Slip and anti-block masterbatch for EVA film SILIMER 2514E

Description

SILIMER 2514E is a slip and anti-block silicone masterbatch specially developed for EVA film products. Using specially modified silicone polymer copolysiloxane as the active ingredient, it overcomes the key shortcomings of general slip additives: including that the slip agent will continue to precipitate from the film surface, and the slip performance will change over time and temperature. Increase and decrease, smell, friction coefficient changes, etc. It is widely used in the production of EVA blown film, cast film and extrusion coating, etc.

Properties

|

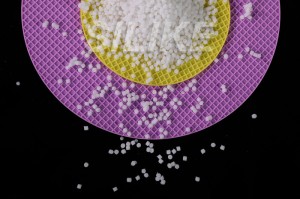

Appearance |

white pellet |

|

Carrier |

EVA |

|

Volatile content(%) |

≤0.5 |

|

Melt index (℃) (190℃,2.16kg)(g/10min) |

15~20 |

|

Apparent density(kg/m³) |

600~700 |

Benefits

1.When used in EVA films, it can improve the opening smoothness of the film, avoid adhesion problems during the preparation process of the film, and significantly reduce the dynamic and static friction coefficients on the film surface, with little impact on transparency.

2.It uses copolymerized polysiloxane as the slippery component, has a special structure, has good compatibility with the matrix resin, and has no precipitation, which can effectively solve the migration problems.

3.The slip agent component contains silicone segments, and the product has good processing lubricity, which can improve processing efficiency.

How to use

SILIMER 2514E masterbatch is used for film extrusion, blow molding, casting, calendering and other molding methods. The processing performance is the same as that of the base material. There is no need to change the process conditions. The addition amount is generally 4 to 8%, which can be determined according to the product characteristics of the raw materials. Make appropriate adjustments to the thickness of the production film. When using, add the masterbatch directly to the base material particles, mix evenly and then add it to the extruder.

Packaging

The standard packaging is a paper-plastic composite bag with a net weight of 25 kg/bag. Stored in a cool and ventilated place, the shelf life is 12 months.

FREE SILICONE ADDITIVES AND Si-TPV SAMPLES MORE THAN 100 GRADES

Sample type

$0

- 50+

grades Silicone Masterbatch

- 10+

grades Silicone Powder

- 10+

grades Anti-scratch Masterbatch

- 10+

grades Anti-abrasion Masterbatch

- 10+

grades Si-TPV

- 8+

grades Silicone Wax