Slip Silicone Masterbatch SF105 For BOPP/CPP Blown Films

Description

SF105 is an innovated smooth masterbatch specially developed and produced for BOPP/CPP film products. With specially modified poly dimethyl siloxane as the active ingredient, this product overcomes the key defects of general slip additives, including the slip agent continuous precipitation from the surface of the film, the smooth performance will decrease with time goes by and temperature increasing, odor, etc.

SF105 slip masterbatch is suitable for BOPP/CPP film blowing molding, casting molding, processing performance is the same as the base material, no need to change.

Process conditions: widely used in the production of BOPP/CPP blowing film, casting film and extrusion coating and so on.

Product Specifications

|

Grade |

SF105 |

|

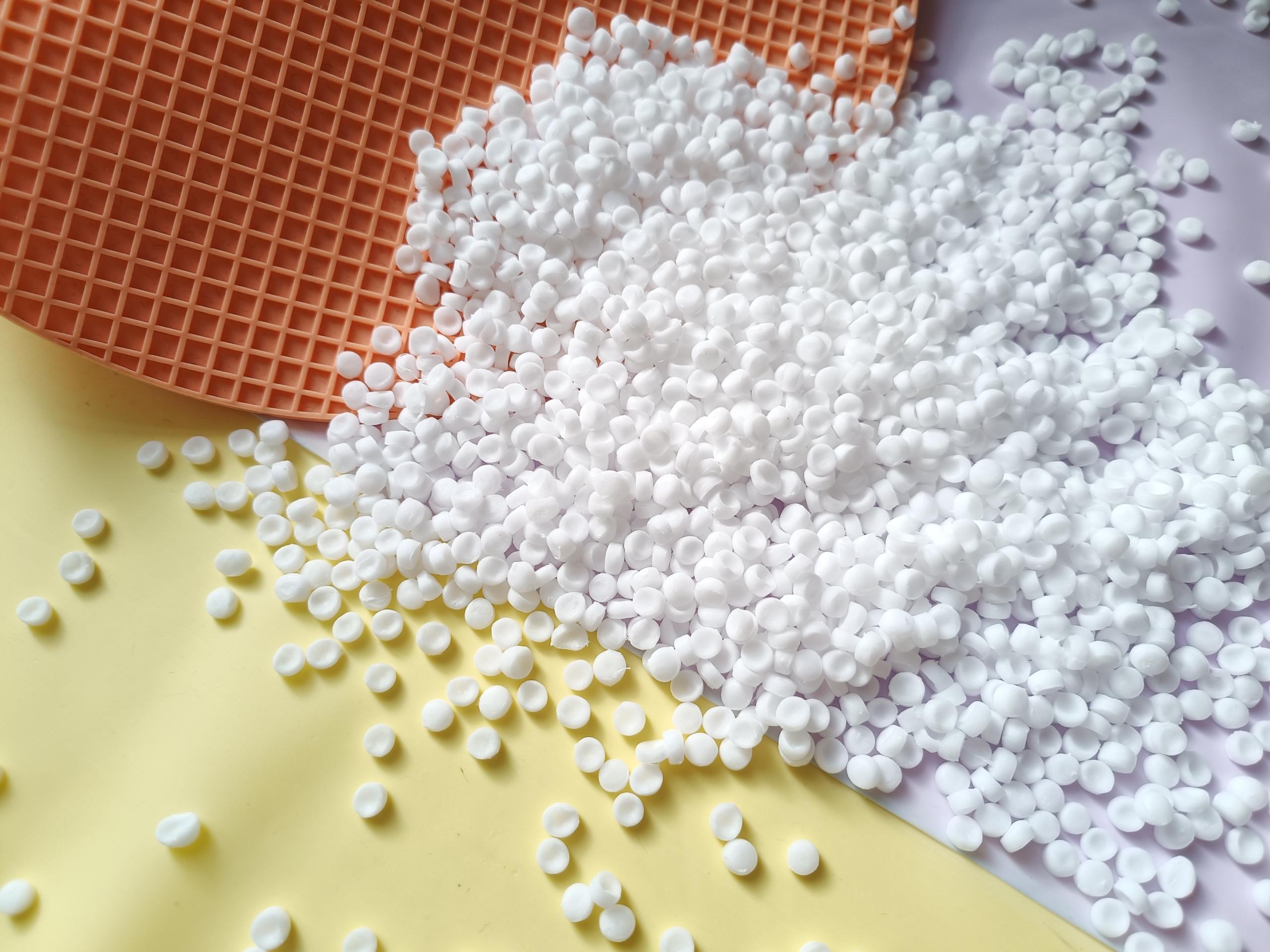

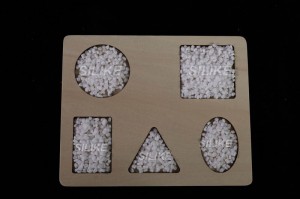

Appearance |

white pellet |

|

MI(230℃,2.16kg)(g/10min) |

5~10 |

|

Surface density(Kg/cm3) |

500~600 |

|

Carrier |

PP |

|

Volatile content(%) |

≤0.2 |

Benefits

1. SF105 is used for high speed cigarette film with good hot and smooth performance on metal.

2. When SF105 film is added, the friction coefficient has little effect with temperature. High temperature hot smooth effect is good.

3. SF105 can provide low friction coefficient. There will be no precipitation in the process of processing, will not produce white frost, prolong the cleaning cycle of equipment.

4. The maximum addition amount of SF105 in the film is 10% (generally 5~10%), and any higher addition amount will affect the film transparency. The larger the amount, the thicker the film, the greater the effect of transparency.

5. SF105 can be used in combination with inorganic anti-blocking masterbatch to obtain a lower friction coefficient. The content of inorganic anti-blocking agent is suggested to be 600-1000ppm.

6. If needs antistatic performance, could add antistatic masterbatch.

Application advantages

Surface performance: no precipitation, reduce the film surface friction coefficient, improve the surface smoothness;

Processing performance: good processing lubricity, improve processing efficiency.

How to use

SF105 slip masterbatch is used for BOPP/CPP film blowing molding and casting molding and the processing performance is same as the base material, no need to change.

Dosage is generally 2~ 10%, and can make proper adjustments according to the product characteristics of raw materials and the thickness of the production films.

During production, add the SF105 slip masterbatch directly to the substrate materials, mixed evenly and then added into the extruder.

Package

25Kg / bag , craft paper bag

Storage

Transport as non-hazardous chemical. Store in a cool , well ventilated place .

Shelf life

Original characteristics remain intact for 24 months from the production date, if kept in recommend storage.

FREE SILICONE ADDITIVES AND Si-TPV SAMPLES MORE THAN 100 GRADES

Sample type

$0

- 50+

grades Silicone Masterbatch

- 10+

grades Silicone Powder

- 10+

grades Anti-scratch Masterbatch

- 10+

grades Anti-abrasion Masterbatch

- 10+

grades Si-TPV

- 8+

grades Silicone Wax