Anti-Abrasion Masterbatch for Shoe Soles — Solve Wear Problems Without Sacrificing Comfort

Enhance Durability, Comfort, and Processability with SILIKE Anti-Abrasion Solutions for Footwear Compounds

In footwear manufacturing, outsole durability is a decisive factor that directly impacts product quality, brand reputation, and customer satisfaction. When shoe soles experience excessive abrasion, rapid wear, powdering, or surface whitening, it can lead to:

♦ Shortened shoe lifespan

♦ Appearance degradation and uneven wear

♦ Increased customer complaints, returns, and warranty risks

Most shoe soles are made from materials such as EVA, TPR, TR, TPU, PVC, and rubber due to their flexibility, lightweight properties, and design freedom. However, under repeated friction, bending, and long-term use, these materials often exhibit insufficient abrasion resistance and unstable processing performance—especially in high-stress applications such as sports, outdoor, and work footwear.

Traditional approaches to improve abrasion resistance usually include inorganic fillers (carbon black, silica, mineral fillers), waxes, oils, low molecular weight lubricants, and higher-hardness resin systems. These methods may offer temporary improvement, but they often cause new problems, such as:

♦ Increased hardness and reduced comfort

♦ Loss of elasticity and grip performance

♦ Surface migration, blooming, or whitening

♦ Poor long-term abrasion stability

Footwear manufacturers now demand solutions that can improve abrasion resistance while maintaining comfort, flexibility, surface appearance, color stability, processing stability, and consistent quality.

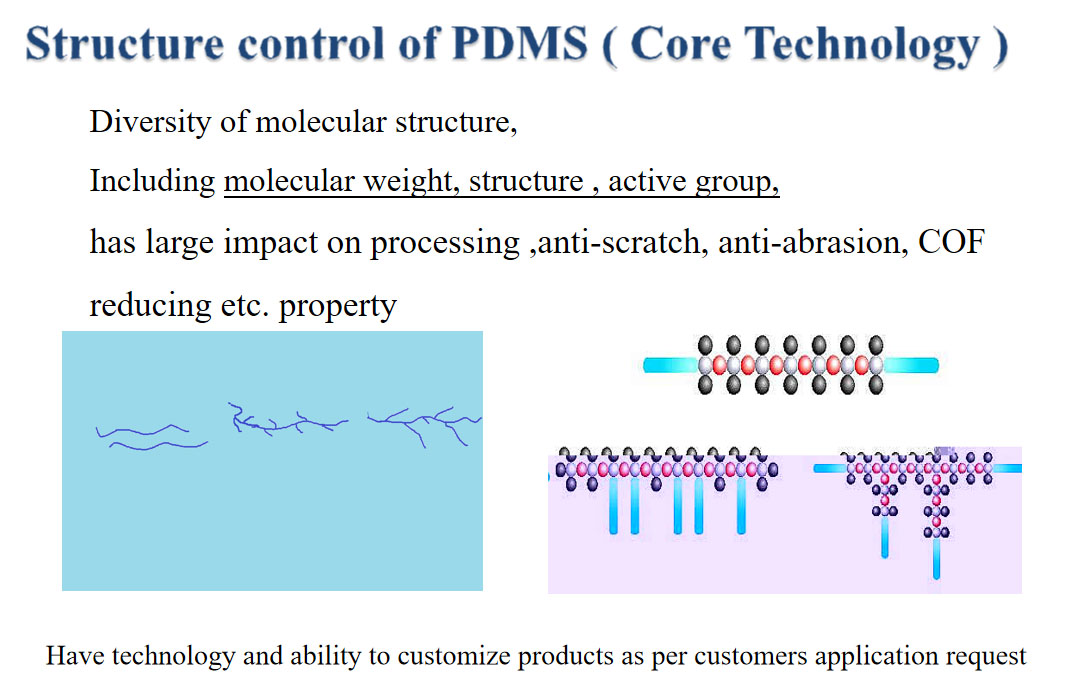

Since 2006, SILIKE has been dedicated to the footwear materials market, continuously advancing silicone modification technology to develop specialized anti-abrasion solutions for shoe soles.

SILIKE Anti-Abrasion Masterbatch focuses on enhancing wear resistance beyond the typical benefits of silicone additives. It is a proven, material-compatible solution that significantly improves abrasion resistance without compromising comfort, aesthetics, or processing efficiency.

The SILIKE Anti-Abrasion Masterbatch NM Series is a dedicated anti-wear additive designed for all kinds of plastics and rubber products.

This anti-abrasion additive series provides excellent processing performance and delivers uniform abrasion resistance throughout the footwear compound, both on the surface and within the material. At the same time, it enhances melt flowability and surface gloss, significantly extending the service life of shoe soles while maintaining an optimal balance of comfort, durability, and reliability.

SILIKE Anti-Abrasion Masterbatch is suitable for:

● EVA & Phylon foams

● TPR (Thermoplastic Rubber)

● TR compounds

● TPU outsoles

● PVC shoe soles

● NR / SBR / BR / NBR / EPDM rubber systems

● Modified footwear compounds

Wear-Resistant Agents for Shoe Soles Trusted by Footwear Compound Manufacturers

Based on extensive feedback from footwear compound manufacturers using PVC, EVA, SBS, SEBS, TR, TPR, and colored rubber compounds, SILIKE’s Anti-Abrasion Masterbatch Series has become one of the most widely adopted solutions for improving outsole wear resistance without sacrificing comfort or processability.

Recommended Solutions for Different Wear-resistant Sole Materials

NM-2T EVA Anti-Abrasion Masterbatch for Durable Footwear Soles

How to Improve EVA Shoe Sole Abrasion Resistance Without Affecting Comfort

NM-1Y Wear-Resistant Additive for TPR and TR Shoe Soles

Enhance Outsole Durability and Processing Stability

LYSI-10 TPR Wear-Resistant & Processing Aid

Improve Abrasion Resistance and Processing Efficiency in TPR Shoe Soles

NM-3C High-Performance Anti-Abrasion Additive for EPDM & Rubber Compounds

Long-Lasting Wear Resistance Without Mechanical Property Loss

NM-3 Anti-Abrasion Masterbatch for Rubber Shoe Soles

How to Extend Rubber Outsole Service Life Under High Abrasion Conditions

NM-6 TPU Anti-Abrasion & Slip Modifier for Durable Outsoles

Reduce Abrasion and Improve Slip Performance in TPU Shoe Soles

Why Choose SILIKE Silicone-Based Anti-Abrasion Masterbatch for Footwear Compounds?

1. Cost-Effective Wear Resistance at Low Dosage

Improve abrasion resistance with small addition levels (typically 0.5–1.5%), helping footwear compounders reduce formulation cost while maintaining comfort and performance.

2. Better Filler & Pigment Dispersion

Enhances dispersion of fillers and color pigments, resulting in more uniform surfaces, consistent mechanical properties, and fewer defects during molding or extrusion.

3. No Impact on Hardness or Elasticity

Maintains original hardness, rebound, and flexibility—critical for cushioning, grip, and wearer comfort.

4. Improved Color Strength & Surface Appearance

Boosts color intensity and surface gloss without blooming, whitening, or visual defects after abrasion.

5. Uniform Wear Resistance Throughout the Material

Provides consistent abrasion resistance from surface to inside, ensuring long-lasting durability for the whole outsole.

6. Improved Processing Efficiency

Enhances melt flow, mold filling, and release performance, reducing processing defects and improving production stability.

7. Extended Shoe Lifespan with Balanced Comfort

Significantly extends outsole service life while preserving flexibility, comfort, and structural integrity.

8. Environmentally Responsible & Stable Formulation

Silicone-based, non-migrating, low-odor additive that supports environmental compliance and sustainable footwear manufacturing.

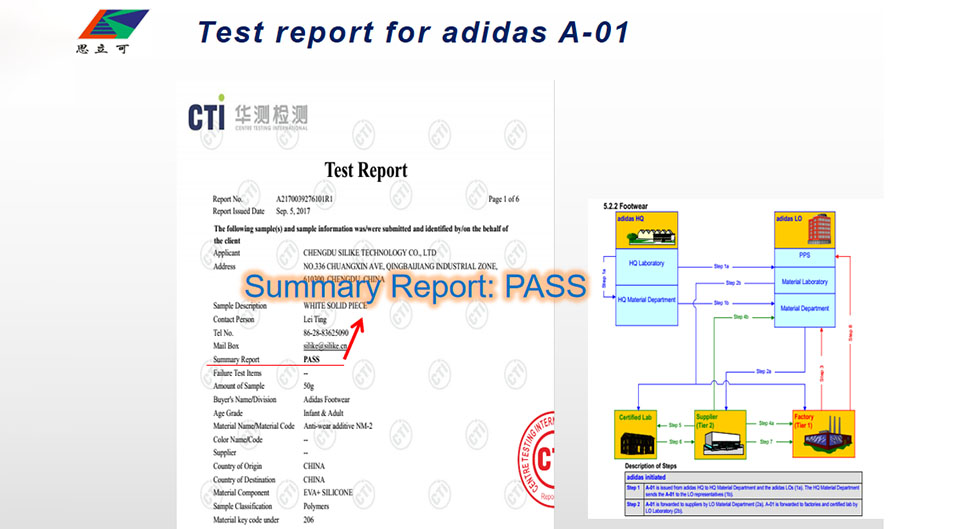

9. Proven Performance in Industry-Standard Tests

Effective in DIN, ASTM, NBS, AKRON, SATRA, and GB abrasion tests.

Case Studies & Product Applications

Footwear Anti-Abrasion Case Studies & Product Applications

Proven Anti-Abrasion Performance in Footwear Compounds Worldwide

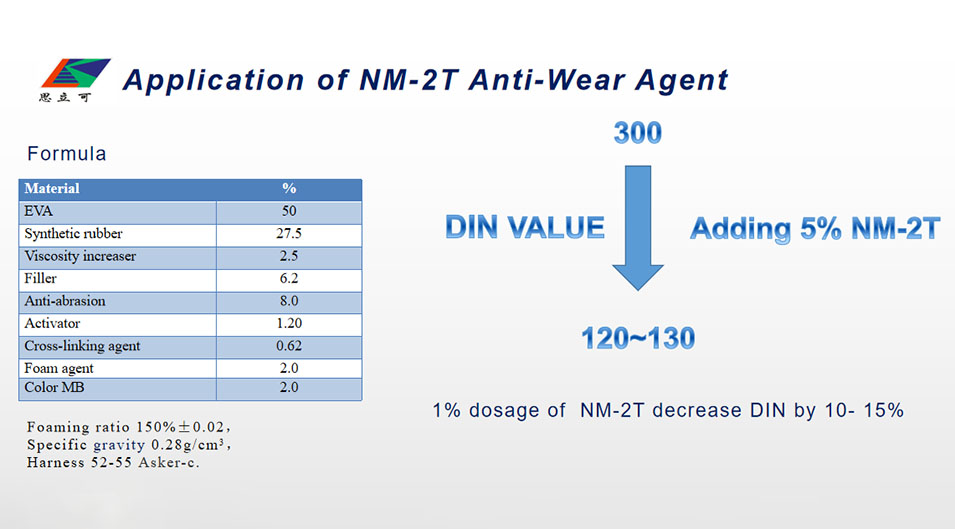

SILIKE NM-2T Anti-abrasion Agent — Enhance Abrasion Resistance of EVA Shoe Soles

Key Benefits:

• Improves abrasion resistance with reduced abrasion value in EVA shoe soles, reducing abrasion loss during daily wear and extending the lifespan of sports, casual, and outdoor footwear.

• 1% NM-2T reduces DIN abrasion by 10–15%.

• 5% NM-2T can lower DIN abrasion from ~300 to 120–130.

• Enhances processing performance and surface appearance: improves melt flow, mold filling, and surface gloss without compromising comfort.

• No affect on hardness, Slightly improve mechanical properties

Eco-friendly, non-migrating formulation compliant with global regulations.

• Effective in DIN, ASTM, NBS, AKRON, SATRA, and GB abrasion tests.

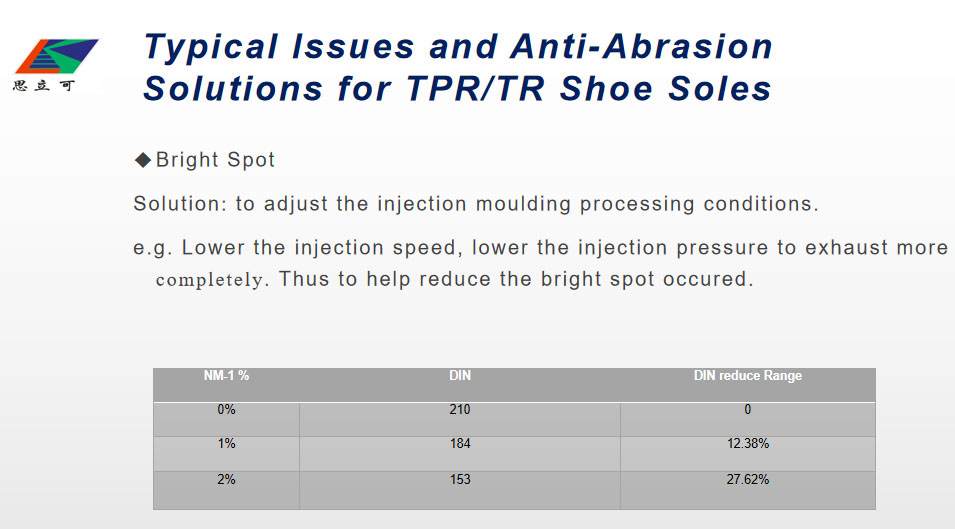

SILIKE NM-1Y Anti-Wear Agent — Enhance Abrasion Resistance of TPR Shoe Soles

Key Benefits:

• Reduces abrasion value in TPR/TR soles, enhancing wear resistance for sports, casual, and outdoor footwear.

• At 1% addition, NM-1 can reduce DIN abrasion by approximately 12.38%.

• Enhances processing stability and surface finish: improves melt flow, mold filling, and consistent gloss without affecting comfort.

• Maintains hardness and color stability with no adverse effect on compound properties.

• Eco-friendly formulation compliant with global footwear standards.

• Proven in DIN, ASTM, NBS, AKRON, SATRA, and GB abrasion tests.

• Low dosage, cost-effective, suitable for TPR, TR, SBS, and color compounds.

SILIKE LYSI-10 Anti-Abrasion Masterbatch for TR/TPR Outsoles — Improve Wear Resistance in Footwear

Key Benefits:

• Significantly improves abrasion resistance, lowering abrasion value in TR/TPR shoe soles.

• Enhances processing performance and surface appearance

• No influence on hardness or color, preserving original material properties.

• Eco-friendly formulation suitable for sustainable footwear manufacturing.

• Complies with DIN, ASTM, NBS, AKRON, SATRA, GB abrasion tests.

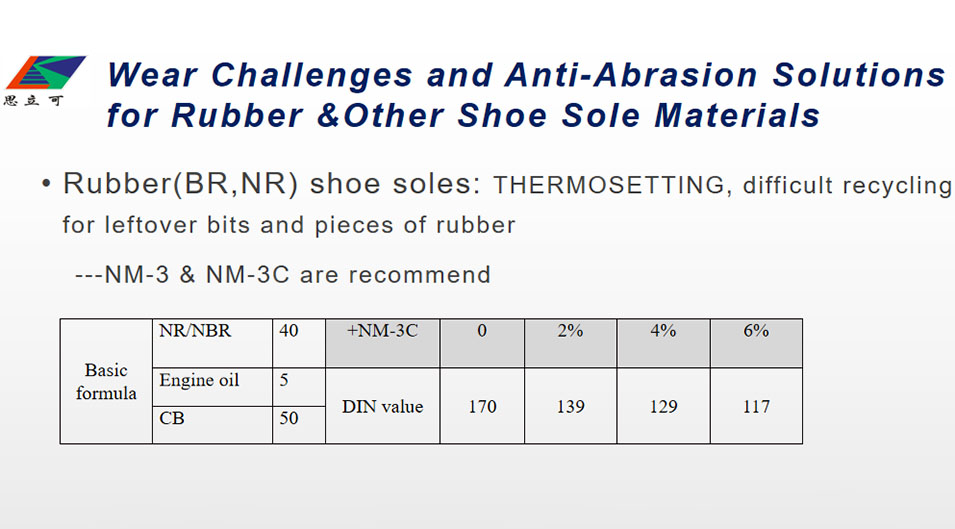

SILIKE NM-3C Anti-Wear Masterbatch for Rubber Outsoles — Improve Abrasion Resistance in Footwear

Key Benefits:

• Significantly reduces abrasion value, prolonging outsole lifespan

• At 2% addition, NM-3C can reduce the DIN abrasion value from approximately 170 to 139

• No effect on mechanical properties, hardness, or elasticity

• Enhances flowability, mold release, and surface finish

• Improves durability without compromising shoe comfort

• Eco-friendly and compatible with global footwear manufacturing standards

NM-3 Anti-Abrasion Masterbatch Solutions for Color Rubber Shoe Soles — Improve Wear Resistance & Extend Outsole Lifespan

Key Benefits:

• Improves abrasion resistance and reduces abrasion value in color rubber shoe soles.

• Enhances processing performance and surface appearance, delivering smooth finish and uniform gloss.

• Eco-friendly formulation, compliant with footwear safety requirements.

• No impact on hardness or color, preserving original material properties.

• Tested and compliant with DIN, ASTM, NBS, AKRON, SATRA, GB abrasion tests.

• Optimized for SBS and SBS-compatible resin systems in rubber outsoles.

TPU Shoe Sole Wear-Resistant Additive NM-6 — Anti-Abrasion Masterbatch for Footwear

Key Benefits:

• Improves abrasion resistance and reduces TPU outsole wear rate

• At 0.5% addition in TPU (hardness 85A), NM-6 can reduce DIN abrasion value from 100 to 60.

• Enhances melt flow, mold release, and final part appearance, improving processing efficiency.

• Eco-friendly additive suitable for sustainable footwear manufacturing.

• Complies with DIN, ASTM, NBS, AKRON, SATRA, GB abrasion tests.

Abrasion Test Results & Performance Evaluations

What Footwear Manufacturers Say About Our Anti-Abrasion Solutions

★★★★★

NM-2T – EVA Footwear Outsoles

"In our EVA footwear compounding, outsole wear and abrasion were major concerns. DIN abrasion values typically ranged from 200–300, which negatively impacted shoe lifespan and user comfort. Using SILIKE NM-2T, even a 1% dosage decreased DIN by 10–15%. With 5% NM-2T, we reduced DIN values from 300 to 120–130, significantly extending the service life of outsoles. The material maintained original hardness and comfort, while improving surface appearance and overall reliability."

— John Smith, EVA Footwear Compound Manufacturer

★★★★★

NM-3C Anti-Wear Agent for EPDM Rubber Soles — Enhance Abrasion Resistance & Extend Outsole Lifespan

We were looking for an anti-wear agent with excellent abrasion resistance for NBR compounds with 90 Shore A hardness. After adopting SILIKE NM-3C, specifically designed for rubber resins, our compounds demonstrated significantly improved abrasion resistance in NBR systems. The finished soles maintained their original hardness and color, while the surface durability and lifespan were greatly enhanced. NM-3C also improved processing performance, ensuring smoother molding and consistent quality without affecting our production conditions."

— Juan Pérez, Rubber Compounds R&D Manager, Footwear Manufacturer

★★★★★

NM-3 – Anti-Wear Agent for Color Rubber Outsoles

"In our EPDM outsole compounding, maintaining abrasion resistance while keeping high hardness Shore A has always been a challenge. Traditional fillers often degrade surface quality and reduce durability. After introducing SILIKE NM-3C, we observed a significant decrease in abrasion value, improved surface gloss, and no change in hardness. The finished outsoles now meet DIN, ASTM, and SATRA standards while maintaining excellent processability, reducing mold release issues, and extending product lifespan."

— Michael Tan, Rubber Footwear Compound Manufacturer

★★★★★

NM-1Y – Anti-Wear Agent for TPR/TR Outsoles

"In our TPR/TR sports shoe outsoles, achieving uniform abrasion resistance has been a recurring issue, especially under repeated bending and friction. Adding 2–3% NM-1Y resulted in a consistent reduction in DIN abrasion values, improved flowability, and smoother surface finish. The processing became more stable, and the shoes retained their comfort and design integrity throughout long-term wear."

— Li Wei, Sports Footwear Compound Developer

★★★★★

NM-6 – Anti-Wear Agent for TPU Outsoles

"TPU outsoles are prone to high COF and rapid abrasion, causing shortened product lifespan. After introducing NM-6 at just 1–2% dosage, we saw a substantial reduction in both COF and abrasion loss. The compound's mechanical properties and color remained unaffected, processing was smoother, and mold release improved. End users reported longer-lasting, comfortable, and visually consistent outsoles."

— Samantha Lee, TPU Footwear Manufacturer

★★★★★

LYSI-10 – Anti-Abrasion & Processing Aid for TPR Compounds

"TPR/TR compounds often suffer from poor abrasion resistance and inconsistent surface quality during high-speed extrusion. Incorporating 3% LYSI-10 into our PS-compatible TPR formulations enhanced abrasion resistance, lowered abrasion values, and improved surface gloss. Extrusion line stability improved, die drool was minimized, and we achieved consistent, high-quality shoe outsoles without affecting color or hardness."

— Rajesh Kumar, Footwear Compound Specialist

Improve Processing Efficiency, Extend Shoe Lifespan, and Balance Comfort with Reliability