Silicone Processing Additives and Surface Modifiers Solutions for Wire and Cable Applications

Improve Processability, Productivity, Performance, and Aesthetics in Wire and Cable Formulations

As wire and cable formulations continue to evolve toward higher safety standards, greater flexibility, and long-term durability, evolving trends and regulations, Manufacturers and processors of thermoplastic compounds are increasingly encountering recurring challenges during compounding and extrusion, including:

♦ High extrusion torque and unstable melt flow

♦ Melt fracture, die build-up, and rough surface appearance

♦ Sticky cable jackets with a high coefficient of friction (COF)

♦ Performance trade-offs between flame retardancy, flexibility, and mechanical durability

These challenges are particularly common in LSZH/HFFR cable compounds, high-speed wire and cable extrusion, as well as in XLPE, TPU, TPE, PVC, and rubber-based cable compounds.

SILIKE continuously advances efficient silicone modification technologies to deliver high-performance solutions that enhance processability, productivity, and surface quality in wire and cable applications.

For producers of wire and cable composite materials, SILIKE has been dedicated to the wire and cable industry since 2011. Our silicone additives are specifically formulated to address the most common formulation and processing challenges encountered in wire and cable compounding and extrusion.

These siloxane-based additives function as highly effective processing aids and lubricants, significantly improving:

♦ Cable and wire sheath/jacket processability

♦ Extrusion stability and overall productivity

♦ Surface smoothness, slip performance, and final appearance

Over the past decade, SILIKE’s silicone masterbatches have earned the trust of high-filler LSZH cable compound manufacturers, thanks to their proven performance in LLDPE / EVA / ATH (or MDH) highly filled LSZH polyolefin cable compounds, including: Improved dispersion of flame-retardant fillers (ATH / MDH), reduced thermal decomposition of flame retardants during processing, lower extrusion torque, improved melt flow, and increased line speed, particularly for small-diameter automotive wires and cables.

In addition, the Silike wire and cable compounding special thermoplastic additive series High-performance silicone and siloxane additives products are specially developed for all kinds of wire and cable products to improve the processing flow ability, increase the extrusion-line speed, enhance the filler dispersion performance, reduce extrusion die drool, improve abrasion and scratch resistance, and enhance the synergistic flame-retardant performance, etc.

Silicon-based additives technology from SILIKE can benefit wire and cable compounders and manufacturers. It enhances productivity through a combination of faster throughput and fewer interruptions. It helps to design best-in-class wire and cable compounds to respond to these demanding industry performance requirements. It makes products safer and stronger for better end-use performance, often while simultaneously improving aesthetics and sustainability outcomes.

Whether you are developing a new wire or cable compound, replacing traditional lubricants or fluoropolymer-based additives, or solving extrusion bottlenecks in high-filler or high-speed applications, SILIKE Silicone Additive Solutions help you achieve better performance across the entire value chain — from compounding and extrusion to final wire and cable performance.

SILIKE silicone-based plastics additives solutions are suitable for a wide range of wire and cable applications, including:

● Halogen-Free Flame Retardant (HFFR) Wire and Cable Compounds

● Low Smoke Zero Halogen (LSZH) Cable Compounds

● Silane Crosslinkable Polyolefin Compounds (Si-XLPE) for Wire and Cable

● Crosslinkable Polyolefin Cable Compounds

● Low-Smoke PVC Cable Compounds

● Low Coefficient of Friction (Low COF) Cable Compounds

● TPU Compounds for Wire and Cable Applications

● TPE (Thermoplastic Elastomer) Cable Compounds

● Rubber-Based Cable Compounds

● High-Speed Extrusion HFFR Cable Compounds

● EV Charging Cable Compounds

● ...

Wire and Cable Compounds Manufacturers' Favorite Processing Aids and Surface Modifiers

Based on client feedback, the most popular SILIKE Series silicone masterbatches, silicone powder, plastic processing lubricant, and multifunction additive products include:

LYSI-401 Silicone Masterbatch for Highly Filled Polyolefin-Based HFFR Compounds |To Improve ATH/MDH Dispersion, Solve Extrusion Processing Issues, and Enhance Cable Surface Performance

LYSI-502C Ultra-High Molecular Weight Silicone Additive for Highly Filled LSZH Cable Compounds | Reduce torque and die drool, Improve Lubrication, and faster line speed

LYPA-208C Silicone Masterbatch for Silane-XLPE Cable Compounds | Prevent Premature Crosslinking and Improve Surface Quality

LYSI-409 Silicone Masterbatch for Matte TPU Cable Compounds | Low COF, Enhanced Abrasion Resistance, and Dry Silky Surface Feel

LYSI-406 Silicone Masterbatch for TPE Wire and Cable Compounds | Increase Extrusion Line Speed While Maintaining Smooth, Wear-Resistant Surfaces

LYSI-100A Silicone Powder for Low-Smoke PVC Wire and Cable Compounds | Reduce COF and Improve Scratch Resistance for Cable Jackets

LYSI-300P Resin-Free Silicone Additive for LSZH and HFFR Cable Compounds | Pellet S Alternative to Reduce Die Pressure, Improve Process Stability, and Enhance Productivity

SC920 Co-Polysilicone Additive for High-Speed LSZH / HFFR Cable Extrusion | Increase Output Without Diameter Instability or Screw Slippage

SILIMER 6560 Multifunction silicone Additive for Rubber Cable Compounds | Improve Flow, Enhance Filler Dispersion, and Increase Extrusion Line Speed

Why Choose SILIKE Silicone-Based Additives for Wire & Cable Compounds in Processing Efficiency and Surface Aesthetics Modification?

1. Solve Processing Challenges

Achieve more uniform dispersion of flame-retardant fillers

Achieve more uniform dispersion of flame-retardant fillers

Significantly improve material flow

Significantly improve material flow

Optimize extrusion processes

Optimize extrusion processes

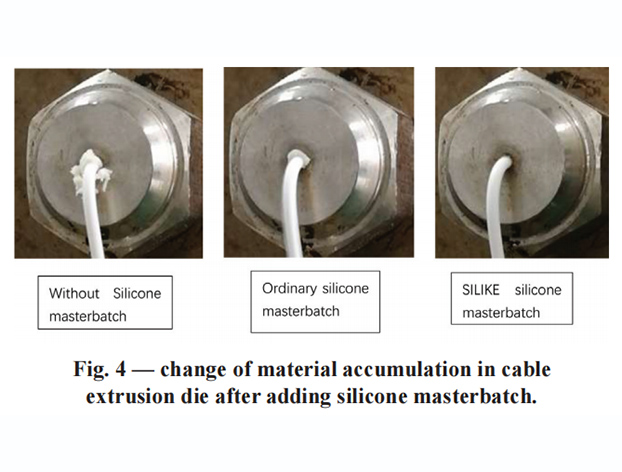

Reduce or eliminate die drool

Reduce or eliminate die drool

Lower energy consumption and decrease cycle time

Lower energy consumption and decrease cycle time

Enable faster line speeds

Enable faster line speeds

Maximize overall productivity

Maximize overall productivity

Restore mechanical properties, including impact strength and elongation at break

Restore mechanical properties, including impact strength and elongation at break

Enhance synergy with flame retardants

Enhance synergy with flame retardants

2. Surface Quality Improvement

Improve surface lubricity

Improve surface lubricity

Reduce the coefficient of friction

Reduce the coefficient of friction

Enhance abrasion resistance

Enhance abrasion resistance

Increase scratch resistance

Increase scratch resistance

Deliver superior surface feel and touch

Deliver superior surface feel and touch

SILIKE's silicone-based additives and modifiers improve the processing properties of plastic materials and the surface quality of finished components for wire and cable compounds.

SILIKE's silicone-based additives and modifiers improve the processing properties of plastic materials and the surface quality of finished components for wire and cable compounds.

Case Studies & Product Applications

Proven Performance in Wire & Cable Polymer Compounding Worldwide

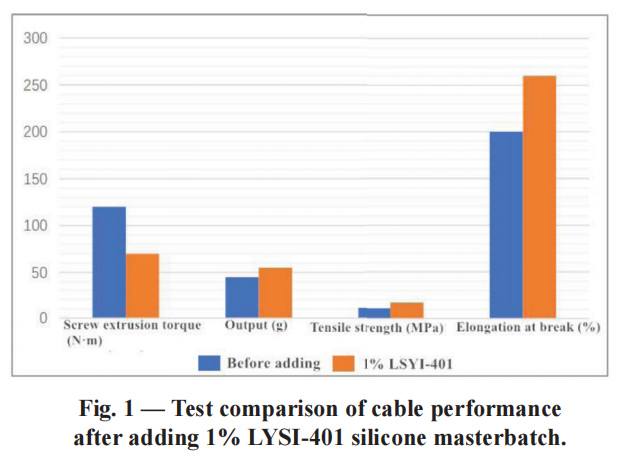

LYSI-401 Silicone Masterbatch for Highly Filled LSZH/HFFR Cable Compounds

Application: Low-Smoke Zero Halogen / Halogen-Free Flame Retardant Cable Compounds

Industry Pain Points:

• Poor melt flow due to high ATH/MDH loading

• Difficult extrusion, high torque & die pressure

• Compromised surface quality

• Mechanical property loss after aging

SILIKE Silicone Additive Benefits:

• Improves melt flow and dispersion of flame retardants

• Reduces die build-up and extrusion torque

• Enhances surface smoothness without blooming

• Maintains tensile strength & elongation

Result:

• Stable extrusion

• Optimized balance between flame retardancy and mechanical performance

• Better surface quality for LSZH/HFFR cables

LYSI-502C Ultra-High Molecular Weight Silicone Additive for Highly Filled LSZH/HFFR Cable Compounds

Industry Pain Points:

• High torque and die pressure during extrusion

• Poor surface finish

• Inconsistent additive dispersion

SILIKE Silicone Additive Benefits:

• Excellent internal and external lubrication

• Enhances dispersion of flame retardants and other functional additives

• Improves melt flow and extrusion stability

• Reduces die build-up and surface defects

Result:

• Smoother extrusion process

• Lower torque

• Consistent cable surface quality

LYPA-208C Silicone Masterbatch for Silane Crosslinking XLPE (Si-XLPE) Cable Compounds

Industry Pain Points:

• High friction during extrusion

• Uneven surface and sharkskin formation

• Narrow processing window

• Additives interfering with silane crosslinking

SILIKE Silicone Additive Benefits:

• Lowers melt friction and processing temperature

• Improves surface finish and extrusion stability

• No interference with silane grafting or crosslinking

• Enhances long-term cable performance

Result:

• Cleaner cable surface

• Reliable crosslinking behavior

• Smooth, stable extrusion

LYSI-409 Silicone Masterbatch for TPU Cable Compounds

Application: EV Charging, Data, and Flexible Cables

Industry Pain Points:

• Sticky surface & high COF

• Poor scratch and abrasion resistance

• Dust attraction

• Process instability at high output

SILIKE Silicone Additive Benefits:

• Provides dry, silky-soft surface touch

• Maintains long-term low COF without surface coating

• Improves scratch and abrasion resistance

• Enhances extrusion stability

Result:

• Premium tactile feel

• Durable surface

• Higher line productivity

LYSI-406 Silicone Masterbatch for TPE Wire and Cable Compounds

Industry Pain Points:

• Surface tackiness

• Inconsistent slip performance

• Wear & abrasion issues

• Migration of conventional slip agents

SILIKE Silicone Additive Benefits:

• Permanent internal slip

• Migration-free & non-blooming

• Improved abrasion and wear resistance

• Stable long-term performance

Result:

• Soft-touch cables with lasting aesthetics

• Reliable extrusion processing

LYSI-100A Silicone Powder for Low-Smoke PVC Wire and Cable Compounds

Industry Pain Points:

• High friction & poor demolding

• Smoke suppression vs. flexibility trade-off

• Surface roughness & gloss inconsistency

SILIKE Silicone Additive Benefits:

• Reduces friction and improves flow

• Enhances surface smoothness and gloss control

• Supports low-smoke formulations

• Maintains flexibility and mechanical strength

Result:

• Cleaner processing

• Better-looking PVC cable jackets

• Lower smoke performance

LYSI-300P Resin-Free Silicone Additive for LSZH & HFFR Cable Compounds

Application: Pellet S Alternative, No Carrier Limitations

Key Benefits:

• Resin-free design suitable for wide range of polymer systems

• Reduces extrusion torque and die build-up

• Improves melt flow and surface lubrication

• Strong synergy with flame-retardant fillers

Result:

• Stable high-filler LSZH/HFFR extrusion

• Smooth cable surface

• Improved productivity

SC920 Co-Polysilicone Additive for High-Speed LSZH/HFFR Cable Extrusion

Key Benefits:

• Enables higher line speed in LSZH/HFFR extrusion

• Prevents unstable cable diameter

• Reduces screw slippage and process interruptions

• Increases extrusion volume by 10% at same energy consumption

Result:

• High-speed, stable extrusion

• Fewer defects and downtime

SILIMER 6560 Co-Polysilicone Additive for Rubber Cable Compounds

Industry Pain Points:

• Difficult processing & poor flow

• High die wear

• Surface roughness

• Inconsistent extrusion quality

SILIKE Silicone Additive Benefits:

• Improves compound flow and extrusion stability

• Reduces die wear and maintenance

• Enhances surface appearance

• Improves processing efficiency

Result:

• Stable rubber cable extrusion

• Lower operational costs

Relevant Performance Test Evaluations

See How Our Clients Perceive SILIKE’s Silicone Processing Additives and Surface Modifiers —Proven Performance Across Wire & Cable Applications

★★★★★

LYSI-401 – Highly Filled LSZH / HFFR Cable Compounds

"In our HFFR compounding, the ATH/MDH filler loading typically ranges from 50% to 65%. At such high filler levels, a processing additive is essential to ensure good filler dispersion in the polymer matrix and to achieve the required rheological performance.

After introducing SILIKE silicone masterbatch LYSI-401, our HFFR cable compounds demonstrated significantly improved processability, including lower extrusion die pressure, reduced die drool, and more stable extrusion conditions. In addition, the finished cables exhibit durable scratch and abrasion resistance, along with higher extrusion line speed and no additive migration."

— Adam Killoran, Polyolefin Cable Compound Manufacturer

★★★★★

LYSI-502C – Highly Filled LSZH / HFFR Cable Compounds

"High extrusion torque and inconsistent additive dispersion were limiting our LSZH cable production. With SILIKE silicon-based plastics additive LYSI-502C, the lubrication performance is excellent, flame retardants disperse evenly, and surface defects have nearly disappeared. Our extrusion lines now run more smoothly, delivering consistent cable quality."

— Konstantinos Pavlou, Polymer Cable Extrusion Specialist

★★★★★

LYPA-208C – Silane Crosslinking XLPE (Si-XLPE) Compounds

"Premature crosslinking and sharkskin surface defects made Si-XLPE extrusion challenging. Silicone additive LYPA-208C effectively reduced melt friction and surface defects without interfering with silane grafting or crosslinking. We now achieve clean, reliable cable surfaces in every run, improving yield and reducing scrap."

— Manoj Vishwanath, XLPE Compound Manufacturer

★★★★★

LYSI-409 – TPU Cable Compounds (EV Charging, Data & Flexible Cables)

"Sticky surfaces and dust accumulation were major issues in our TPU cable production. After introducing processing additive LYSI-409, the cable surface feels dry, silky, and smooth, with low COF and excellent abrasion resistance. The extrusion process is more stable, and overall line productivity has increased noticeably."

— Emily Williams, EV Cable Producer

★★★★★

LYSI-406 – TPE Wire & Cable Compounds

"Surface tackiness and inconsistent slip performance were affecting our TPE wire production. silicone-based additive LYSI-406 provided permanent internal slip with non-blooming behavior, resulting in smooth, wear-resistant cables and reliable, stable processing."

— Rick Stephens, TPE Compound Manufacturer

★★★★★

LYSI-100A – Low-Smoke PVC Wire and Cable Compounds

"PVC cable jackets previously suffered from high friction and inconsistent surface appearance. Silicone powder lubricant LYSI-100A reduced the coefficient of friction, improved demolding, and enhanced surface smoothness while maintaining flexibility. Low-smoke performance is excellent, and the finished cables now meet both functional and aesthetic requirements."

— Laura Chen, Flexible PVC Compound Manufacturer

★★★★★

LYSI-300P – Resin-Free Silicone Additive for LSZH / HFFR Compounds

"We were looking for a Pellet S alternative without carrier limitations. LYSI-300P Resin-Free performance silicone Additive significantly lowered die pressure, stabilized extrusion, and improved filler dispersion. High-filler LSZH/HFFR cables now extrude smoothly with higher productivity and improved surface quality."

— Taner Bostanci, HFFR Cable Compound Manufacturer

★★★★★

SC920 – Co-Polysilicone Additive for High-Speed LSZH / HFFR Extrusion

High-speed LSZH extrusion often caused diameter instability and screw slippage. High-performance silicone and siloxane additive SC920 enabled higher line speeds, more stable cable dimensions, and reduced downtime. At the same energy consumption, extrusion output increased by approximately 10%.

— Anna Li, LSZH Cable Production Engineer

★★★★★

SILIMER 6560 – Co-Polysilicone Additive for Rubber Cable Compounds

Processing polar rubbers for rubber cable applications was challenging due to poor flow, high die wear, and inconsistent extrusion quality. SILIMER 6560 processing aid improved compound flow, reduced die wear, and enhanced surface appearance, resulting in more stable production and lower operational costs.

— Robert Wang, Rubber Cable Manufacturer

From Compounding to Final Wire and Cable Performance, SILIKE Silicone Additives & Modifiers Help Your Wire and Cable Formulations Achieve Better Processing and Surface Quality.