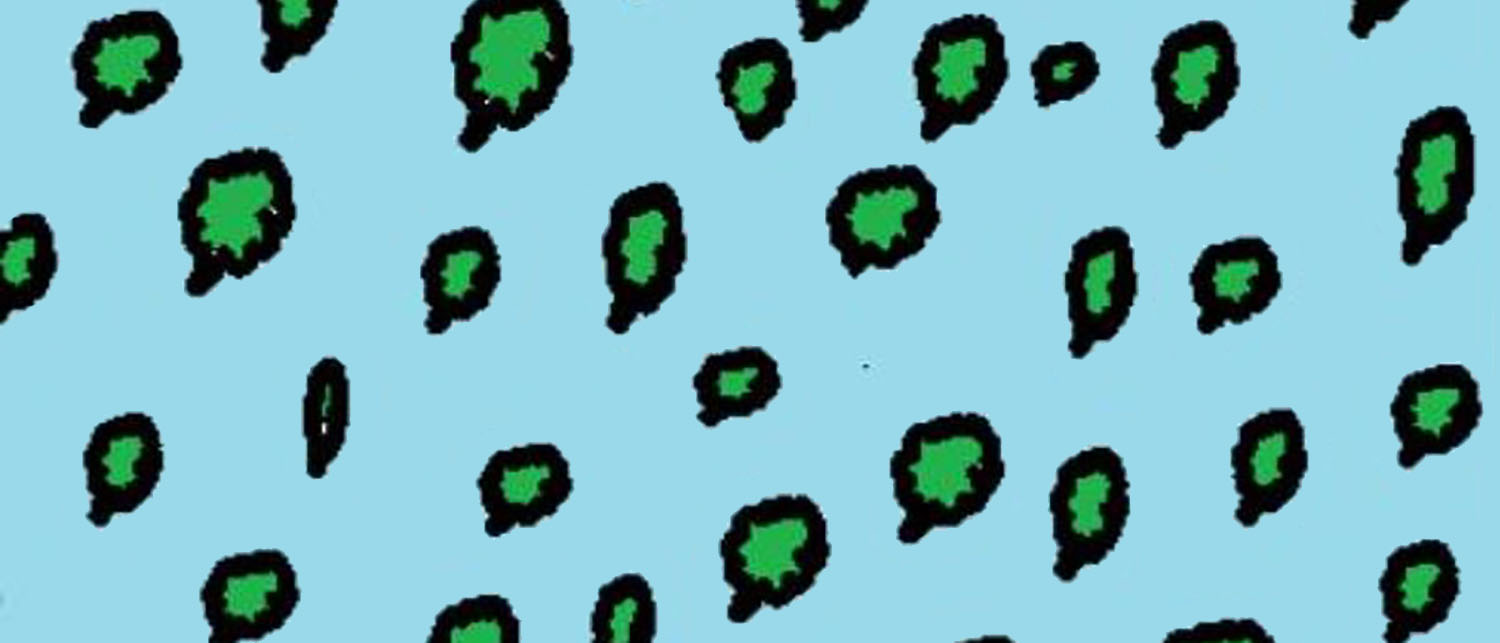

The blue part is the flow phase TPU, which provides excellent mechanical properties.

The green part is silicone rubber particles provides silky skin-friendly touch, high and low-temperature resistance, weather resistance, stain resistance, etc.

The black part is a special compatible material, which improves the compatibility of TPU and silicone rubber, combines the excellent properties of the two, and overcomes the shortcomings of a single material.

3100 series

| Test item | 3100-55A | 3100-65A | 3100-75A | 3100-85A |

| Modulus of Elasticity ( Mpa ) | 1.79 | 2.91 | 5.64 | 7.31 |

| Elongation at break (%) | 571 | 757 | 395 | 398 |

| Tensile strength(Mpa) | 4.56 | 10.20 | 9.4 | 11.0 |

| Hardness ( Shore A ) | 53 | 63 | 78 | 83 |

| Density (g/cm3) | 1.19 | 1.17 | 1.18 | 1.18 |

| MI( 190℃,10KG) | 58 | 47 | 18 | 27 |

3300 series -- Antibacterial

| Test item | 3300-65A | 3300-75A | 3300-85A |

| Modulus of Elasticity ( Mpa ) | 3.84 | 6.17 | 7.34 |

| Elongation at break (%) | 515 | 334 | 386 |

| Tensile strength(Mpa) | 9.19 | 8.20 | 10.82 |

| Hardness ( Shore A ) | 65 | 77 | 81 |

| Density (g/cm3) | 120 | 1.22 | 1.22 |

| MI( 190℃,10KG) | 37 | 19 | 29 |

Mark: The above data is only used as a typical product index, not as a technical index

Benefits

1. Provide the surface with Unique silky and skin-friendly touch, soft hand feel with good mechanical properties .

2. Not contain plasticizer and softening oil, no bleeding / sticky risk, no odors.

3. UV stable and chemical resistance with excellent bonding to TPU and similar polar substrates.

4. Reduce dust adsorption , oil resistance and less pollute .

5. Easy to demould, and easy to handle

6. Durable abrasion resistance & crush resistance

7. Excellent flexibility and kink resistance

How to use

1. Directly injection molding

2. Mix SILIKE Si-TPV® 3100-65A and TPU at a certain proportion , then extrusion or injection

3. It can be processed with reference to TPU processing conditions , recommend processing temperature is 160~180 ℃

Remark

1. The process conditions may vary with individual equipment and processes .

2. A desiccant dehumidifying drying is recommended for all drying

Typical application case study

The advantages of wristband which made by Si-TPV 3100-65A:

1. Silky, Friendly-skin touch, suits for kids as well

2. Excellent encapsultaion performance

3. Good dyeing performance

4. Good release performance and easy for processing

Package

25KG / bag , craft paper bag with a PE inner bag

Shelf life and storge

Transport as non-hazardous chemical. Store in a cool, well ventilated place.

Original characteristics remain intact for 12 months from the production date, if kept in recommend storage.

FREE SILICONE ADDITIVES AND Si-TPV SAMPLES MORE THAN 100 GRADES

Sample type

$0

- 50+

grades Silicone Masterbatch

- 10+

grades Silicone Powder

- 10+

grades Anti-scratch Masterbatch

- 10+

grades Anti-abrasion Masterbatch

- 10+

grades Si-TPV

- 8+

grades Silicone Wax